The Gateway to the Future: JIMTOF 2022

|

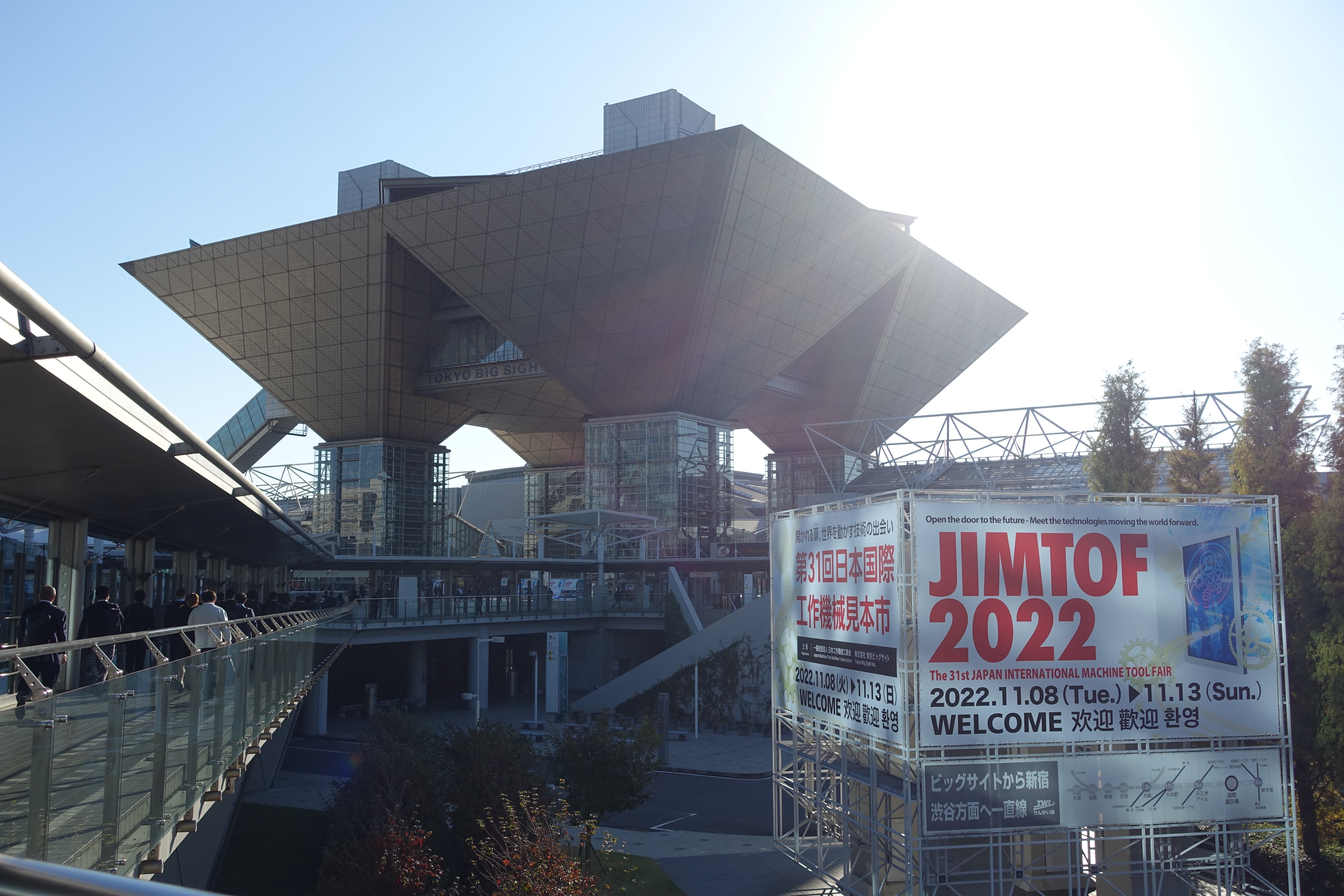

The 31st Japan International Machine Tool Fair (JIMTOF 2022) took place from November 8 to 13. Established in 1962 and held biennially in even-numbered years, JIMTOF is the most influential exhibition in Asia’s machine tool sector. Renowned for Japan's advanced manufacturing technologies, the event consistently attracts global professionals, manufacturers, and buyers, standing as a premier event for the industry.

Exhibition Overview

Organized by the Japan Machine Tool Builders’ Association (JMTBA) and Tokyo Big Sight, the fair returned to a physical format this year after the 2020 edition was moved online due to the pandemic. While "JIMTOF 2020 Online" offered convenience, participants realized that virtual platforms could not replace the experience of seeing machines in person or engaging in face-to-face negotiations.

|

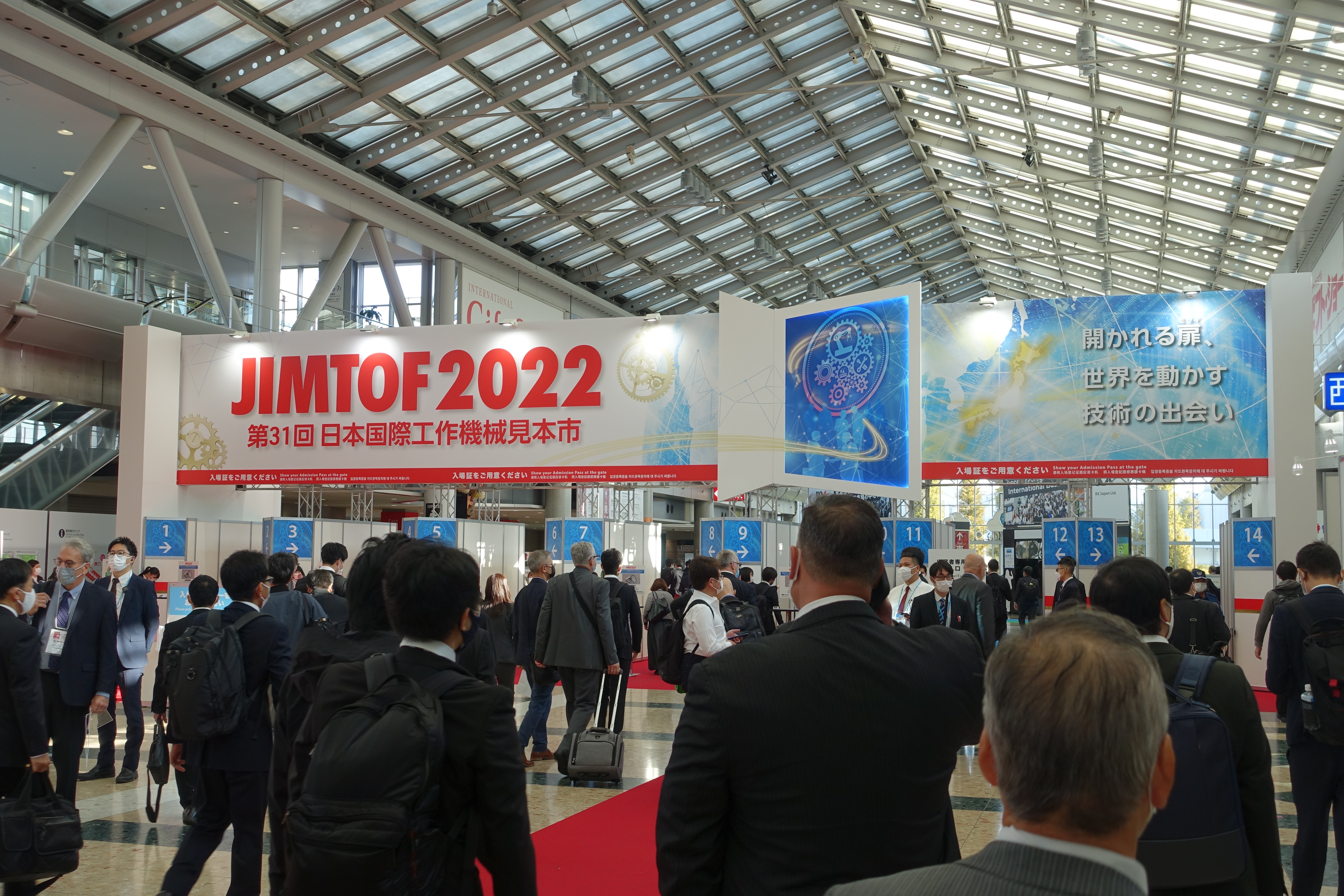

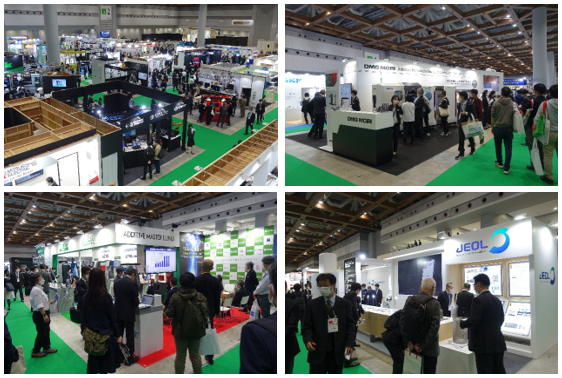

JIMTOF 2022 occupied the East, West, and the newly completed South Halls of Tokyo Big Sight, totaling 118,540 square meters—an increase of 20,000 square meters over the last physical show. According to official data, the event featured 1,086 exhibitors from 22 countries across 5,619 booths, making it the largest JIMTOF in history.

|

The six-day event drew over 110,000 visitors, including nearly 5,000 from overseas. Although attendance was lower than pre-pandemic levels, exhibitors reported high-quality engagement with target clients, viewing the event as a successful "warm-up" for the post-pandemic era. JMTBA President Dr. Yoshiharu Inaba noted that while statistics were lower than 2018, the halls felt more vibrant, likely due to visitors spending more time at each exhibit.

Exhibition Highlights

The theme, "Open the door to the future – Meet the technologies moving the world forward," positioned JIMTOF as a gateway for cutting-edge technology and top talent to converge and drive industrial breakthroughs.

|

-

Highlight 1: The "AM Area" (Additive Manufacturing) Additive Manufacturing (AM) has evolved from prototyping to end-product manufacturing, particularly in the medical and mold industries. Precedence Research predicts the global metal AM market will grow from $2.54 billion in 2021 to $11.45 billion by 2030. To address this, JIMTOF 2022 introduced a dedicated AM Area in the South Hall, featuring 59 exhibitors and 173 booths showcasing specialized hardware and software for complex geometries.

|

-

Highlight 2: Progress in Digital Transformation (DX), Visualization, and Automation The trend toward smart manufacturing is accelerating. By integrating IoT and AI, manufacturers are visualizing production data and automating processes from design to assembly. Sensors now analyze machine status and provide feedback to optimize tool paths, while IoT links equipment with robots and AGVs to enhance efficiency.

-

Highlight 3: Green Transformation (GX) and Sustainability Carbon neutrality and "Decarbonization" (脫炭素化) were central topics. GX in machine tools focuses on two paths: Improving Production Efficiency (e.g., using multi-tasking machines to complete processes in a single setup) and Reducing Energy Consumption (e.g., monitoring operations to power down peripherals like hydraulic pumps and chip conveyors during idle times).

|

Major Japanese Exhibitor Highlights

-

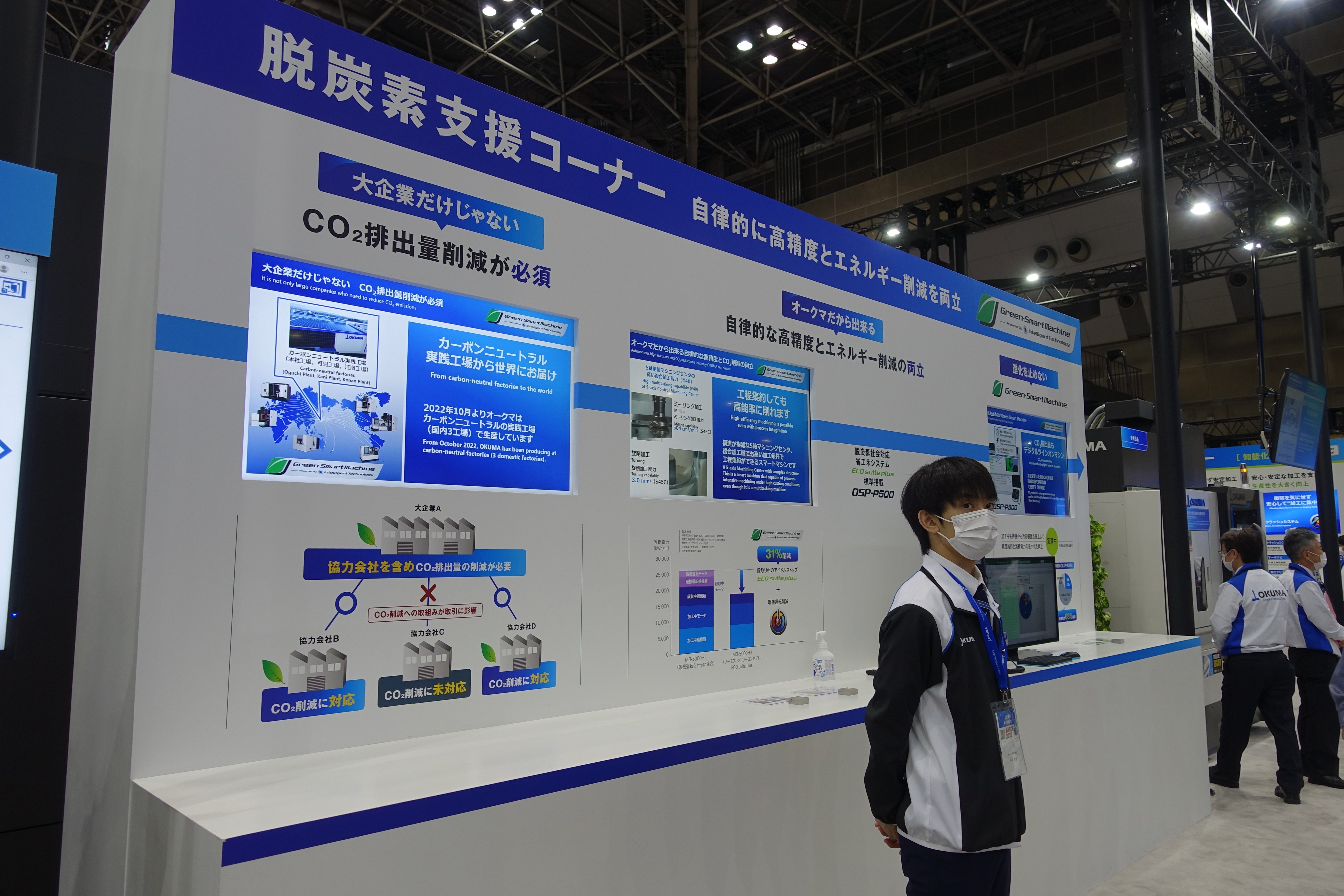

OKUMA: Focused on Automation, Decarbonization, and Digitalization. They introduced the "Green-Smart Machine" label for eco-friendly equipment and the OSP-P500 controller, which features Digital Twin technology for advanced processing simulation.

|

|

-

FANUC: Showcased five areas including Factory Automation (FA) and IoT. The highlight was the upgraded "FIELD system Basic Package," designed to help manufacturers easily implement IoT monitoring.

|

|

-

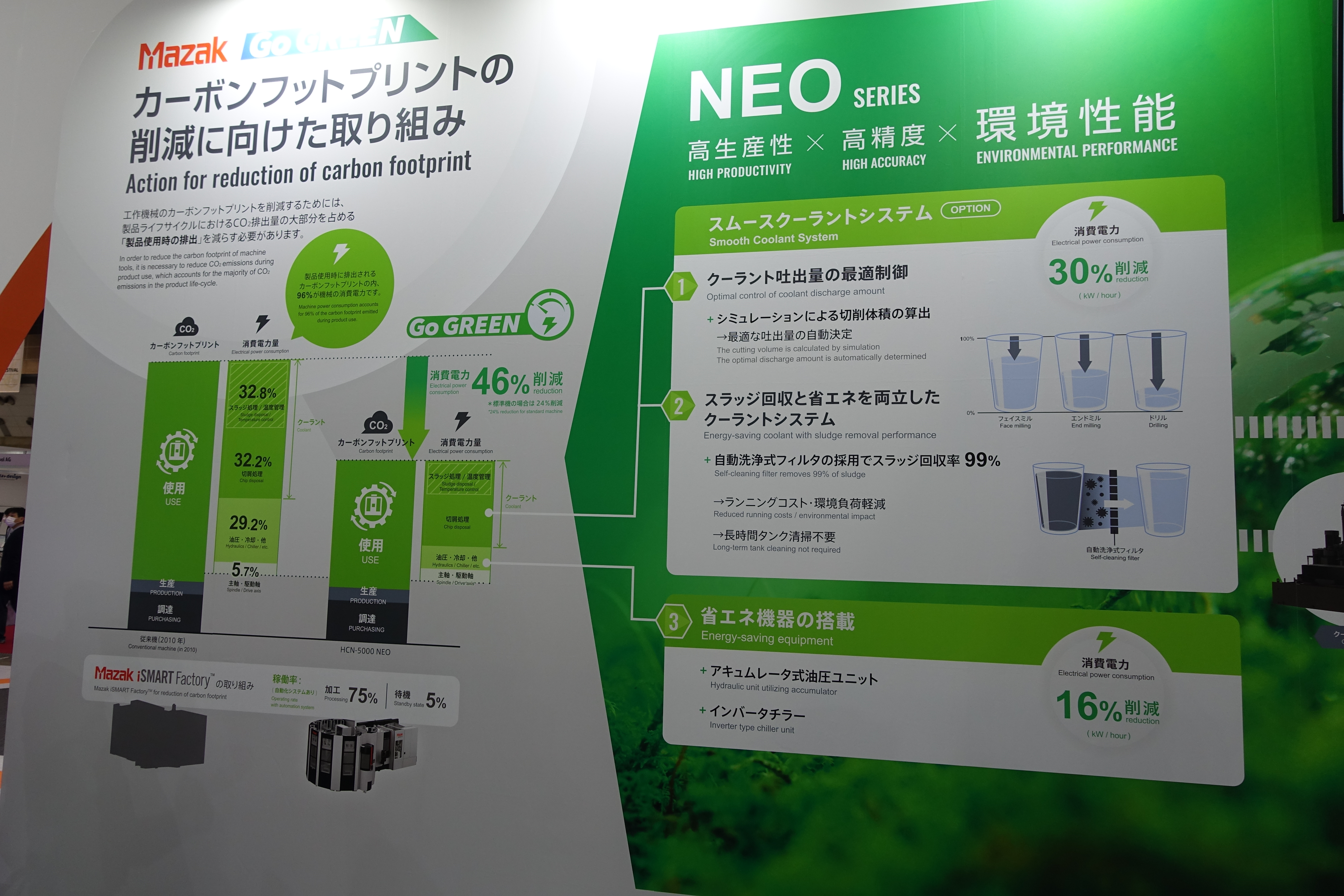

MAZAK: Under the slogan "Go Green," MAZAK presented digital solutions aimed at carbon neutrality. They aim to reduce their carbon footprint by 50% by 2030 compared to 2010 levels, showcasing 19 machines including 5-axis and laser cutters.

|

|

-

DMG MORI: Occupied almost the entire East Hall 8, highlighting the WH-AMR (Autonomous Mobile Robot) and the zeroFOG oil mist collector. Notably, DMG MORI achieved SBT (Science Based Targets) certification in 2021, reaching carbon neutrality across its global factories.

|

|

-

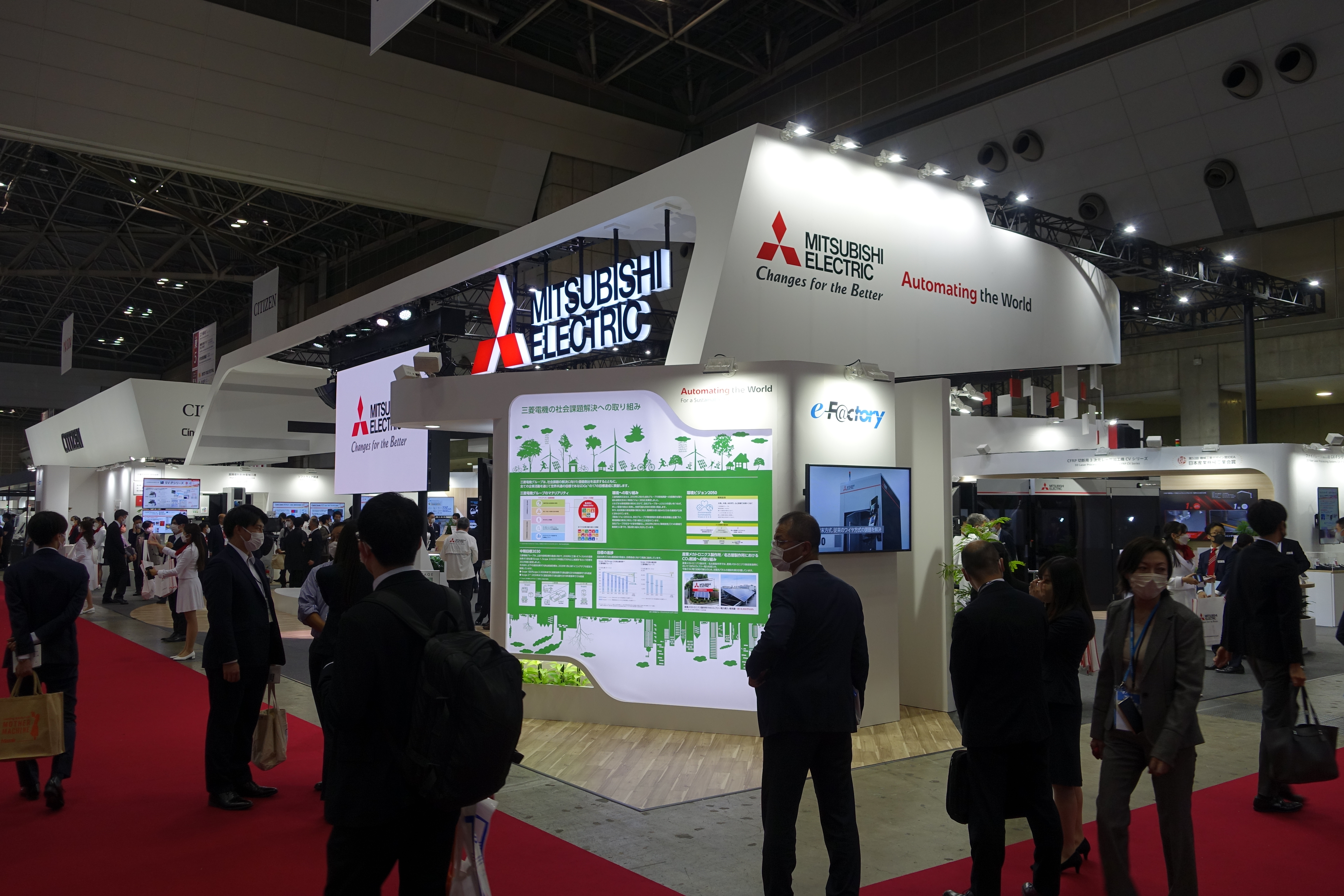

MITSUBISHI ELECTRIC: Featured the theme "Smart Manufacturing through Evolution." They launched the M800V/M80V series controllers for high-speed precision and the CV series laser machine, specifically designed for high-efficiency cutting of CFRP (Carbon Fiber Reinforced Polymer).

|

Economic Status and Trends in Japan

Economic Outlook and Industry Forecast

The JMTBA reported that Japan’s GDP grew 0.9% in Q3 2022 as COVID-19 restrictions eased. However, the economy faces challenges from global monetary tightening, inflation, and market volatility.

|

Orders and Trends

From January to September 2022, Japanese machine tool orders reached 1.34 trillion JPY, a 21.3% increase year-on-year. Domestic orders rose 31.2%, driven by demand for semiconductor and EV components, while foreign orders reached a post-2018 high of 873 billion JPY, primarily from North America and Asia.

While strong order books are expected to last through March 2023, the industry remains cautious. Risks such as the Russia-Ukraine war, China's economic uncertainty, component shortages, and shipping delays may lead to a cooling of orders in the future.