The Benefits of Regular Annual Machine Tool Calibration

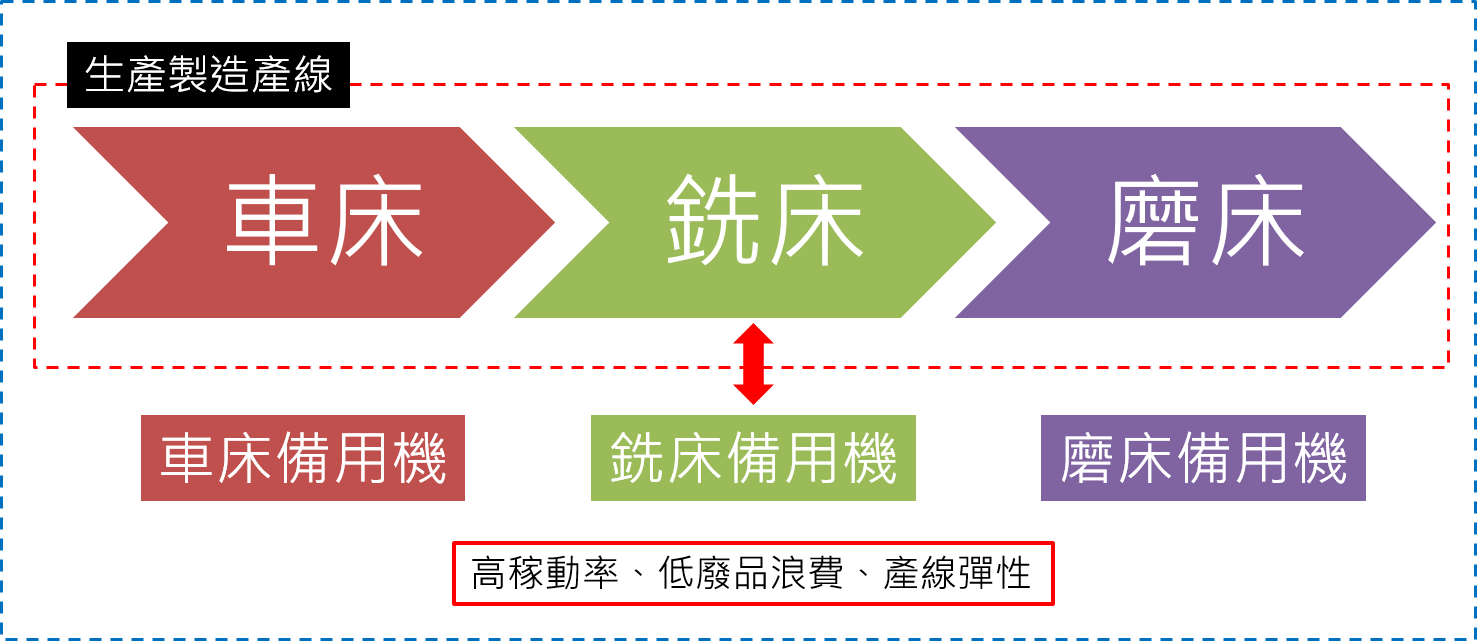

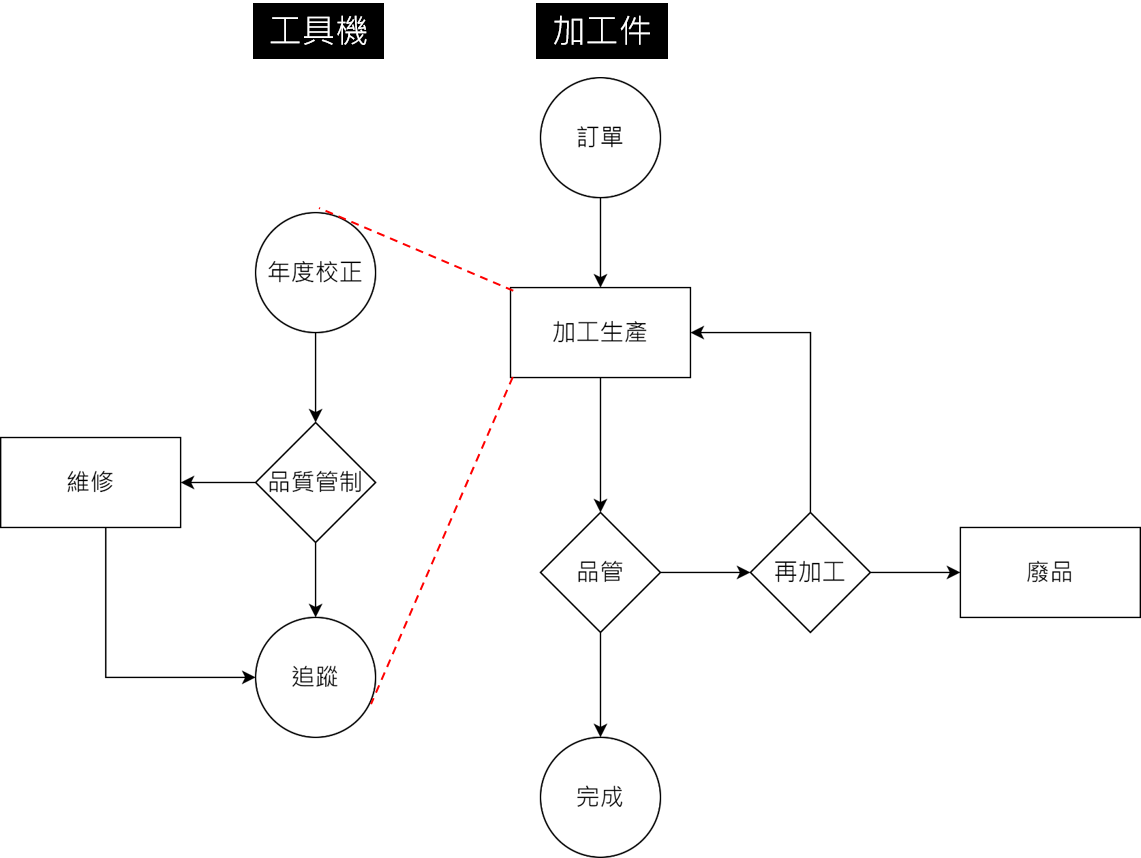

Machine tools are widely used across various industries. Once a processing plant receives an order, production scheduling is typically managed manually or through a Manufacturing Execution System (MES). While simple workpieces can be completed by a single machine, complex parts require multiple machines. Consequently, any accuracy deviation in a machine tool within the production line can lead to defective parts, wasting time and increasing management costs. The condition of each machine is critical; therefore, factories can ensure smooth production through annual machine tool calibration. This allows for scheduled maintenance, the activation of backup machines, and a reduction in defect rates, ultimately achieving high availability, production flexibility, and minimized waste (as shown in Figure 1).

|

Annual Calibration Inspection Items

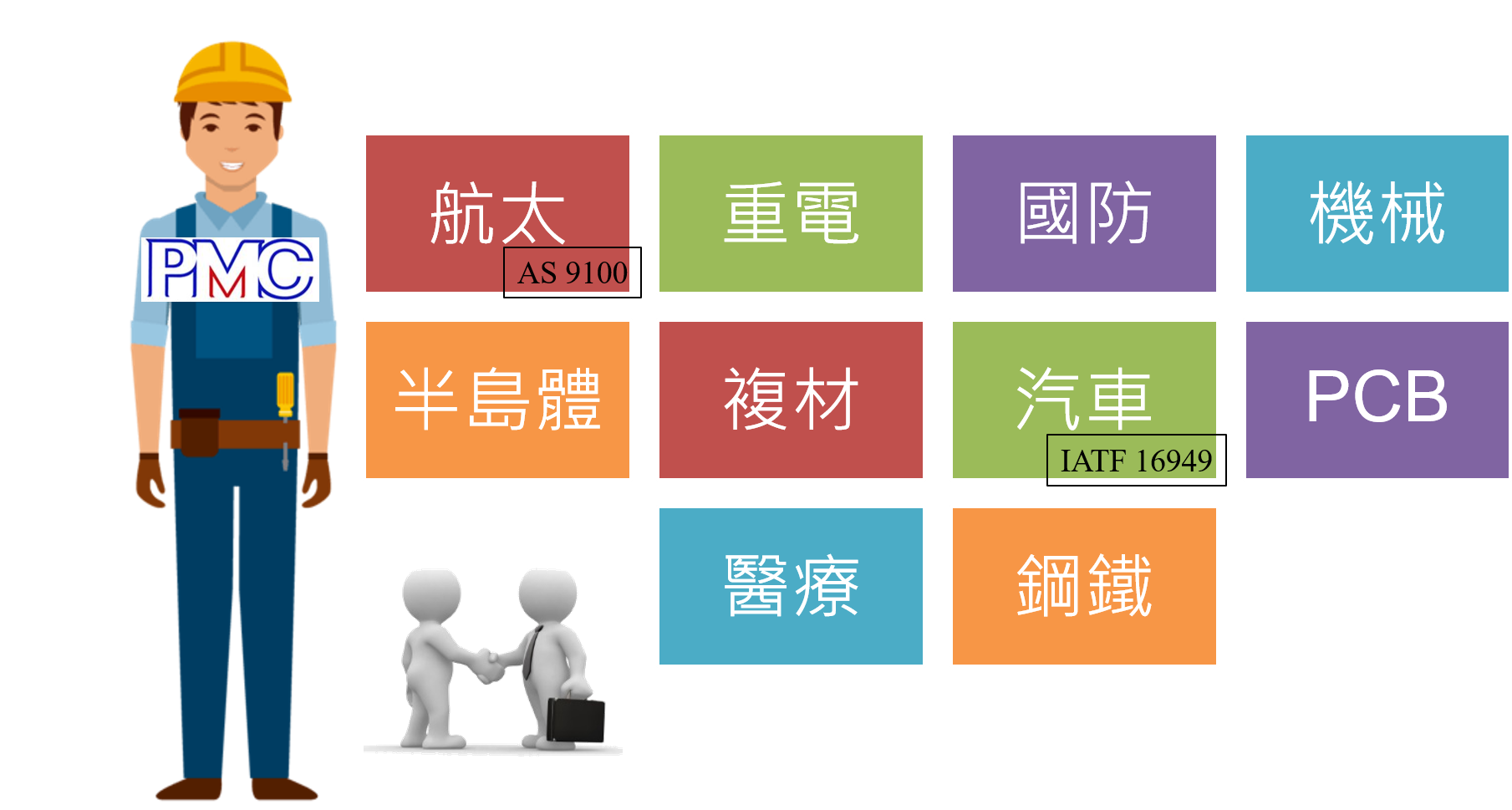

The Machine Testing Department has served diverse sectors, including aerospace, heavy power, defense, machinery, semiconductors, composites, automotive, PCB, medical, and steel (as shown in Figure 2). Industry operators can utilize annual calibration for self-management and quality tracking, implementing international quality management standards such as IATF 16949 for automotive and AS 9100 for aerospace to align with global requirements. New industries or operators may consult the Machine Testing Department for specific needs.

|

Processing plants often possess machines of different brands, models, configurations, and stroke sizes, requiring systematic management. After annual calibration, inspection data is used for quality control analysis. Calibration should be performed periodically to identify the machine's level of performance or determine if maintenance is required, achieving the goal of "downtime without work stoppage" and ensuring production efficiency. When the sample size is small, analysis only reveals trends; as the sample size increases, specific analysis of a single model or machine becomes possible, allowing for precise problem identification. If accuracy levels approach the Upper Control Limit (UCL), further analysis, monitoring, or scheduled maintenance is initiated.

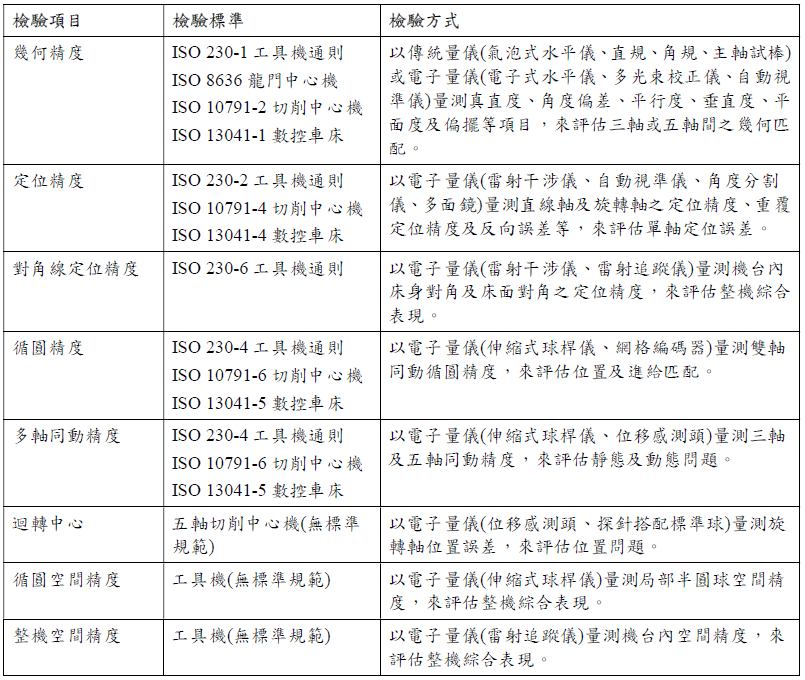

Basic machine tool accuracy inspection items, such as geometric accuracy, positioning accuracy, diagonal positioning accuracy, circular tests (ball bar), and multi-axis simultaneous motion accuracy, all correspond to ISO international standards. Specialized inspections include circular spatial accuracy, full-machine spatial accuracy, and center of rotation, which provide a comprehensive evaluation of the machine and ensure multi-axis machining precision. Detailed inspection items are listed in Table 1.

|

Annual Calibration Quality Control Case Study

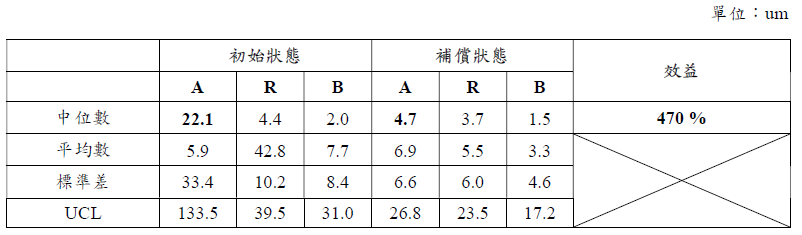

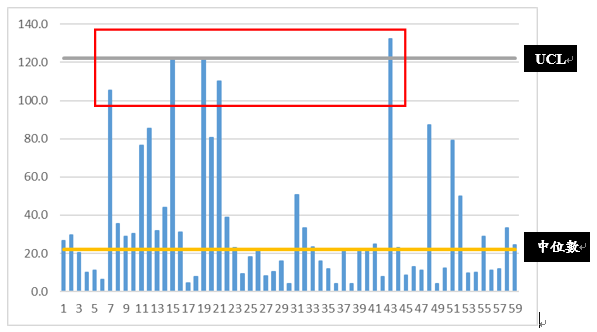

In a defense industry case study involving 23 machine tools of various brands and types, linear axis positioning accuracy was inspected according to ISO 230-2. Measurements were taken in both the initial state (two bi-directional runs) and the compensated state (five bi-directional runs). Data from 59 axes were analyzed to calculate the mean, median, and standard deviation. Due to the complexity of the samples and wide data distribution, the standard deviation was large; therefore, the median was used for the quality control chart analysis to avoid influence from extreme outliers. Overall, the positioning accuracy in the compensated state improved by 470% compared to the initial state (as shown in Table 2), demonstrating the significant effect of annual calibration.

|

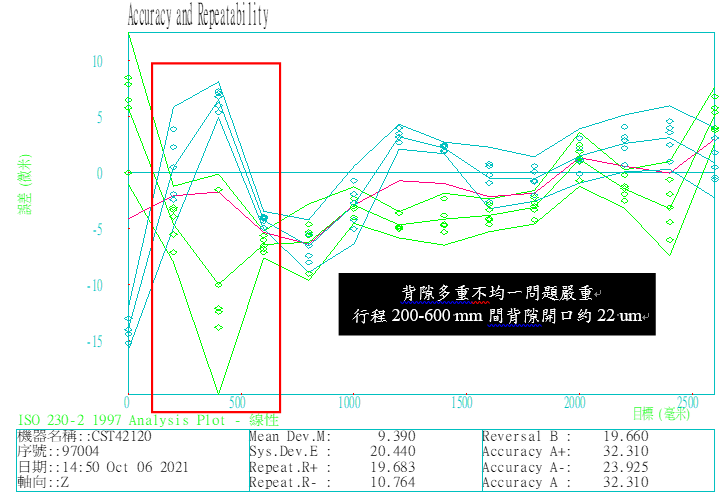

A quality control chart based on the initial positioning accuracy (Figure 3) identified 5 machines with accuracy levels near the UCL. Further inspection showed that 4 of these improved significantly after compensation, but Machine 1 remained problematic. Analysis of Machine 1's data (Figure 4) revealed severe non-uniform backlash, with a gap of approximately 22 μm between the 200–600 mm stroke range.

|

|

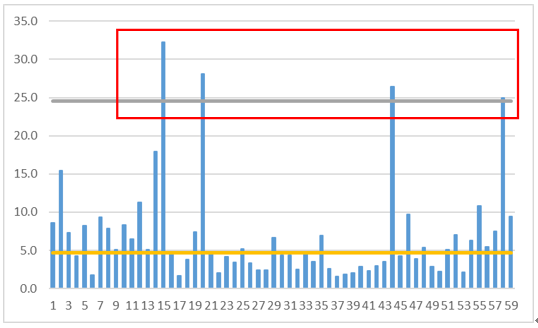

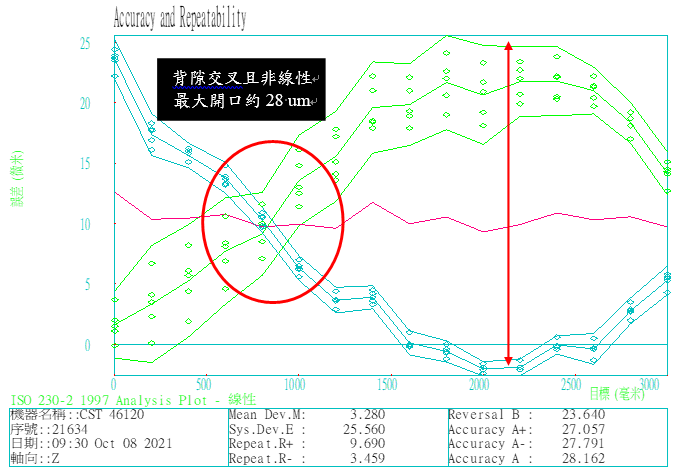

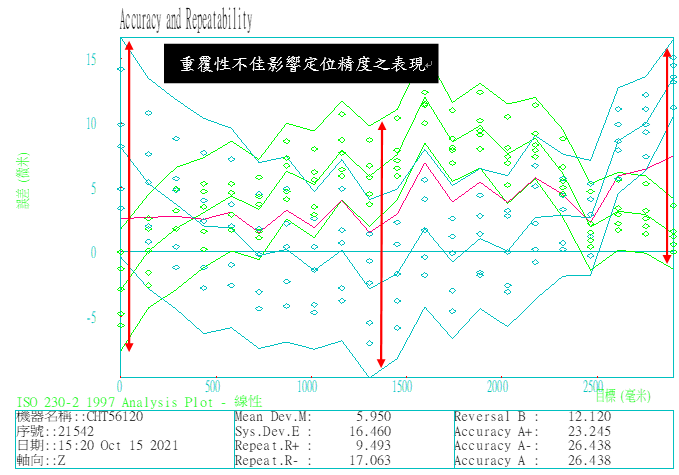

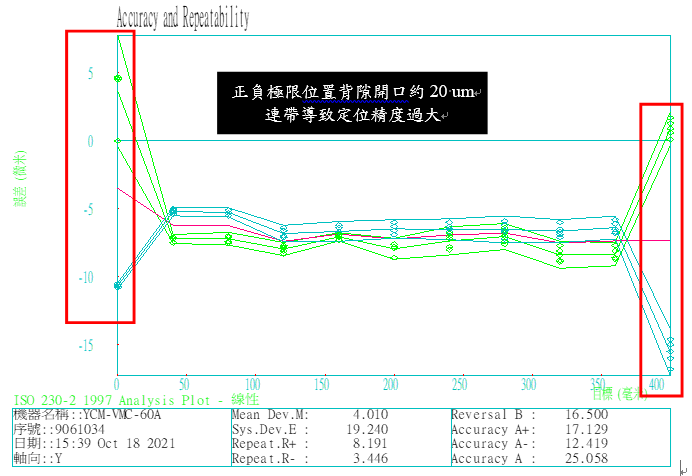

After compensation, the quality control chart (Figure 5) showed 4 machines still exceeding the UCL. Among them, Machine 2 (Figure 6) exhibited crossed and non-linear backlash with a maximum gap of 28 μm; Machine 3 (Figure 7) showed poor repeatability; and Machine 4 (Figure 8) had a 20 μm backlash gap at the positive/negative limits, resulting in excessive positioning error.

|

|

|

|

By applying quality control methods to the 59 axes of the 23 machines, anomalies were identified in 4 units. Detailed analysis provided specific recommendations: axes with issues that do not currently affect machining precision are monitored, while those likely to impact quality are scheduled for maintenance, optimizing factory resources. The results of the annual calibration analysis are summarized in Table 3.

|

Conclusion

Implementing regular annual calibration for machine tools (Figure 9) ensures smooth production after receiving orders. Through quality control techniques and accumulated data, factories can track machine conditions and quickly identify faulty equipment. This proactive approach—scheduling repairs and utilizing backup machines—minimizes downtime, reduces defect rates, and prevents waste. Annual calibration achieves high availability, low waste, and production line flexibility. These services can be customized based on factory needs, including workpiece characteristics, specific inspection items, quality control plans, and calibration cycles.