EMO 2025 | 50th Anniversary: Spotlight on Digital Twins × Flexible Automation × AI Assistants

Preface

The EMO 2025 European Machine Tool Exhibition was held in Hannover, Germany, from September 22 to 26. The five-day event showcased advanced machine tool manufacturing technologies. The first EMO exhibition took place in Paris in 1975, co-organized by the European Association of the Machine Tool Industries and the German Machine Tool Builders’ Association. Since then, the show has expanded steadily under a biennial rotation among Germany, France, and later Italy, growing into one of the world’s most prominent machine tool technology exhibitions.

This year marks the 50th anniversary of EMO. In addition to reviewing five decades of industry evolution, the exhibition also outlined key development pillars for the future of machine tools and manufacturing: Innovative Manufacturing, emphasizing three major themes—automation, sustainability, and digitalization. Compared with the 2023 edition, the 2025 show was slightly smaller, with exhibition halls reduced from fifteen to thirteen and total visitors reaching around 80,000. Taiwan ranked as the fourth-largest exhibiting nation, with 121 participating companies.

This article highlights key observations related to automation, digitalization, and AI-enabled manufacturing, offering insights for future industrial development.

1. Flexible Automation Systems

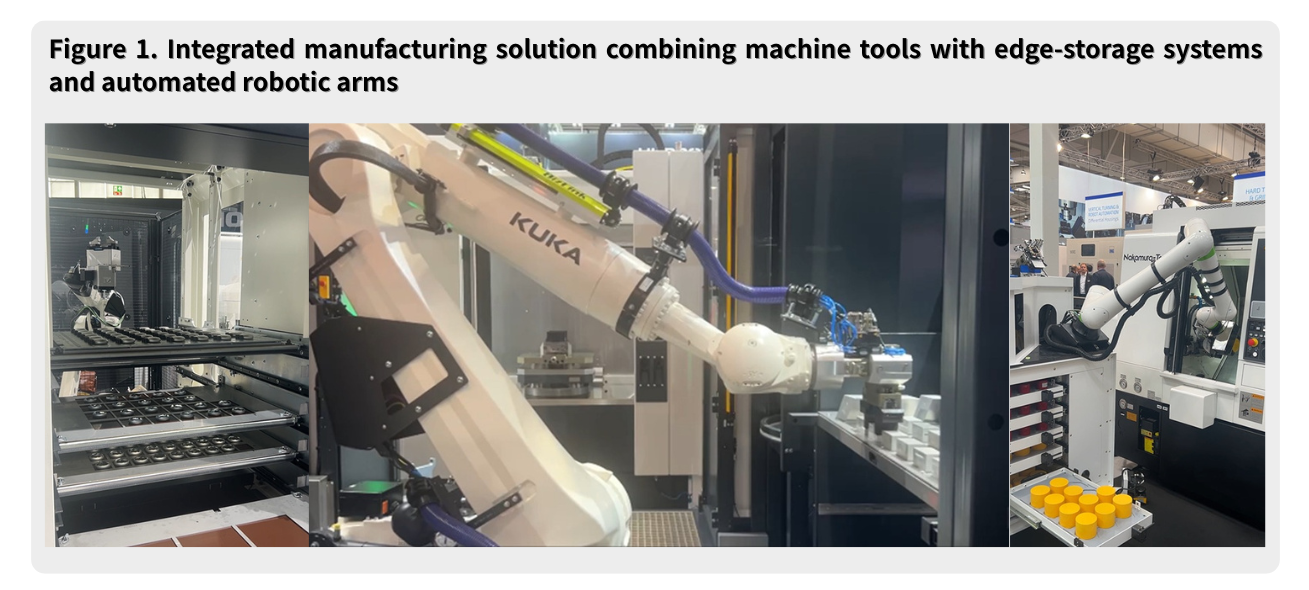

In recent years, European manufacturers have also faced growing labor shortages. As a response, flexible automation has emerged as a crucial strategy for machine tool builders. At the show, DMG MORI demonstrated automation solutions tailored to various industries—including aerospace, semiconductors, automotive, biomedical, energy, and precision components. By integrating machine tools with edge-storage systems and robotic arms, the company showcased modular production cells capable of flexible loading/unloading and automated jig/fixture changeovers.

Unlike traditional full-line automation, these smaller modular cells offer greater adaptability and support seamless human–machine collaboration. The line-side storage systems can accommodate fixtures, raw materials, robotic grippers, and more—extending unmanned operation time and reducing manpower demands.

Other machine tool builders, such as HELLER and MAZAK, as well as manufacturing system integrators, also presented flexible automation solutions, underscoring this trend as a central theme of EMO 2025.

For the "Factory of the Future," DMG MORI showcased various Autonomous Guided Vehicles (AGVs) and mobile robots capable of transporting materials, chip bins, large components, and tools. Driven by a Smart Manufacturing Execution System (MES), these systems coordinate production scheduling, tool management, and vehicle dispatching. Robots mounted on AGVs can move between machines, using CCD vision for origin positioning and workpiece alignment, enabling truly flexible "high-mix" production.

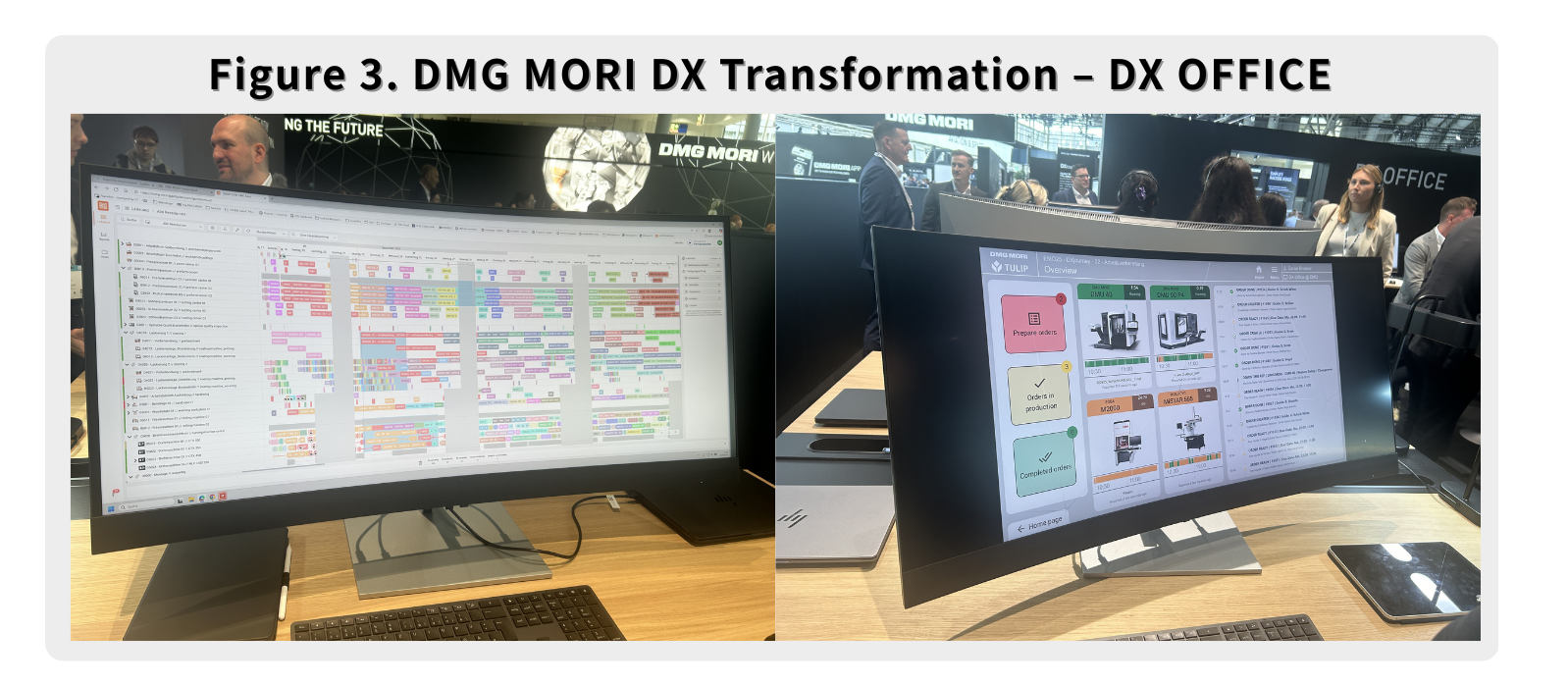

All scheduling is managed via DMG MORI’s DX Office, a digital process chain spanning from design to finished part. This ecosystem integrates software for MES & GenAI, NC Simulation, Digital Twins, and Tool Management. Notably, their GenAI provides real-time updates on order progress and equipment utilization.

2. Digital Transformation: Digital Twins and Control Technology

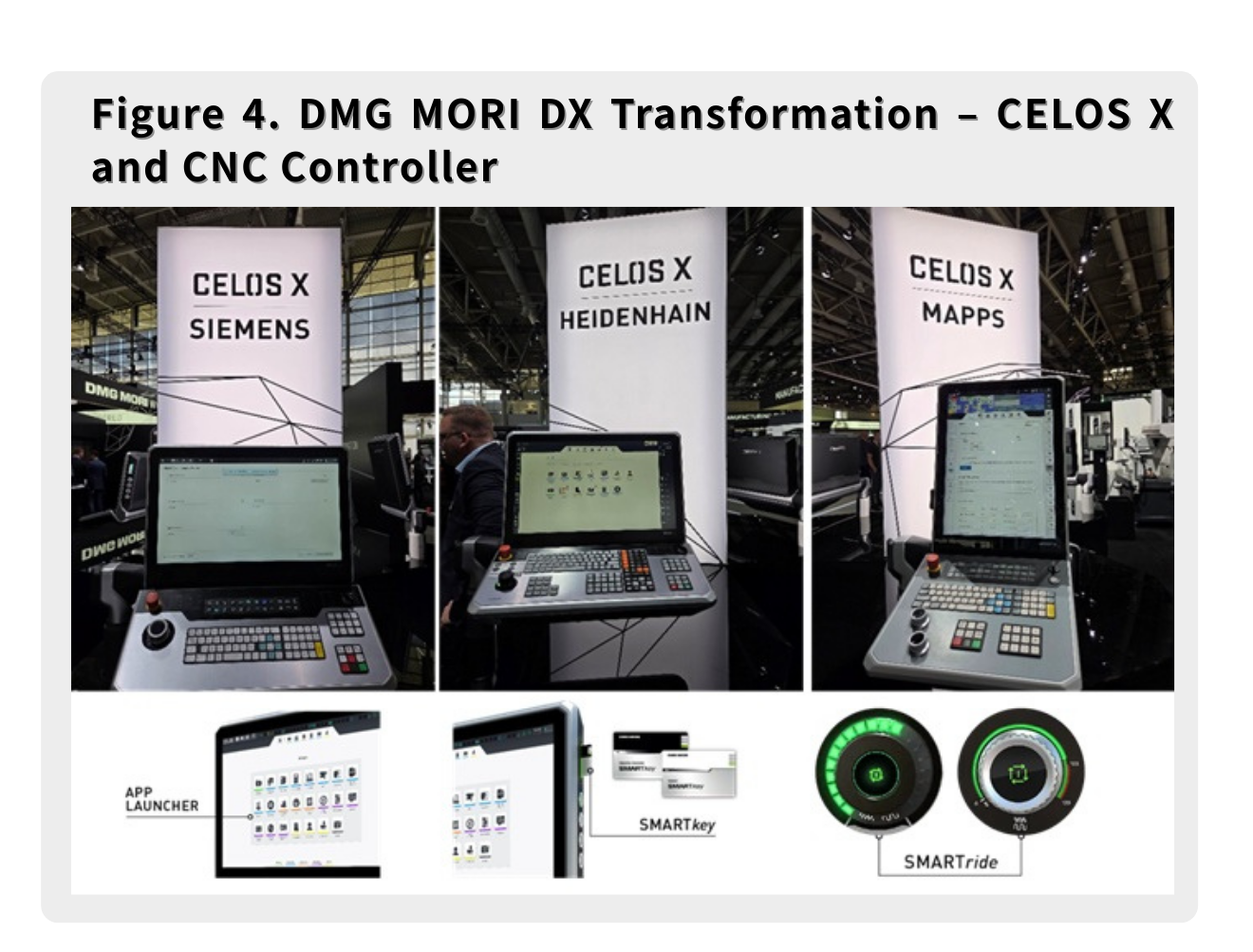

Under the theme "Manufacturing the Future," DMG MORI introduced CELOS X, a cloud-based platform providing a secure, end-to-end data space.

-

CELOS Xperience: Direct user interaction with apps and software.

-

CELOS Xchange: The control hub managing data across the ecosystem.

-

This platform is CNC-independent, supporting standards like OPC UA and MTConnect, and integrates with Siemens, Heidenhain, and Fanuc systems to enable Industry 4.0 functionalities such as dynamic collision monitoring and remote diagnostics.

DN SOLUTIONS introduced a Collision Protection System (CPS) based on Digital Twin technology. Utilizing GibbsCAM or Siemens software, the system predicts and stops potential collisions before they occur, preventing downtime. They also demonstrated a "Process Digital Twin" for multitasking machines, allowing operators to verify programs in a virtual environment via Siemens RMVM, significantly reducing setup risks.

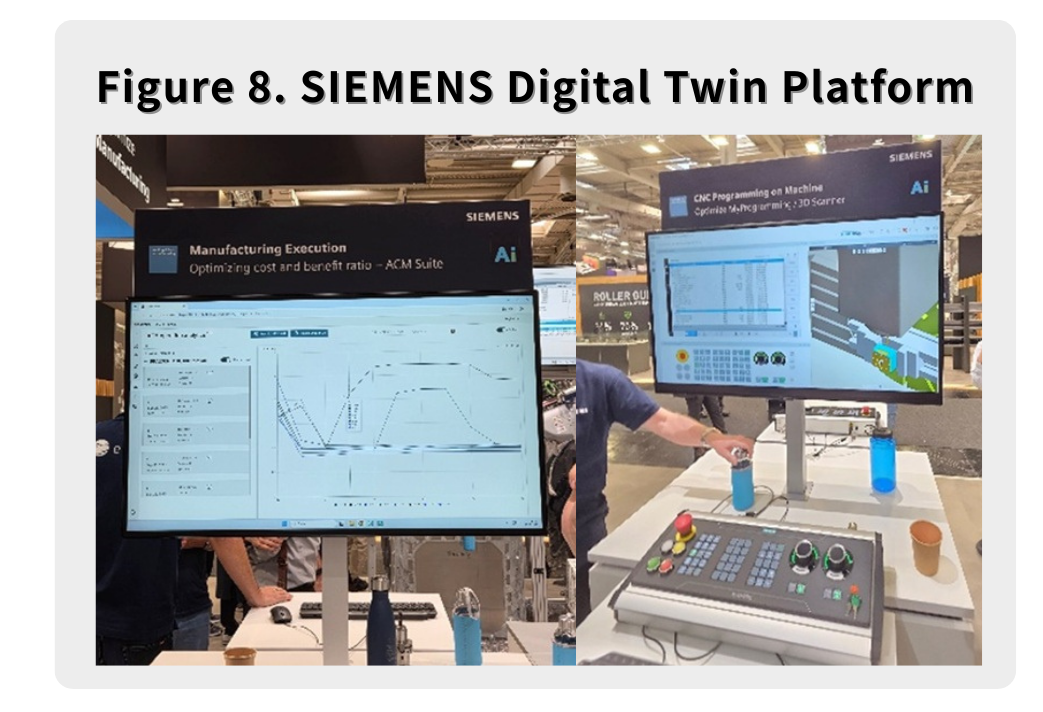

SIEMENS showcased their vision with the theme "Shape the Future of the Shopfloor. Now." Highlights included:

-

"Hubsi" (Unitree G1): A humanoid robot representing the future of flexible manufacturing.

-

SINUMERIK ONE: A digital-native CNC that enables 1:1 virtual machine simulation (Create My Virtual Machine), allowing users to optimize processes and train operators without risking physical equipment.

FANUC debuted the FS500i-A next-generation CNC, boasting 2.7x CPU performance and enhanced 5-axis capabilities. Their Smart Digital Twin offers three distinct advantages:

-

Motion Accuracy: Precise mechanical simulation via servo models to prevent collisions.

-

Cycle Time Prediction: Accurate estimation of processing times (up to 20x simulation speed).

-

Surface Quality Estimation: Digital inspection of surface finish without the need for physical trial cuts.

3. Artificial Intelligence: Smart Manufacturing Assistants

Generative AI (GenAI) was a major highlight of EMO 2025. Current applications focus on Human-AI interaction rather than fully autonomous results, where Large Language Models (LLMs) act as "Agents" to assist users.

-

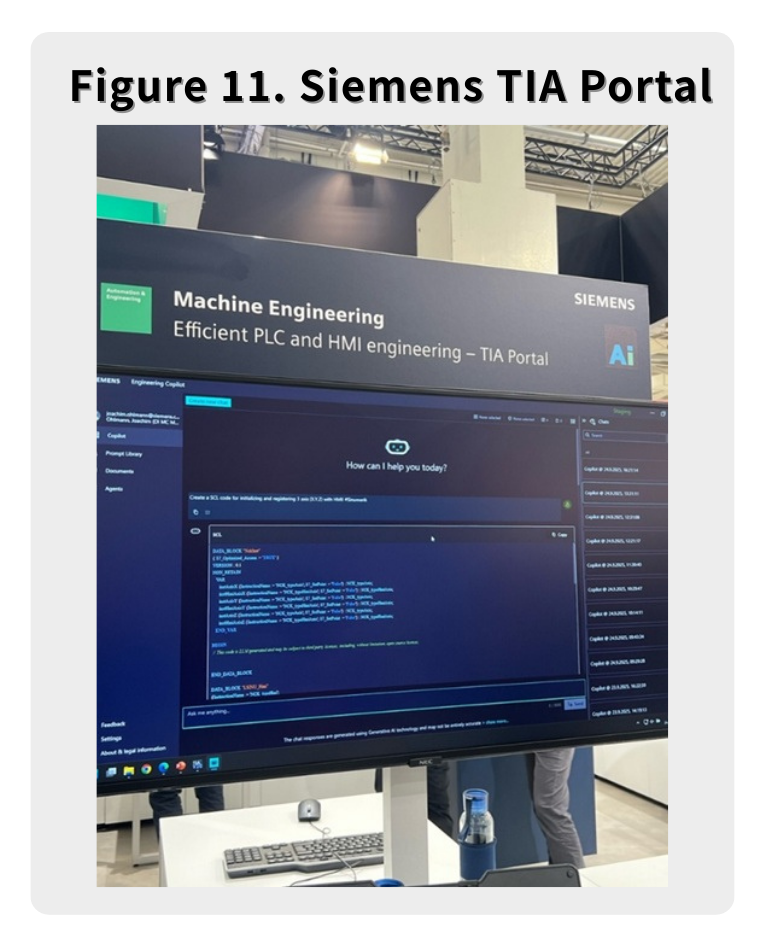

Siemens TIA Portal Copilot: Allows PLC programmers to describe logic in natural language; the AI then generates SCL (Structured Control Language) code.

-

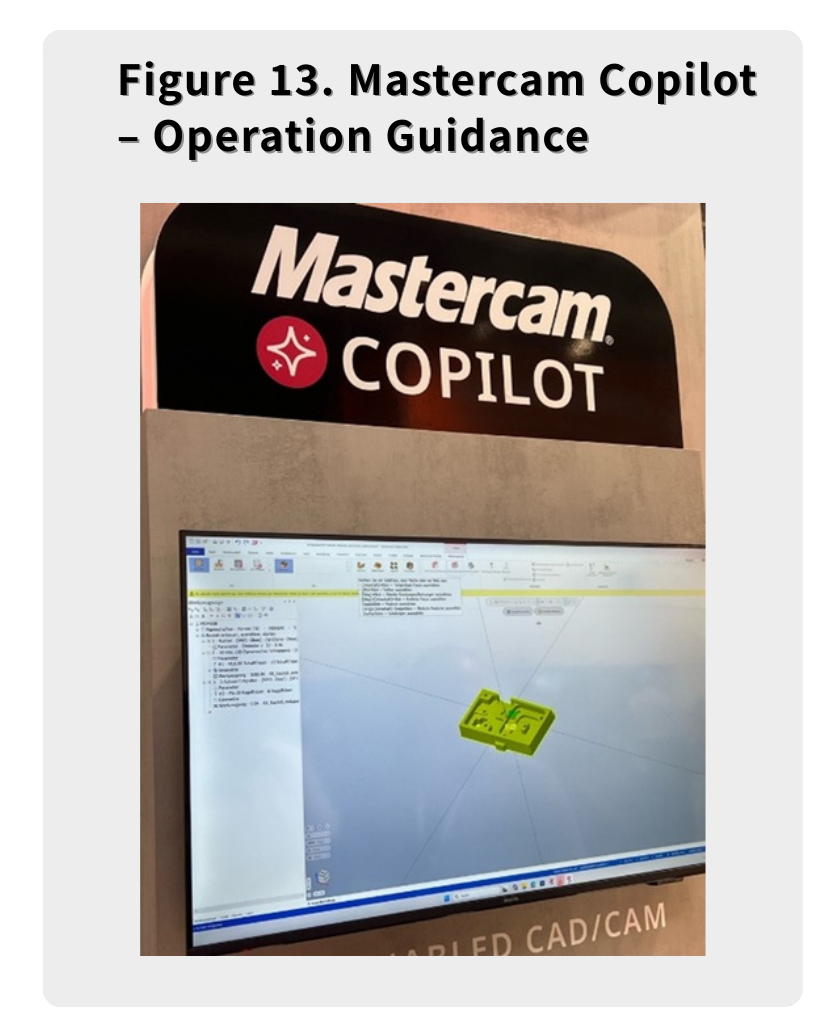

MasterCAM Copilot: Integrates the user manual with Microsoft Copilot, allowing beginners to ask questions in natural language, significantly shortening the learning curve.

-

Up2Parts CAM: Showcased automated project generation, recognizing features and tolerances from CAD files to decompose processing steps and estimate costs automatically.

.png)

4. Application of Emerging Materials

To achieve high precision and low-carbon manufacturing, manufacturers are moving beyond traditional cast iron. Mineral Casting and Ultra-High Performance Concrete (UHPC) structures were prominent.

-

DURCRETE exhibited a UHPC bed with a thermal expansion coefficient of only $6 \times 10^{-6}/K$, maintaining stability within $\pm 2\mu m$ even under temperature fluctuations. Its vibration damping is 10 times faster than cast iron.

-

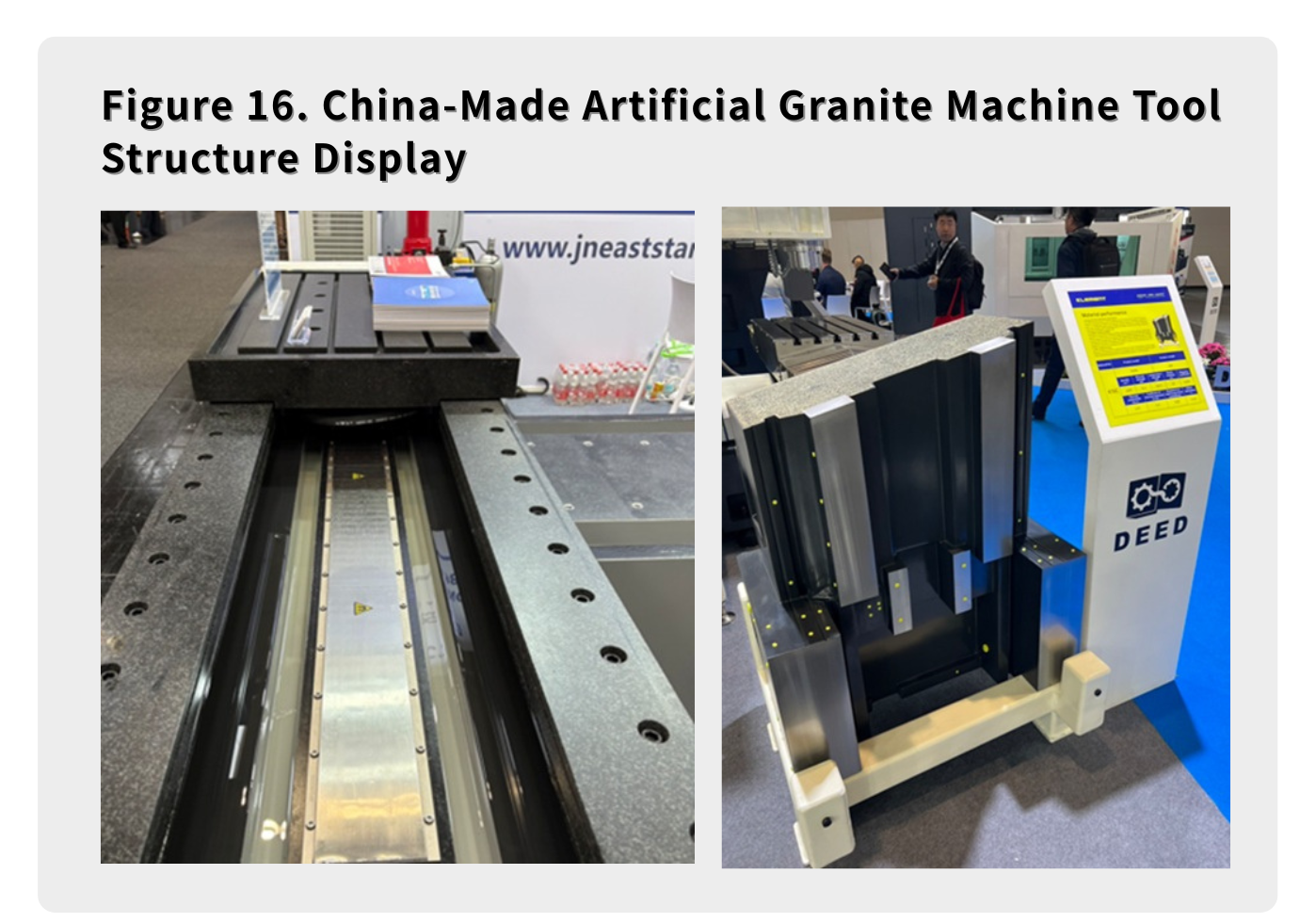

Chinese manufacturers (e.g., Claremont, Shandong Nano) also showcased polymer concrete beds that offer cost advantages while meeting ISO precision standards, gradually replacing mid-range metal structures.

-

Conclusion

The Taiwanese machine tool industry faces significant headwinds: the rise of low-cost Chinese competition, global trade wars, and a relatively strong currency compared to the depreciating Yen. As an industry primarily composed of SMEs, Taiwan must pivot toward high-end markets by integrating niche technologies and improving precision. The adoption of emerging materials (like mineral casting) offers a path to solving thermal-induced accuracy issues.

Furthermore, as the "Master Craftsmen" era fades due to labor shortages, AI is becoming the "digital brain" that inherits their expertise. While GenAI currently acts as a helpful assistant, the next stage is Embodied AI—AI with "hands and feet" that can drive production equipment as a professional engineer. Combining AI with immersive interactive tools will be the key to accelerating skill acquisition and diagnostic capabilities, ensuring Taiwan remains competitive on the global stage.