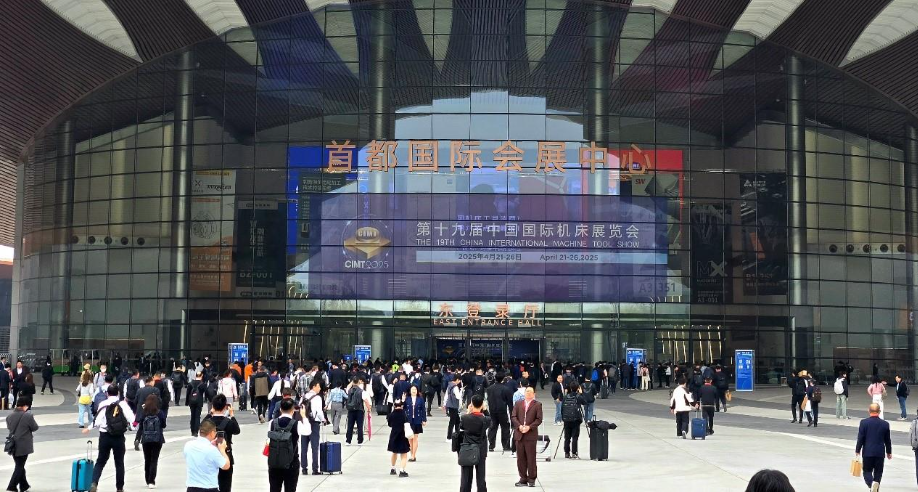

CIMT 2025: Dual-Venue Exhibition Sets Historical Record; Smart Manufacturing, Automation, and Green Transformation Lead Machine Tool Trends

The 19th China International Machine Tool Show (CIMT 2025) was held grandly in Beijing from April 21 to 26, 2025, serving as a vital barometer for the global machine tool industry. This edition marked the first time the event utilized a "dual-venue" format, spanning both the China International Exhibition Center (Shunyi Hall, Phase I) and the new Phase II venue. The total exhibition area reached a record-breaking 310,000 square meters, making it the largest in the past decade.

The exhibition attracted 2,432 exhibitors from 31 countries and regions, including national pavilions from 13 regions such as the United States, Germany, Japan, and Taiwan. Exhibits covered the entire industrial chain, including metal cutting and forming machine tools, laser processing, 3D printing, industrial robots, CNC systems, precision tools, and measurement equipment. Total visits reached 416,570, with 211,993 unique visitors—a significant increase over CIMT 2023, reaffirming its status as one of the world's four major machine tool exhibitions.

|

Three Core Trends Driving the Industry

Continuing the theme of "Integrated Innovation, Digital & Intelligent Future," the show highlighted three core trends: the deepening of smart manufacturing, the ubiquity of automation solutions, and the emergence of green transformation.

1. The Automation Wave Hits the Floor

Automation was the primary highlight. China’s Gree Electric showcased a system linking robotic arms with machine monitoring to enable automatic fault skipping and intelligent loading/unloading. Beijing Jingdiao presented a complete automated line consisting of machining centers, automatic supply systems, and robots. Pratic exhibited a fully automated unmanned production system paired with gantry robots, emphasizing the integration of "automation + precision machining."

From Japan, Mazak demonstrated its "DONE IN ONE" philosophy, where a single machine handles all processes from raw material to finished product, reflecting the trend of process intensive development. South Korea’s DN Solutions also centered its showcase on "automation as the core," positioning it as the key solution for labor shortages and productivity enhancement.

|

2. Digital Transformation and AI Origins

Digital transformation has matured, with remote monitoring, process parameter optimization, and digital twin pre-commissioning becoming more refined. China’s Shandong Dahan utilized multi-platform apps to give customers real-time access to factory output and scheduling. DMG MORI continued its vision from JIMTOF, placing digital transformation at the heart of "Machining Transformation (MX)."

Artificial Intelligence (AI) also made its mark. Technology that uses AI to recognize engineering drawings and automatically generate machining parameters and code has slashed debugging time for new workpieces from 48 hours to just 4 hours. Japan’s OKUMA showcased an AI tool monitoring system capable of issuing warnings before a failure occurs, demonstrating AI’s potential to elevate machine tool intelligence.

3. Obvious Trend Toward Process Integration

"Process Integration" aims to improve precision and efficiency while reducing floor space and labor by consolidating multiple functions into one machine. Citizen (Japan) exhibited a sliding head lathe for medical components equipped with 12 tools for high integration. Schütte (Germany) showcased a specialized machine for automotive alternators featuring 9 spindles and multiple turrets, capable of simultaneous machining with 18 tools.

Regional Differences in Green Transformation

Green transformation showed a clear regional divide. While Chinese manufacturers had fewer displays in this area, Japanese and Korean giants were proactive. OKUMA’s machines can automatically detect thermal deformation and adjust machining positions, reducing reliance on air conditioning and lowering carbon emissions. For many, improving energy efficiency and reducing waste remain core challenges, though the level of investment currently varies by country.

The Growing Importance of the Chinese Market

The Chinese government has designated machine tools as a priority industry, fueling continuous technological upgrades. Emerging sectors like 3C electronics, NEVs (New Energy Vehicles), drones, aerospace, and humanoid robots provide a wealth of applications for high-end equipment.

China is not only one of the world's largest markets but also a platform for global firms to debut cutting-edge tech. DMG MORI has even established a production base in China to shorten lead times and improve service. The show also highlighted the unique business model of Chinese vendors: utilizing local components and fast payment strategies to drive down supplier costs, creating a significant price advantage.

Industry-Academia Collaboration and International Exchange

The "2025 Machine Tool Manufacturing CEO Forum" gathered global leaders to discuss supply chain restructuring. Meanwhile, the CMTBA (China) and VDW (Germany) held technical exchanges for NC-Link and umati, focusing on industrial IoT standardization. The "University Window" featured research from prestigious institutions like Tsinghua University in fields like five-axis and ultra-precision machining.

|

Strategic Layout of Taiwanese Manufacturers

-

YCM showed five-axis machines with automation modules.

-

Tongtai presented smart turn-mill multitasking machines integrated with software.

-

Quaser demonstrated high-flexibility five-axis equipment.

-

HIWIN focused on green tech and integrated smart manufacturing solutions.

|

|