Intelligent Asia: A New Era of AI-Driven Smart Manufacturing Transformation

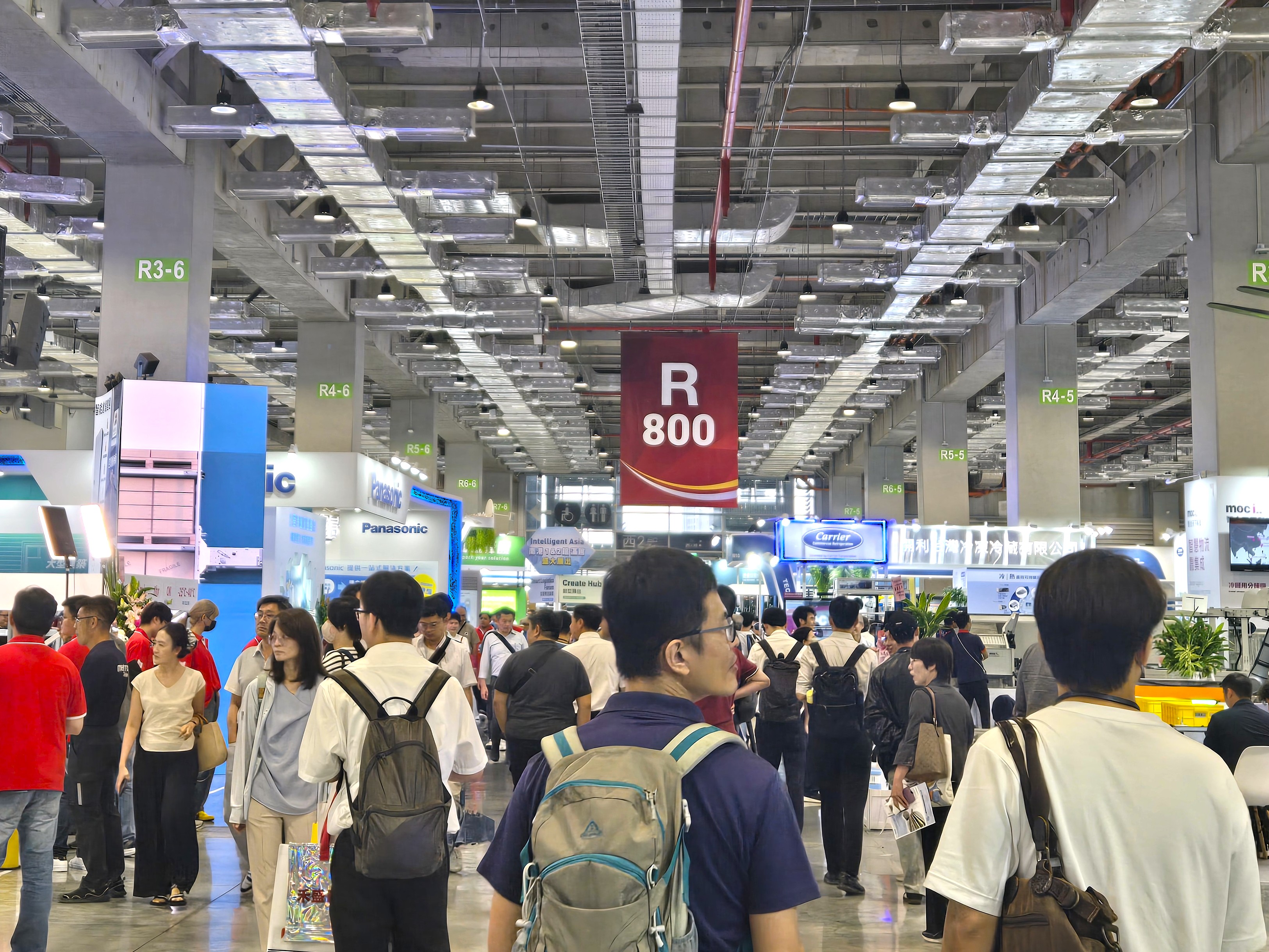

The Intelligent Asia series (incorporating the Taipei International Industrial Automation Exhibition) opened on August 20 at TaiNEX Halls 1 and 2. Against the backdrop of shifting international geopolitics and global supply chain restructuring, this year’s exhibition centered on "AI Robotics." Featuring over 1,000 exhibitors from 16 countries and more than 4,500 booths, the event drew a record-breaking 330,000+ visitors, underscoring Taiwan’s commitment to embracing AI and robotic technologies.

|

The exhibition spanned nine major sectors—including automation, robotics, 3D printing, smart molds, logistics, cold chain, lasers, fluid power, and mechanical components—showcasing Taiwan’s significant milestones in smart manufacturing, digital transformation, and net-zero emissions.

AI and Edge Computing: The Core Engines of Smart Manufacturing

A defining trend of the exhibition was the comprehensive integration of Artificial Intelligence (AI) and Edge Computing. Industrial PC and controller manufacturers showcased AI applications such as real-time machine monitoring, predictive maintenance, automated processing parameter optimization, and flexible scheduling, empowering machines with autonomous forecasting and optimization capabilities.

Many AI solutions were built on NVIDIA platforms. Notably, the introduction of humanoid robot simulation systems using NVIDIA Jetson Thor demonstrated inference speeds 66% faster than previous generations. This advancement significantly streamlines the transition from simulation to physical deployment, signaling an acceleration in the commercialization of humanoid robots.

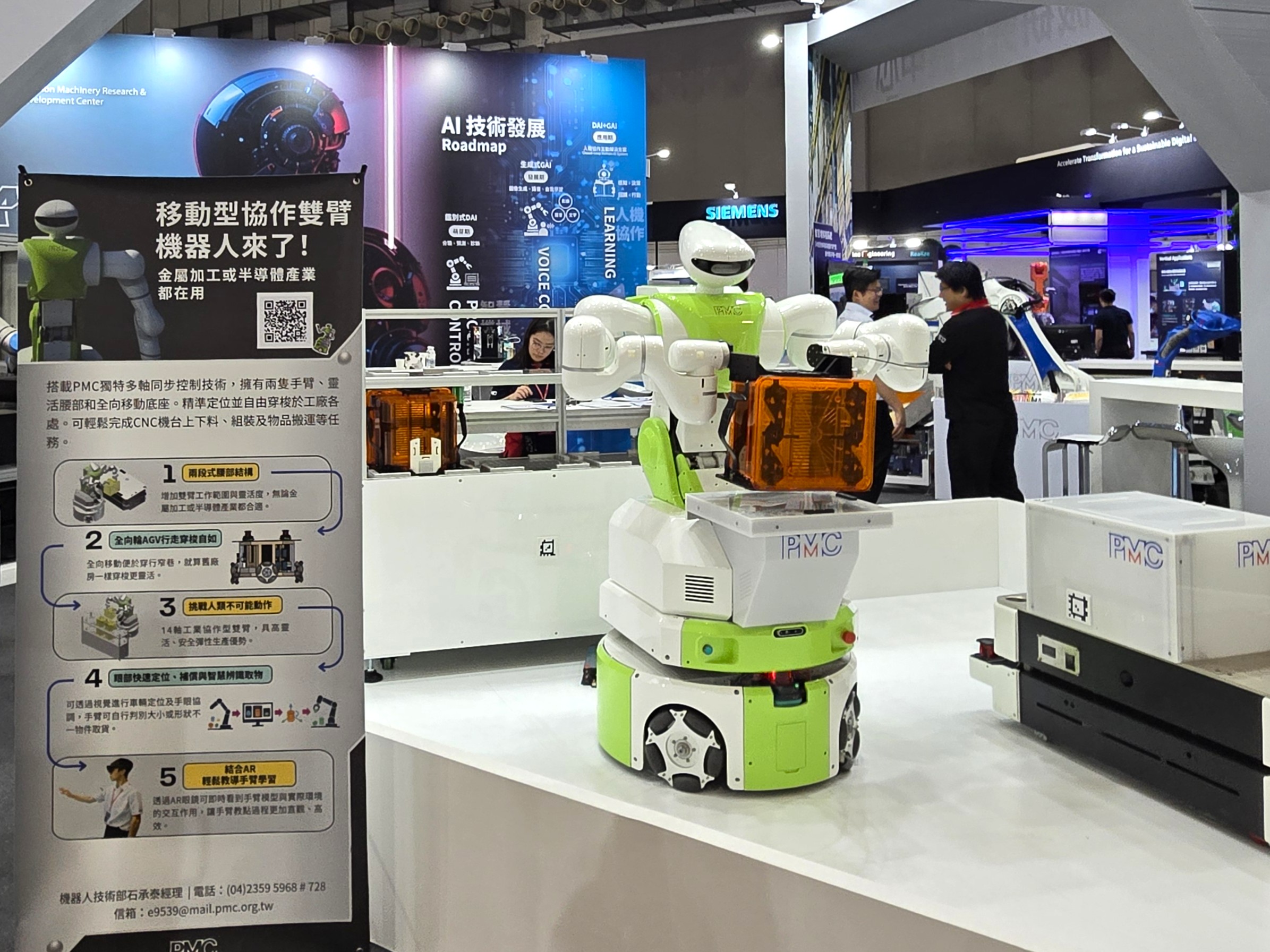

Robotics Evolution: Moving Toward Intelligent Collaboration

Robotic arm technology highlighted three major developmental trends:

-

Enhanced Collaborative Safety: New-generation collaborative robots (cobots) feature immediate shut-off sensors upon contact with foreign objects to ensure safe human-machine interaction.

-

Ubiquitous AI Vision: Integrated AI vision systems allow for complex tasks such as precision positioning and object differentiation.

-

Integrated Control Architecture: Consolidating AI core computing, motion control, and safety systems into a single platform resolves the latency issues found in traditional multi-platform setups.

In terms of application, robotic arms have expanded from traditional manufacturing into the service sector, including frozen food production lines, logistics sorting, and even beverage preparation.

|

Cyber-Physical Integration: The Key to Industrial Upgrading

To navigate challenges like geopolitical tensions, tariffs, and carbon taxes, smart manufacturing solutions are leveraging Cyber-Physical Systems (CPS). By linking robotics and Digital Twin technology with management systems, companies can better manage production deployment, labor shortages, and cross-border operations.

Rapid Expansion into Diverse Fields

The exhibition demonstrated the deep penetration of robotics from industry into daily life:

-

Smart Manufacturing: Full-spectrum solutions from robotic arms and IPCs to AI system integration.

-

Service Robotics: Commercial applications in reception, guided tours, and hospitality.

-

Personal & Home: Smart wearables, personal transport, home care, and security robots.

-

Specialized Robots: Deepening applications in surgical procedures, agriculture, defense, and education.

|

Sustainability and Green Manufacturing

Driven by global ESG trends, AI-powered energy monitoring and storage systems were a focal point. Exhibitors presented smart solutions combined with green energy to help industries move toward sustainability, with a marked increase in demand for specialized equipment for high-cleanliness environments like semiconductor fabrication.

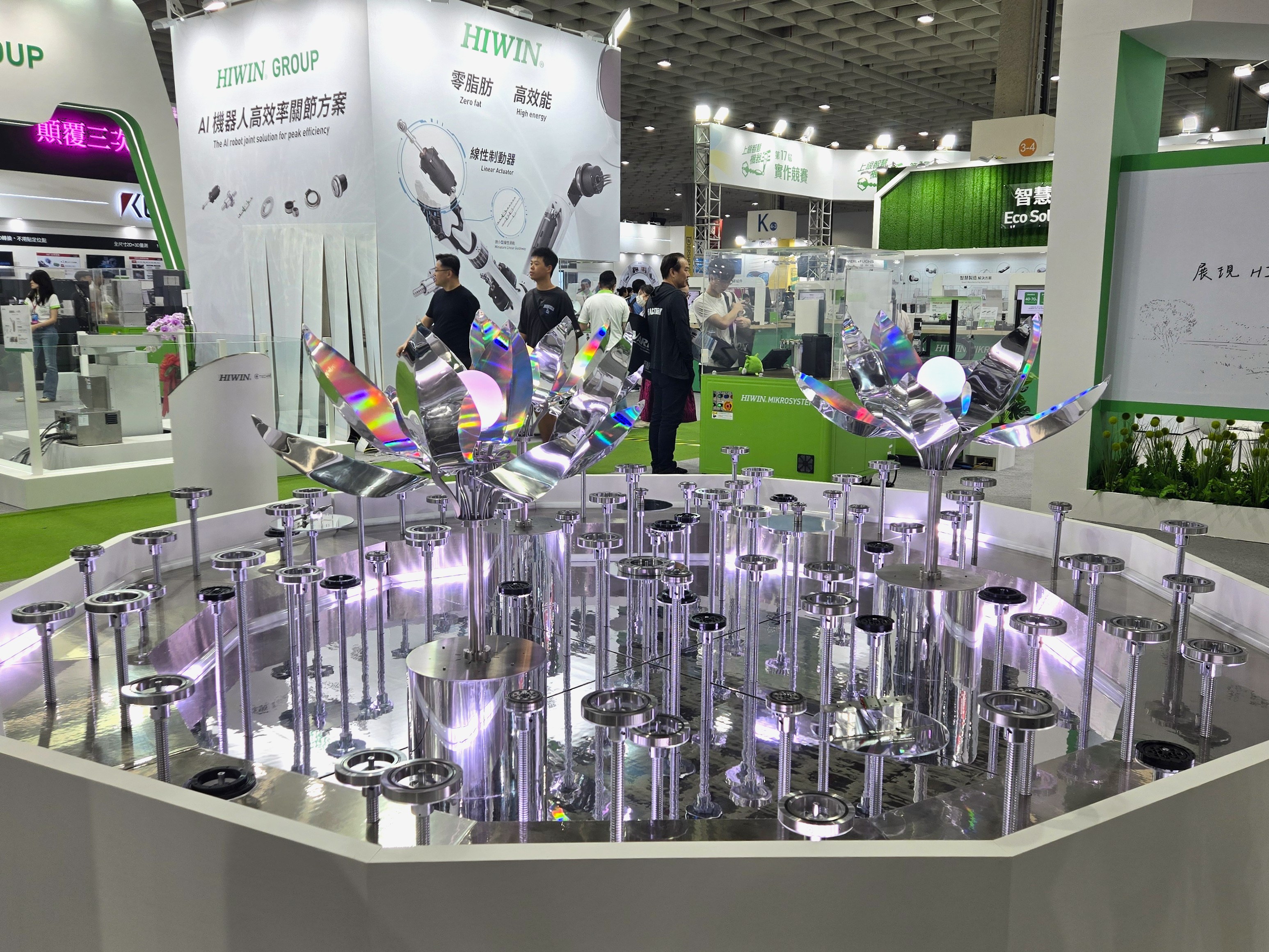

Accelerated Commercialization of Predictive Maintenance

The synergy between sensors and AI machine learning has matured into robust predictive maintenance solutions. These allow for predictable equipment inspections and preventative maintenance, drastically reducing downtime risks and reflecting the continuous refinement of foundational automation technologies.

Outlook The Taiwan Automation Intelligence and Robotics Association (TAIROA) estimates that AI robot innovation is driving a total upgrade of the manufacturing and service sectors. Taiwan’s output value in this field is expected to surpass NT$1 trillion in the near future. With the dual drivers of government policy and industrial innovation, Taiwan is poised to play an even more critical role in the global AI robotics supply chain.