The Cornerstone of Competitive Advantage: Applying Cutting Force Sensing Technology Toward High-Value Manufacturing

How Much Time Does Taiwan Have Left? The Urgency of Transformation in Precision Machining

Taiwan’s precision machining industry stands at a critical crossroads. For decades, through superior technology and flexibility, Taiwan has played an indispensable role in the global manufacturing supply chain. However, shifts in global economic pulses are presenting unprecedented challenges. On one hand, standardized CNC machining orders continue to migrate to lower-cost regions, placing immense pressure on traditional business models that rely on volume and price competition. On the other hand, geopolitical shifts and supply chain restructuring are driving the global high-tech industry to seek partners who are more stable, reliable, and technologically advanced.

In this context, simple manufacturing is no longer enough for Taiwanese machining enterprises to maintain competitiveness and achieve sustainable growth. The direction of transformation is clear: companies must upgrade from traditional "Make-to-Print" suppliers to "Data-Driven Manufacturing Partners" capable of providing process assurance and data analysis. This shift is not just a technical upgrade but a fundamental change in business models. High-value industries, such as aerospace and semiconductors, do not merely purchase a metal part that meets drawing dimensions; they purchase confidence in process stability, quality consistency, and full traceability. This is precisely where cutting force sensing technology exerts its strategic value.

Whether facing the "heavy-force" challenges of aerospace or the "micro-force" controls of semiconductors, the common supreme principle is the requirement for "Zero Defect" quality and complete process traceability. The failure of a single part can shatter confidence in the machine shop, as downstream costs far outweigh the value of the part itself. Consequently, customers no longer demand just a pre-shipment inspection report; they require evidence that every second of the manufacturing process remained under control. Cutting force data, as the most direct and real-time record of physical machining behavior, becomes the core of this "Digital Quality Certificate." With the global aerospace supply chain projected to reach $1.5 trillion and the semiconductor market exceeding $600 billion by 2025, Taiwanese enterprises can break through barriers and achieve sustainable growth by implementing sensing technologies.

Cutting Force: The Key Driver Behind Process Breakthroughs

Machines and tool holders require high rigidity because forces generated during cutting cause vibrations. Insufficient rigidity amplifies errors and affects machining precision. For example, the abnormal noise emitted when a tool wears stems from the uneven distribution of cutting forces, leading to increased friction and material stress concentration. Conversely, machining hard and brittle materials too quickly causes fracturing because the cutting force exceeds the material’s fracture toughness, triggering micro-crack propagation.

The core of these phenomena is cutting force—the critical factor in machining technology that determines process stability, tool life, and finished product quality. Different tool diameters, coating materials, tool holder structures, spindle designs, and the non-linear characteristics of metals or the brittle-to-ductile transition curves of hard materials all correspond to specific cutting force limits. This is the underlying logic behind the machining strategies accumulated by factories over many years. Through cutting force monitoring, these variables can be predicted and optimized to avoid waste and defects.

Pursuing lower costs is no longer an effective way to gain competitiveness. The key to transformation and profit growth lies in effectively quantifying and inheriting the experience of master craftsmen, and managing machining strategies—such as coordinating parameters and tooling—to achieve higher Material Removal Rates (MRR).

Applications of Cutting Force Sensing Technology

In the field of 5-axis machining for aerospace Blisks, scholars have applied the SPIKE sensing tool holder from the German company Pro-micron for online monitoring. In research published in the journal Science Progress, Lee et al. utilized the SPIKE wireless tool holder to analyze cutting forces in real-time during Blisk roughing, evaluating spindle runout and tool clamping status. By using force signals provided by the sensing tool holder, they optimized 5-axis paths and machining strategies, reducing total machining time by 16.5%.

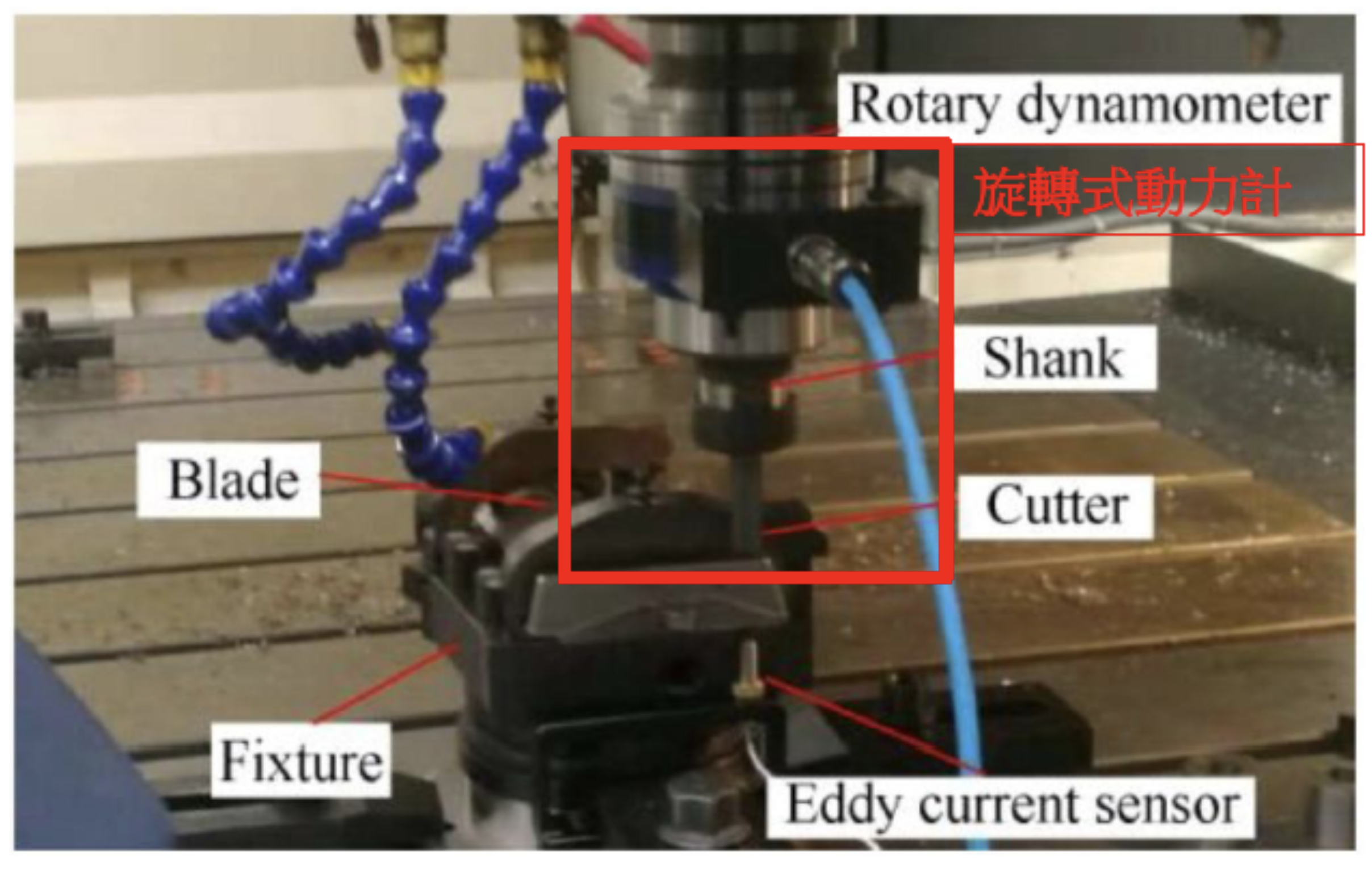

Another study on "Near-Net-Shape Adaptive CNC Machining of Jet Engine Blades" developed and verified adaptive control technology for CNC processes and tools for complex, high-precision aerospace needs. This technology has been directly applied by frontline national aerospace engine manufacturing units. The research implemented a rotary dynamometer from Kistler (Switzerland) to quantify cutting forces during 5-axis blade machining, allowing for the design of fixtures and clamping sequences that achieve high-precision manufacturing, effectively solving challenges related to low rigidity and positioning.

|

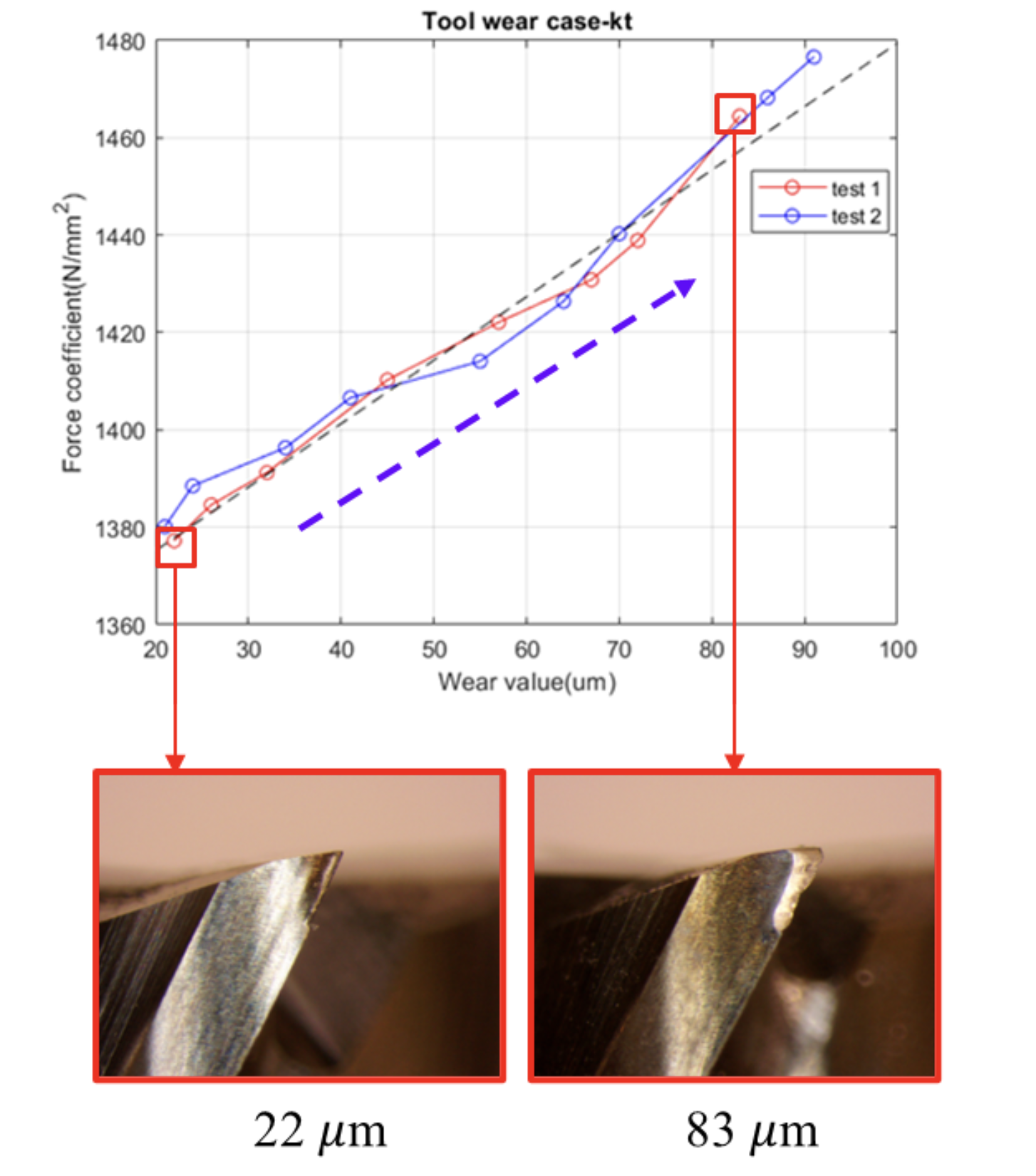

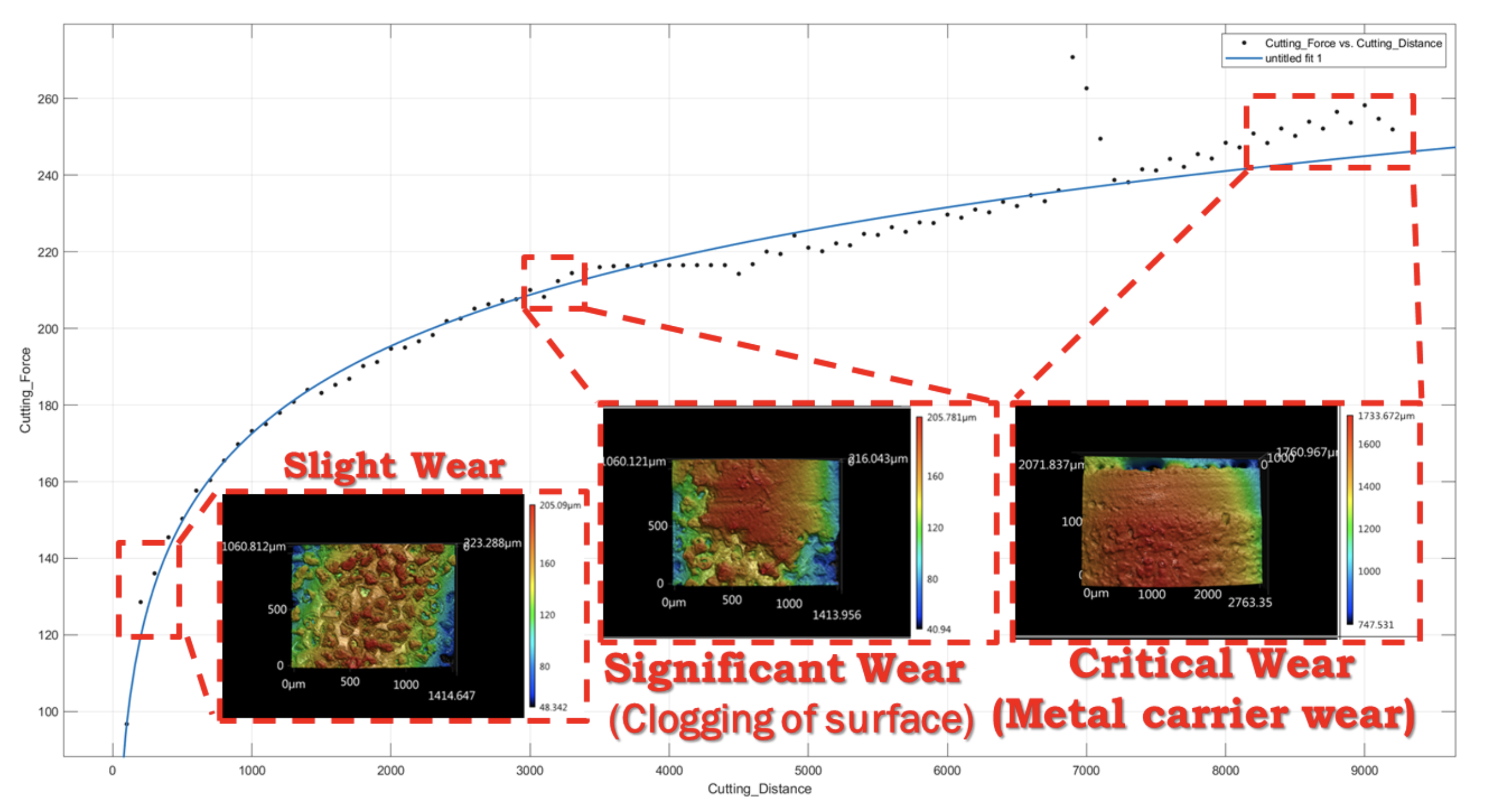

Beyond cutting nickel-based alloys, cutting force sensing tool holders have been tested on metal tool wear and diamond grinding points for Alumina (Al₂O₃) ceramics. Both tests effectively detected the relationship between tool wear and cutting force in real-time. In brittle material machining, the tool holders provided by Wollong Industrial, equipped with high-precision sensors, monitor mechanical data in real-time. This shows significant advantages when processing high-hardness materials like Alumina ceramics. Test results indicate that the sensing tool holder can accurately capture the transition phases from slight wear to severe wear, showing a high correlation with cutting force trends. This helps optimize parameters and prevents workpiece damage or quality degradation caused by excessive tool wear.

To further verify reliability, Wollong conducted multiple test sets involving metal tools and diamond grinding points under various conditions. The results consistently showed that the detection accuracy of the sensing tool holder is higher than traditional methods. The system supports seamless integration with CNC machines, alerting operators to abnormal wear via automated alarms. It can also integrate with controllers to achieve automatic shutdown and real-time adjustment to optimal machining parameters. In the future, with the establishment of a "Knowledge Graph," cutting force sensing technology will be applied to a wider range of material processing scenarios, combined with AI algorithms to enhance predictive capabilities and drive the development of intelligent manufacturing.

|

|

A Glorious Past, A Brilliant Future

Our predecessors created Taiwan’s economic miracle by overcoming diverse hardships. As machining becomes increasingly complex and difficult, we have every reason to believe that cutting force monitoring will be the process key for next-generation complex machining. Companies like Pro-micron (Germany), Kistler (Switzerland), and Wollong (Taiwan) have gathered sufficient evidence through clinical trials to prove that cutting force sensing systems are powerful tools for optimizing manufacturing. By precisely analyzing tool edge angles and coating behaviors, manufacturers can systematically optimize product performance and ensure stability. The road is long and difficult, but by taking the right steps, we will reach our destination.