Edison Awards Silver Medal Winner: AI Optimization Technology for Advanced Aerospace Electrical Discharge Machining

A New Breakthrough: Integrating AI into Critical Aerospace Manufacturing Processes

Electrical Discharge Machining (EDM) is a critical process in aerospace manufacturing. Traditionally, it has relied heavily on manual experience for parameter tuning, a tedious process that lacks real-time optimization, significantly impacting efficiency and precision. This study developed "AI-Optimized EDM Equipment for Aerospace," utilizing AI self-adaptive technology to pioneer the intelligent adjustment of EDM parameters, enabling real-time monitoring and compensation mechanisms. This innovation reduces finishing time by over 50% and enhances machining precision to within 5 μm. It drives the efficiency and precision upgrades of aerospace-grade components, representing a revolutionary breakthrough for high-end manufacturing. Furthermore, the equipment integrates AIoT centralized management for cross-border remote data monitoring and creates production logs to ensure stability and global supply chain responsiveness. The technology has been implemented by several manufacturers, including First EDM and Joemars, successfully applied to key aerospace engine components and the intelligent upgrading of high-end electric vehicle (EV) connector terminal molds.

Challenges in Machining Aerospace Materials

The aerospace industry has long maintained rigorous quality system certifications and highly complex integration technologies; nations generally view it as a key indicator of industrial technical capability. Regarding the cost structure of aircraft components, engines account for approximately 27% of total costs, second only to the airframe (38%). Taking the Boeing 757 as an example, the primary materials for its engines are titanium alloys (~38%) and nickel-based alloys (~37%). Material selection is crucial for ensuring jet engines operate normally under high-temperature and high-load conditions. However, while titanium and nickel-based alloys possess excellent mechanical properties at high temperatures, their high strength, low thermal conductivity, and susceptibility to work hardening make milling difficult. Challenges such as high cutting forces, poor heat dissipation, excessive tool temperatures, and accelerated tool wear limit machining efficiency and stability. Specifically, for superalloy impeller parts with complex twisted surfaces and thin-plate features, the technical barrier is even higher, making this a critical area where aerospace manufacturers urgently seek breakthroughs.

Limitations of Traditional Electrical Discharge Machining (EDM)

As the aerospace industry trends toward high performance, lightweighting, and high reliability, critical components often utilize hard alloys, heat-resistant, and difficult-to-machine materials. Precise forming and micro-structure manufacturing frequently rely on EDM as the final critical process. Currently, EDM processes in aerospace face complex parameter combinations and a high reliance on senior technicians' experience, leading to difficulties in knowledge transfer and increased labor-dependency risks. Additionally, issues such as prolonged machining times, unstable discharge, abnormal electrode wear, and fluctuations in quality often occur, affecting product yield and delivery schedules. Facing the extreme quality demands of the aerospace industry, along with requirements for traceability, process consistency, and increasingly strict international certifications, traditional EDM methods can no longer support high-end manufacturing needs.

While EDM offers high-precision capabilities suitable for high-hardness materials, its efficiency still has room for improvement. In contrast, Electrochemical Machining (ECM) offers high speed and is suitable for preliminary processes, followed by EDM to achieve final precision. This hybrid manufacturing model can be applied to mold making and the high-efficiency machining of large workpieces made of high-hardness materials (e.g., Inconel 718) in the aerospace sector. This study introduces cross-process intelligent integration technology. By analyzing pulse signals and combining intelligent sensor data fitting with dimensional measurement analysis, key machining features are extracted to establish predictive models. Virtual sensing is then used to compensate for errors generated across processes, ensuring the dimensional stability of the final product. This achieves precise matching between pre- and post-processes, providing a fast and scientific intelligent machining solution expected to reduce processing time by approximately 80% and achieve a precision prediction capability of 0.01 mm².

How AI Intervenes in the EDM Process

Currently, the production of high-end aerospace products requires EDM for the final critical steps. However, traditional EDM parameters are complex and experience-dependent, often facing issues like long machining cycles, insufficient process stability, and severe electrode wear. To address these, our AI optimization technology features two major innovations: First, the establishment of AI Intelligent Optimization, solving the problems of trial-and-error in finishing processes, which are costly, time-consuming, and lack real-time feedback. Second, the integration of Big Data, AI computation, and Domain Knowledge under an AIoT cloud service architecture, allowing for remote monitoring of existing equipment to achieve more efficient and stable production.

The technology integrates process sensor data, machining history, and AI machine learning models to build a self-learning parameter optimization mechanism. By analyzing discharge states and electrode wear in real-time, it dynamically adjusts key parameters to shorten machining time, enhance stability, and reduce electrode consumption. Unlike traditional EDM, this technology serves as an "adaptive aerospace-grade intelligent machining equipment" featuring "machining-measurement-compensation" functions, including microsecond-speed analysis of key parameters, online quality prediction, and real-time feedback for optimization.

|

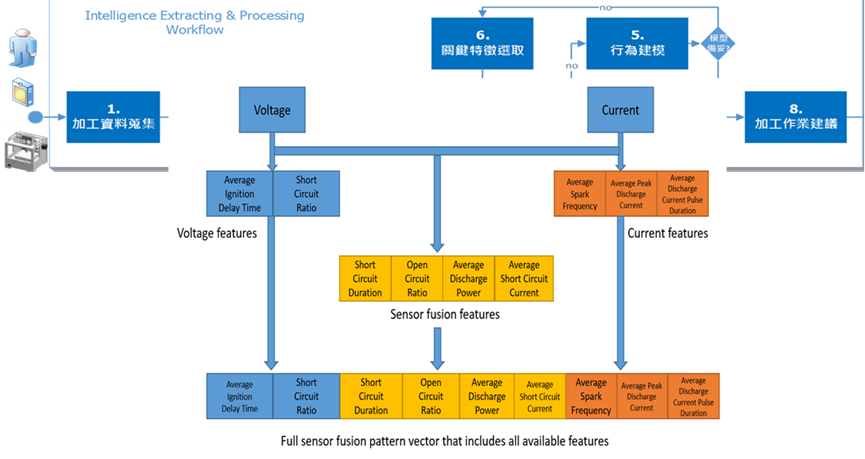

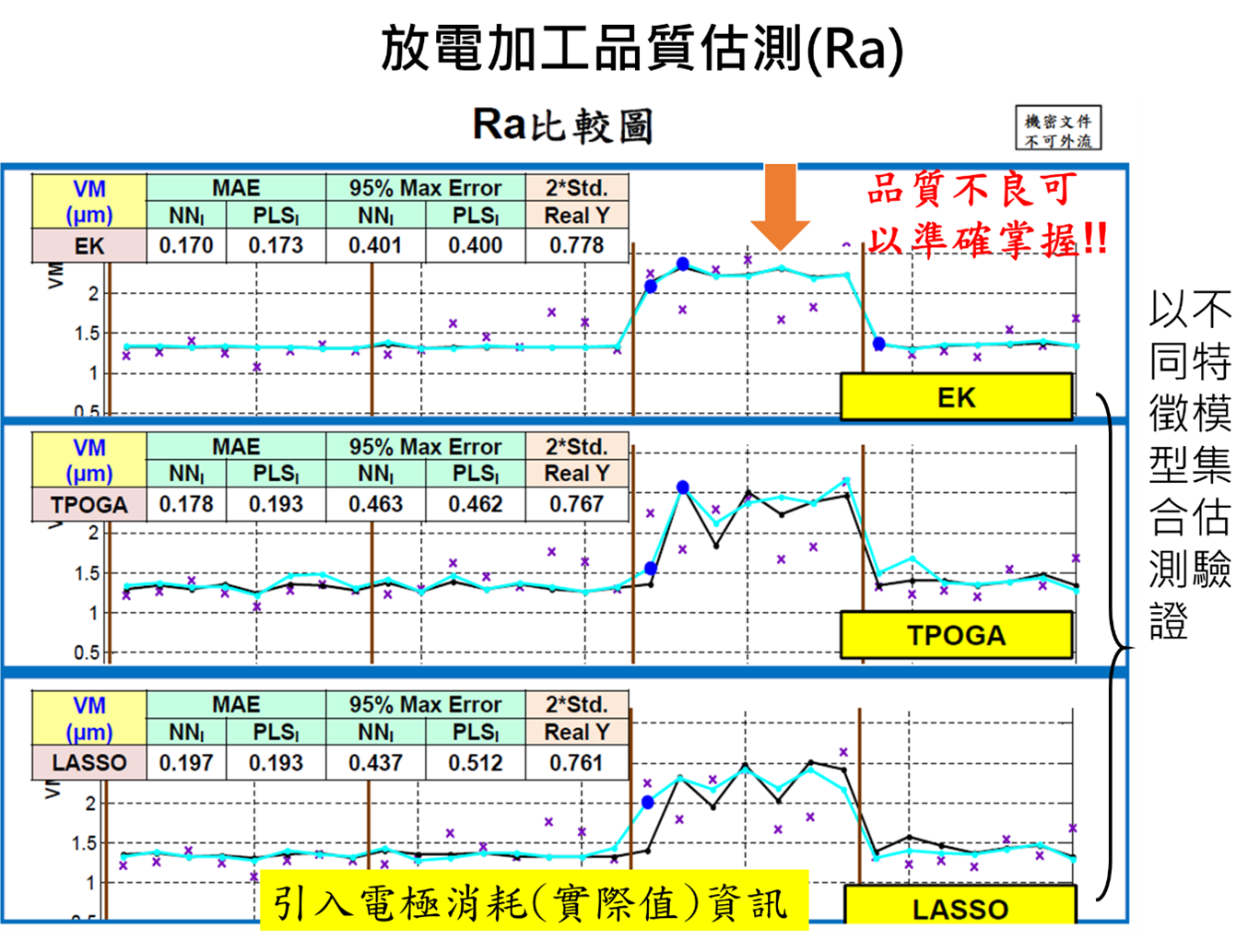

This study performs high-frequency signal collection of voltage and current for EDM equipment. Combined with dimensional measurements, 200 sets of production sensor data were collected. By organizing data chronologically, a t-SNE model was completed to identify seven features corresponding to machining quality (e.g., spark frequency, gap voltage, peak current). Subsequently, a BPNN (Back Propagation Neural Network) model was established to predict machining quality, with an average response time of 7–8 seconds, providing early warnings for process anomalies.

Data Collection and Feature Extraction

Data Collection Phase:

When the sensor module initiates a collection command, it periodically polls the equipment status. During the machining process, sensors capture data including Open Voltage, Gap Voltage, Peak Current, Pulse Duration Time, and Pulse Off Time. Feature characteristics of the sensor signals are calculated and correlated with machining precision to extract key features for precision prediction.

|

Feature Modeling Phase: Typical EDM precision is defined by dimensional accuracy and surface roughness. Profile accuracy is determined by the electrode, discharge current, and discharge time, while surface roughness is influenced by current, time, and material properties. During finishing, the interaction between the electrode and workpiece, parameters, and debris removal affects quality. Based on electro-thermal model theory and workpiece characteristics, factors such as Open Voltage, Gap Voltage, Peak Current, Pulse Duration, and Pulse Off Time are combined with actual pulse size and count to predict EDM precision.

The implementation of this technology integrates online monitoring modules (voltage/current sensing) with image-based electrode wear analysis. Through key feature extraction and a self-developed algorithmic framework, it correlates offline tolerance measurements with feature values to quickly identify the relationship between electrode wear and specific features. By using a segmented measurement approach at each stage, real-time electrode wear data is fed back to refine the predictive model. Multiple calibrations effectively enhance the stability of the precision prediction system. An intelligent AI compensation model was established using area estimation and current self-modulation to generate input/output relationships. By estimating the effective contact area, the equipment parameters can be precisely controlled, managing electrode tip wear to maintain precise features.

|

Industrial Benefits: From Aerospace to Electric Vehicle (EV) Applications

In a rapidly changing industrial environment, MIRDC continues to invest in the R&D of metal materials and process technologies, actively integrating AI tools to enhance the competitiveness of Taiwan's manufacturing sector. These applications extend to medical devices, energy, and aerospace, responding to Net-Zero and sustainability trends. The "Aerospace AI-Optimized EDM Technology" successfully breaks through the bottleneck of relying on manual experience. Real-world implementation shows that finishing time can be reduced by over 50%, with precision stabilized within 5 μm. This reduces electrode loss, improves yield, and strengthens the autonomy of the domestic aerospace supply chain, reducing reliance on foreign high-end equipment.

Currently, MIRDC has technical collaborations or service contracts with over ten companies, including Shingshen, First EDM, Joemars, and Ingeary. This has been successfully applied to domestic high-end EV connector terminal mold lines and helped First EDM establish intelligent functions for high-end machines used by international aerospace giants. This technology has successfully pushed traditional EDM into the era of smart manufacturing and will further expand into new energy vehicles, aviation, space, and medical fields.

Future Outlook: Toward a New Milestone in Smart Manufacturing

Looking ahead, MIRDC will continue to deepen the intelligent integration of AI with critical processes such as EDM and ECM. We aim to develop higher-precision virtual sensing and process prediction models to achieve full-process intelligent compensation, supporting the high-efficiency machining of large, complex aerospace components. Meanwhile, we will establish cross-factory and cross-border process logs and remote monitoring capabilities to strengthen supply chain responsiveness and data value, pushing Taiwan’s precision manufacturing toward a new milestone of intelligence and international alignment.