Virtual Machine Tool Digital Twin Platform

Industrial Technology Research Institute (ITRI), Smart Machinery Technology Center, Smart Manufacturing Technology Group, Smart Manufacturing Trial Operation Department

Jian-Yi Li (R&D Manager), Chia-Chin Chuang, Shan-Jen Yang, Shang-Chun Lin (Associate Engineers), Shao-Ku Huang (Manager)

According to an IoT ANALYTICS survey, 29% of global manufacturers have implemented digital twin technology. IT vendors such as AWS accelerate industrial adoption through IoT TwinMaker, while SIEMENS offers digital twin solutions via its Xcelerator platform. However, major international controller manufacturers (e.g., FANUC and SIEMENS) provide digital twin platforms that are limited to proprietary controllers. Although virtual control kernels enable simulation, they lack machine structural characteristics, making it difficult to improve motion accuracy prediction.

The Virtual Machine Tool Digital Twin Platform integrates CNC simulators, servo drive systems, kinematics, and structural dynamics models. It supports five-axis machine simulation and spindle thermal compensation, reducing motion debugging time while maintaining thermal compensation accuracy.

Five-Axis Virtual Machine Tool Digital Twin Platform

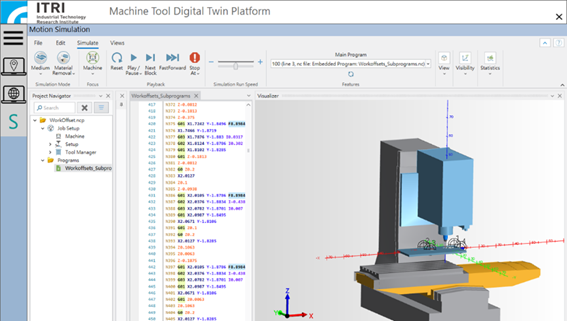

This platform combines multi-axis virtual machine configurations with commercial CNC simulators. By introducing digital twin technology before multi-axis machining, it enables virtual debugging and quality simulation prior to product development and trial cutting. This reduces machine interference and prevents programming errors that could cause collisions or poor machining quality.

The platform offers modules such as:

- Virtual machine tool configuration

- CNC simulator

- Collision and interference check

- Mechatronics integration

- AI-based spindle thermal displacement prediction and compensation

It supports custom communication protocols for commercial controllers (including PC-based controllers) and complies with Industry 4.0 standards like OPC UA for hardware-in-the-loop synchronization. CNC programs and machine coordinates can be read from virtual or real controllers and imported into the five-axis kinematic model, enabling full machine testing and machining simulation on the platform.

|

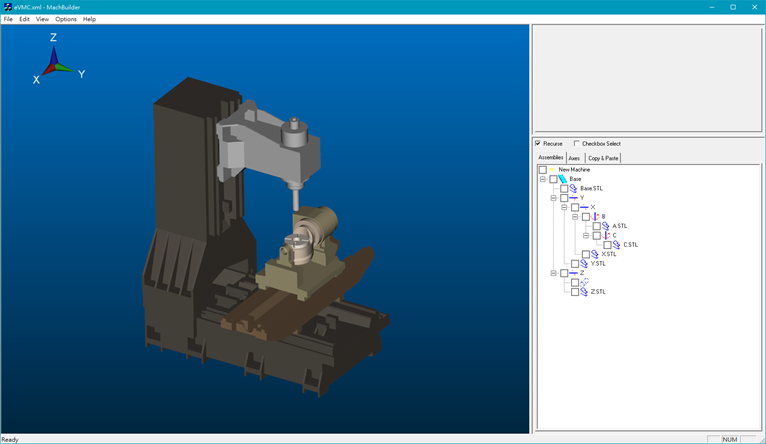

Virtual Machine Tool Configuration Module

To visualize five-axis machining, this module displays different machine configurations using 3D models built from STL files. The motion chain includes components such as columns, spindle heads, bases, tables, and linear guide saddles. Motion chain design considers relationships between axes, machining range, tool orientation, tool type (end mill, ball end), workpiece position, material type, axis origins, and motion type (linear or rotary).

|

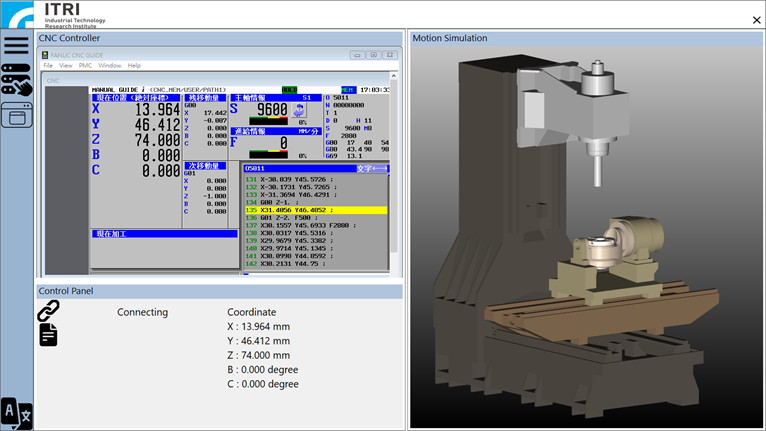

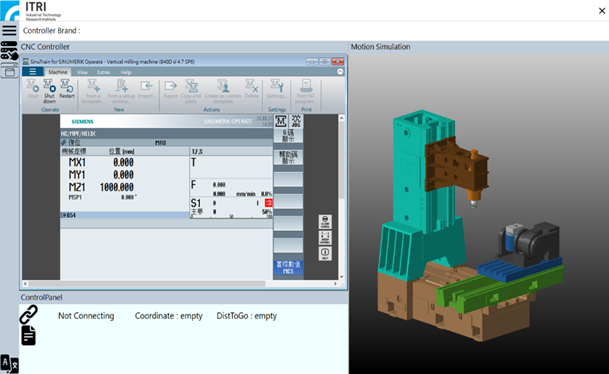

CNC Simulator Module

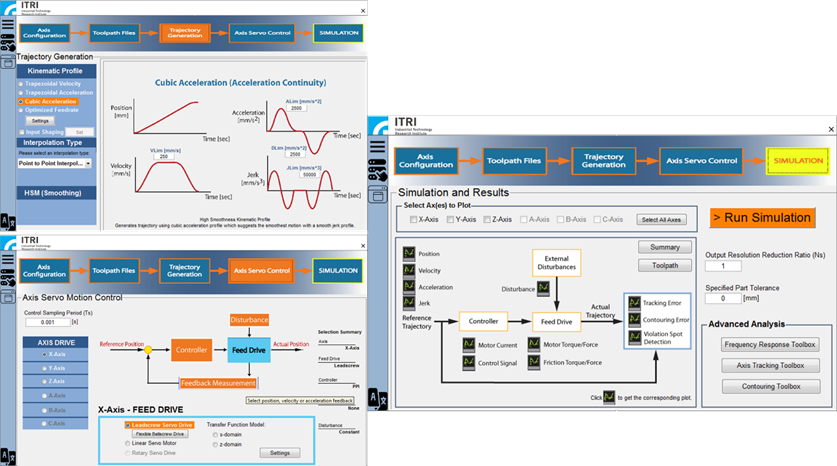

ITRI developed a CNC kernel digital twin module that includes:

- Motion generation unit (point-to-point and curve settings for position, speed, acceleration, jerk)

- Servo control unit (rigid-body dynamics and multiple control strategies such as PID, lead-lag, zero-phase error tracking, sliding mode control)

- Analysis unit (frequency response, axis tracking, contour error)

Unlike existing systems tied to specific brands (FANUC, SIEMENS), this module supports multi-brand CNC simulators and real controllers, integrating with commercial tools like FANUC NCGuide and SIEMENS SinuTrain.

|

|

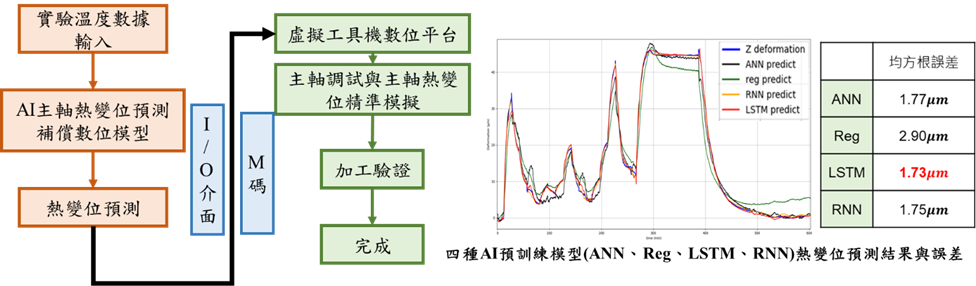

AI Spindle Thermal Displacement Prediction Module

Thermal displacement accounts for 40–70% of machining errors. The platform uses AI models to predict spindle thermal displacement based on temperature sensor data and operating conditions. Compensation values are transmitted via I/O interfaces to CNC simulators.

|

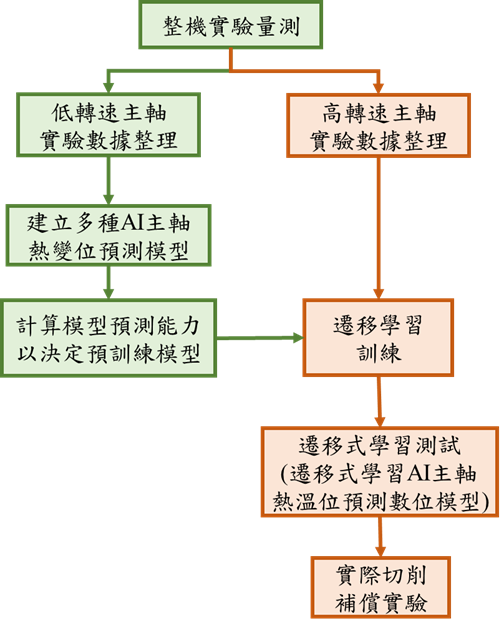

To reduce retraining time when changing spindle speeds, transfer learning is applied:

- Collect experimental data for different speeds

- Build multiple AI models (ANN, CNN, RNN, LSTM)

- Train and test transfer learning models

- Validate compensation through actual cutting tests

|

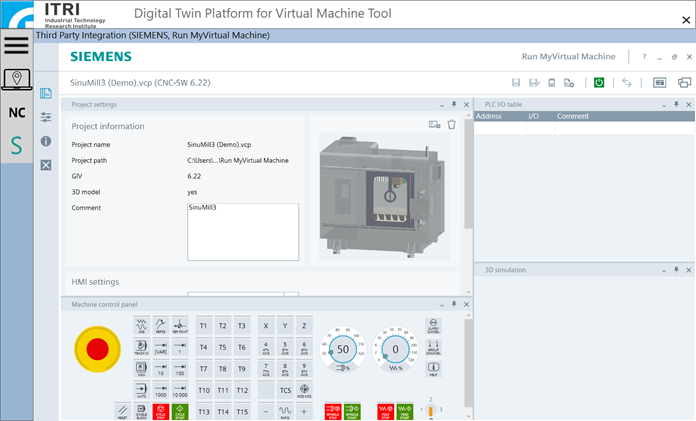

Third-Party Software Integration

The platform integrates SIEMENS Run MyVirtual Machine (RMVM) for virtual machine development, machining simulation, and quality prediction. It also supports ModuleWorks for 3D simulation, including cutting and machine motion, and NcEditor for CNC program-based simulation.

|

|

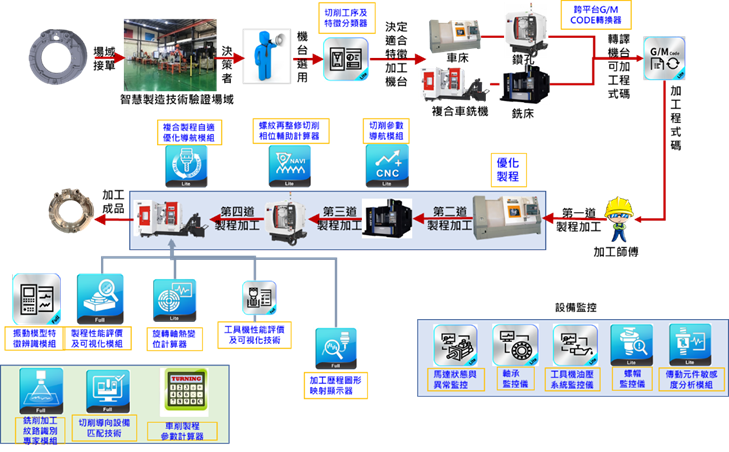

Validation in Smart Manufacturing Testbed

Digital twin models were validated on four metal-cutting machines (turning center, drilling/tapping machine, milling center, and turn-mill machine). Cross-platform data exchange, cloud deployment, and standardized controller communication were implemented, along with 18 SaaS applications for smart services.

|

Conclusion

ITRI developed a domestic machine tool digital twin platform that supports virtual CNC programming, machine configuration, cutting force simulation, collision detection, spindle thermal compensation, CNC simulation, structural dynamics, and transmission system modeling. It helps manufacturers provide machining time estimates before order acceptance, accelerates on-site debugging, and integrates commercial controllers and third-party software to expand the machine tool ecosystem and drive Taiwan’s digital transformation.

Acknowledgment

Thanks to the Ministry of Economic Affairs Industrial Development Bureau for supporting the project “Smart Equipment and System Cloud Value-Added Service Technology Development – Equipment Intelligence and System Integration Application Verification (P353CH2310).”

References

- Li Jian-Yi, Chuang Chia-Chin, Huang Shao-Ku, “Virtual Machine Tool Digital Twin Platform,” Machinery Industry Magazine, Issue 488, pp. 12–18, 2023.

- Li Jian-Yi, Wu Po-Hsun, Huang Shao-Ku, Lo Tso-Liang, “Green Smart Manufacturing Technology for Machine Tools,” Machine Tools and Components Magazine, Issue 144, pp. 62–66, 2022.

- MachineWorks – https://www.machineworks.com/

- FANUC CNC Guide – https://www.fanucamerica.com/products/cnc/cnc-software/programming-simulation-software/cnc-guide-simulation-software

- SIEMENS SinuTrain – https://xcelerator.siemens.com/global/en/industries/machinebuilding/machine-tools/cnc4you/sinutrain-uebersicht.html

- Z. Zhang et al., “Geometric error measuring, modeling, and compensation for CNC machine tools: A review,” Chinese Journal of Aeronautics, 37(2), pp. 163–198, 2024.

- SIEMENS Run MyVirtual Machine – https://www.siemens.com/global/en/markets/machinebuilding/machine-tools/cnc4you/fokus-digitalisierung/run-myvirtual-machine.html

- ModuleWorks – https://www.moduleworks.com/