Edge-Cloud Engine Technology and Cross-Location Information Integration Application

Amid global economic instability, the Russia-Ukraine conflict, and the ongoing US-China trade war, the restructuring of the supply chain presents both new challenges and opportunities for the rubber and plastics industry. Taiwanese manufacturers must strengthen their global presence, focus on R&D for high-value-added circular materials, and enhance competitiveness. Driven by the electrification of automobiles, as well as growth in packaging and manufacturing, the global output value of the rubber and plastics industry reached $25,582 million in 2023 and is projected to grow by 6.7% in 2024. In response to these changes, Taiwanese companies are actively expanding into Southeast Asian and European markets, and are adopting Industry 4.0 technologies to reshape their value chains. Against this backdrop, assisting domestic blow molding equipment manufacturers with digital transformation by introducing a machine-to-machine (M2M) connectivity and utilization visibility system, alongside an Edge-Cloud Engine Platform, effectively achieves cross-location information integration and real-time monitoring, strengthening international competitiveness and market expansion potential.

Edge-Cloud Engine Platform Technology: Effortless Cross-Industry M2M Connectivity and Local Implementation

In the metal processing industry, M2M connectivity technology for brands like Fanuc, Mitsubishi, Siemens, Heidenhain, and Syntec is already quite mature. For instance, using VMX SMB (Shared Memory Block) allows the integration of various controllers into a single interface. Users can obtain specific machine data based on the Data Path, achieving a consistent method for data reading and processing across different brands.

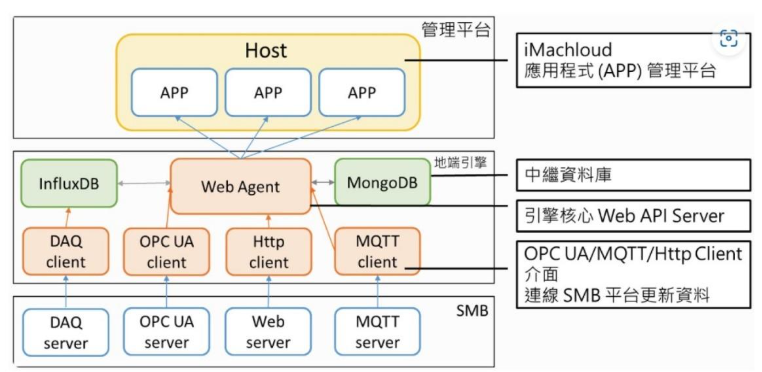

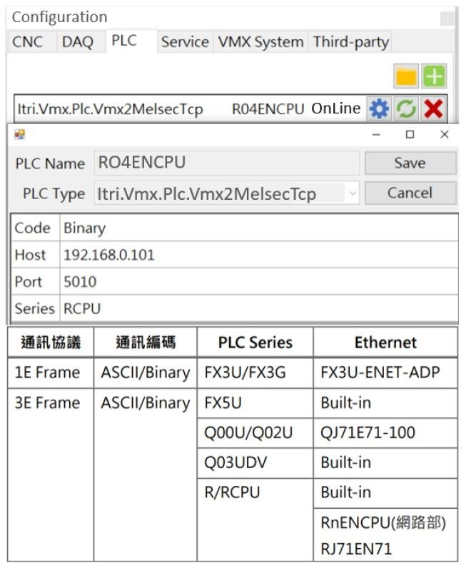

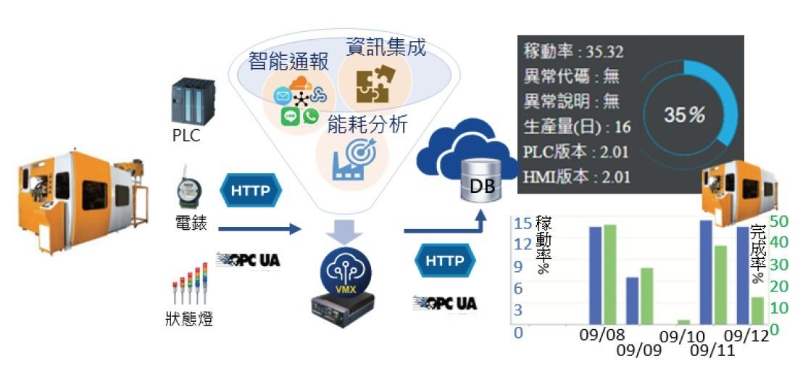

When applied to specialized machinery like blow molding machines, besides communicating with mainstream controllers, the PLC (Programmable Logic Controller) often serves as the core control unit, requiring information to be acquired through it. Industrial PLCs offer extensive Ethernet communication capabilities, such as TCP/IP and UDP protocols, supporting high-speed transmission and remote monitoring. Users can remotely read and write PLC data using these protocols. The Edge-Cloud Engine Platform provides three communication interfaces, allowing for API integration based on requirements to enable data access for information models in the rubber and plastics industry [1][2]. Currently, the Edge-Cloud Engine Platform integrates multiple SMBs and supports connectivity with PLC communication modules such as Mitsubishi MELSEC, Siemens S7, and Modbus, facilitating data processing and application development for different PLCs. Whether for general-purpose or specialized machines, data can be efficiently integrated via SMBs, making it an ideal platform for unified data management in diverse controller environments.

|

In terms of machine information integration, the PLC is responsible for monitoring and recording machine operational information and related alarm messages. It also integrates data from various peripheral sensors, including temperature, pressure, limit switches, and electric meters. This sensor data is typically time-series information, and using a DAQ client helps meet the requirement for higher-speed transmission, thereby achieving comprehensive monitoring and data collection for the entire machine system. This allows us to obtain complete machine operational information for subsequent visualization in SCADA (Supervisory Control and Data Acquisition) systems, enabling operators to intuitively monitor and analyze machine status.

In the concrete implementation process, an application named "UTDC Automatic Data Collection Service" is developed on the Edge-Cloud Engine Platform. This application connects to the PLC communication module via SMB, establishing a data connection with the target device. This application automatically reads information within the PLC and writes this data to the corresponding fields in the database based on pre-defined mapping relationships, as shown in Figure 2. In this process, establishing a detailed mapping table is crucial. This table describes how the information read by the PLC is mapped to the database and specifies the steps for batch processing. These specifications include parameters such as PLC address, data type (e.g., Bit, Word, DWord), decimal places, data table name, data field name, access mode (Read/Write), update mode (Insert/Update), and update condition (Period/Change). These configurations ensure consistency throughout the data transmission process and make subsequent data management and processing more efficient.

|

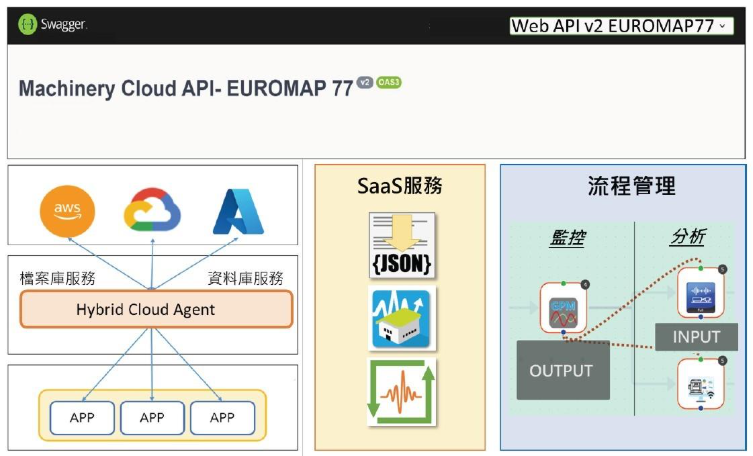

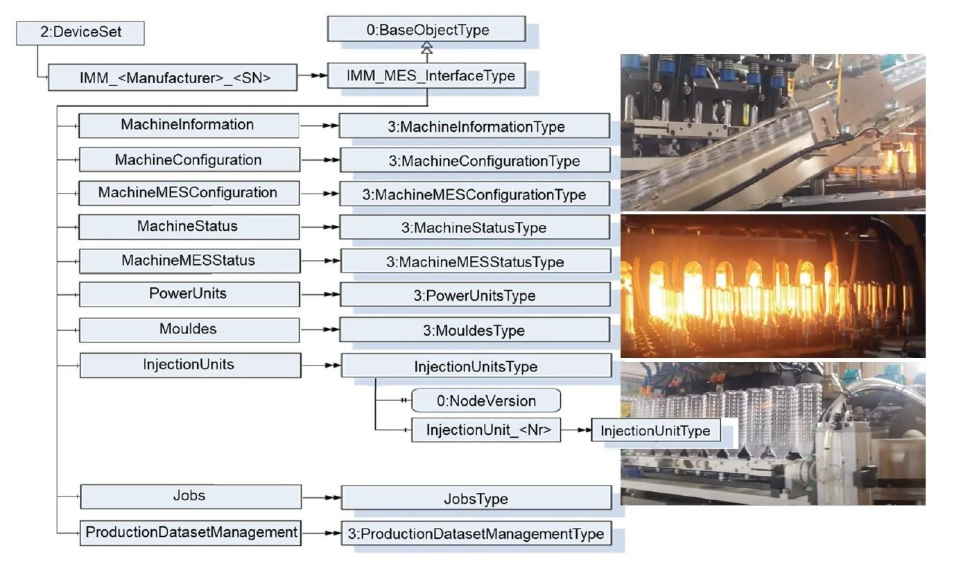

The Server APP, based on the OPC UA protocol, aims to efficiently collect and centrally manage machine operation information through the SMB's PLC communication module. The Edge-Cloud Engine is primarily built upon the OPC UA communication framework, establishing a data model by referencing common information object specifications for plastics and rubber equipment defined in EUROMAP 77, 82.1, 82.2, 82.3, etc. This model covers key data elements such as machine basic information, equipment configuration, injection unit, mold, and drive system. This data is standardized into a unified structure, allowing for consistent and seamless data exchange and integrated management across different brands and models of equipment, enhancing the system's operability and flexibility.

In addition to the standardized data model, the system can also support the simultaneous uploading of multi-machine information to the cloud platform via the Edge-Cloud Engine, as shown in Figure 3. Based on the equipment list set in the Edge-Cloud Engine Manager, the system can automatically adjust the number of connected machines, ensuring devices are dynamically added or removed according to demand, flexibly responding to different production scales. To ensure data immediacy, the application automatically updates information regularly, guaranteeing that the OPC UA Client program can obtain the latest machine status and operational messages. Users can develop their own OPC UA Client applications or use existing OPC UA Client tools to connect and manage data for further access and analysis, enabling direct data monitoring and analysis without additional development. This flexible and scalable design not only meets data integration needs across different equipment but also provides powerful support for subsequent data applications.

|

Cross-Regional Information Integration Application

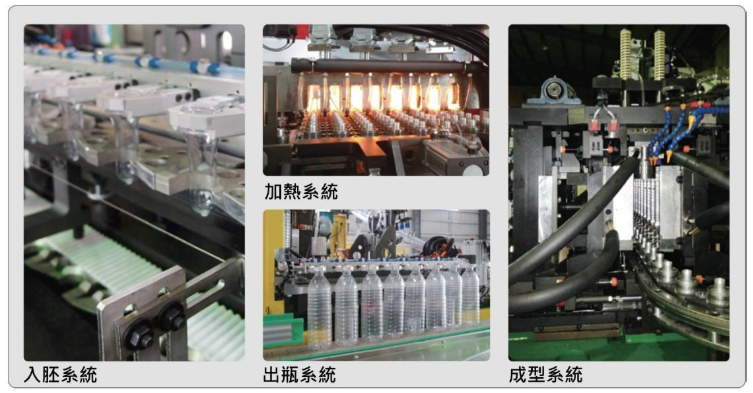

A domestic blow molding equipment manufacturer divides its automated manufacturing process into five system items, as shown in Figure 4: (1) Preform Feeding System transports preforms from the hopper to the unscrambler via a conveyor belt, then automatically arranges them in sequence for single-lane feeding; (2) Rotary System transports the preforms on the single lane to the heating system; (3) Heating System batch-heats the preforms to the target crystallization temperature; (4) Molding System sends the heated preforms to the mold, performs clamping, and executes blow molding; (5) Bottle Output System transports the finished bottles out for connection with downstream process equipment.

|

The aforementioned systems typically use common analog I/O, physical analog knobs, and pointer/LED meters, which are not conducive to digital transformation. Therefore, the Edge-Cloud Engine is utilized to introduce ICT (Information and Communication Technology) resources, as shown in Figure 5, facilitating the subsequent development of intelligent value-added modules and production line operation service platforms to address these improvement needs. Examples include digitalized HMI to reduce difficulty in machine adjustment and maintenance costs; an online operation monitoring system to check temperature, pressure, limit switches, electric meters, etc., ensuring correct execution. If issues occur, in addition to the on-site three-color light alarm, an active notification system informs the manufacturer and client simultaneously, ensuring timely resolution of issues to minimize impact on mass production. The establishment of an utilization rate visualization system is expected to provide real-time utilization and OEE, implementing site transparency and enhancing the speed of decision evaluation response. This then extends to multi-equipment and cross-regional integration to strengthen the blow molding equipment manufacturer's automated blow molding line services, creating a Blow Molding Line Operation Service Platform, as shown in Figure 6.

|

|

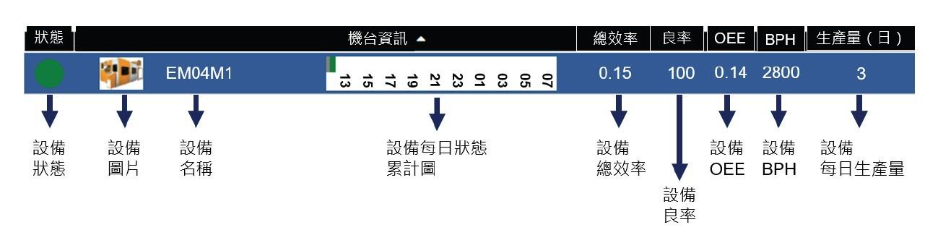

The utilization rate visualization system is designed to provide a real-time and comprehensive production monitoring platform, integrating data visualization, historical data analysis, and anomaly warning functions, helping companies efficiently manage production operations. Core functions include real-time monitoring of equipment status, visualized presentation of production data, and historical record analysis. Users can view key indicators for each piece of equipment, such as utilization rate, runtime, and downtime reasons, through the website dashboard. This data is displayed in charts for quick grasp of the situation and issues. The system supports multi-level user permission management, where operators, managers, and maintenance personnel receive different data access and operation permissions according to their roles, ensuring data security and improving efficiency.

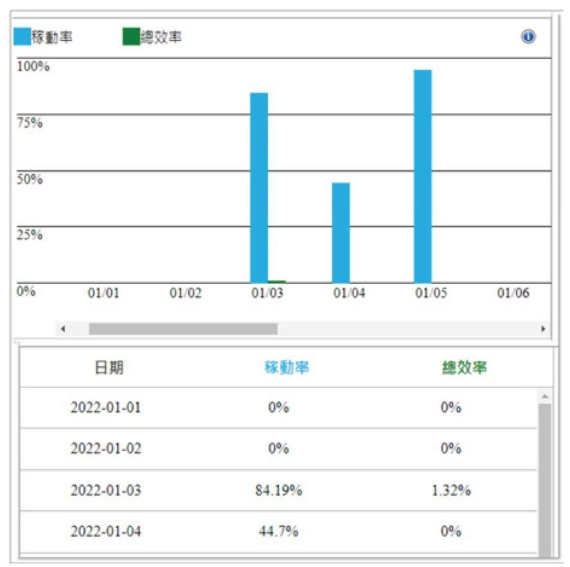

In the Overall Plant View interface, important indicators such as Overall Equipment Effectiveness (OEE), Bottles Per Hour (BPH), and daily output are customized for display, allowing managers to instantly grasp the overall plant situation. Clicking on a single machine icon provides detailed information, including PLC and HMI versions, and preform parameters, assisting technical personnel in judging the machine's running status. Upon entering the Machine History screen, as shown in Figures 7 and 8, the system displays daily operating hours and statistical data in charts, including utilization rate and OEE, helping to identify performance bottlenecks and anomalies. This historical data analysis contributes to optimizing scheduling and equipment strategies, effectively boosting overall production efficiency.

|

|

In the production environment, a Host Notification Mechanism with real-time response and centralized management capabilities can significantly enhance production efficiency and safety. When equipment fails or an anomaly occurs, the system can instantly send an alarm, helping operators and maintenance personnel quickly resolve the issue, reducing downtime and accident risks. This mechanism supports remote monitoring, allowing managers to receive real-time information and intervene even when not on-site. Furthermore, the system has automated processing capabilities to send failure reports and initiate maintenance procedures, improving processing efficiency and accuracy, and retaining detailed records for subsequent analysis and improvement, increasing production transparency and maintenance effectiveness. Common notification methods are LINE Message and Email. LINE offers immediacy and interactivity, allowing for rapid notification pushing, suitable for daily operations requiring immediate response. While Email is less immediate, it is more suitable for transmitting formal, structured content, supports attached reports and long-term archiving, and is ideal for record keeping and formal reporting. Therefore, the appropriate notification mechanism should be selected based on actual needs.

Additionally, the system provides a Web API interface, enhancing data access and application integration capabilities. External applications such as MES, ERP, or other automation systems can quickly access real-time and historical data through standardized APIs for analysis, visualization, or report generation, as shown in Figure 9. Managers can query equipment utilization rate, runtime, and downtime reasons, while technical personnel can grasp fault and parameter information for preventive maintenance. The API supports formats like JSON, making data transmission lightweight and easy to parse, improving system flexibility and expandability.

|

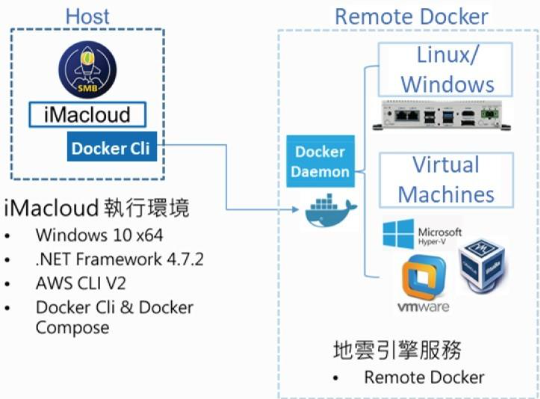

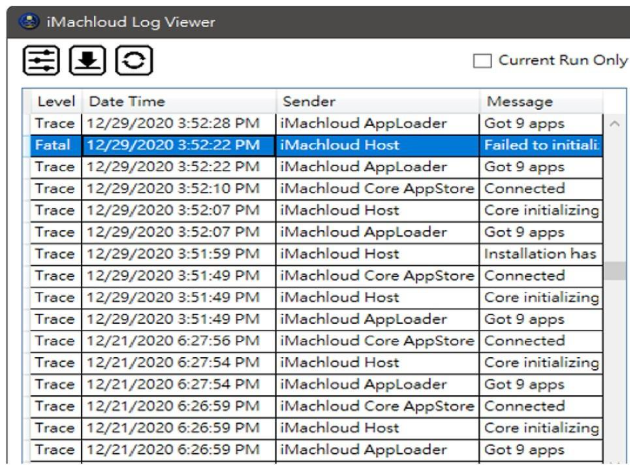

Beyond the above, the Edge-Cloud Engine uses Remote Docker services managed by the Edge-Cloud Engine Manager to meet demands for remote deployment and on-site maintenance. Equipment manufacturers can also use the first-hand information from the Edge-Cloud Engine to remotely help clients quickly pinpoint problems, significantly reducing spatial constraints and time costs, as shown in Figures 10 and 11.

|

|

By leveraging the Edge-Cloud Engine technology provided by the Smart Machinery Cloud Standard RUNTIME, the reach of applications developed by Taiwanese developers with domain knowledge can be expanded, making it easier to overcome the barriers of proprietary systems. This offers more diverse choices and rapid application adoption for more Taiwanese manufacturing plants and end-users, completing digital transformation. Standard communication also enables companies to quickly utilize applications and flexibly apply them to industry needs, rapidly expanding the industry's benefits and scale in target markets, and elevating the system to an internationally competitive standard version. Furthermore, the common application software development tools provided within the Standard RUNTIME environment assist the machinery industry in possessing independent cloud service technology, guiding companies to develop application services, and transforming the industry into a provider of manufacturing, system integration, and software service TURNKEY solutions.

References

[1] “OPC UA for Plastics and Rubber Machinery,” OPC, July 2020. [2] “OPC UA interfaces for plastics and rubber machinery–Data exchange between injection moulding machines and robots,” EUROMAP Technical, 2021.