Integration of Machine Tools and Component Sensing Applications: umati’s Long Road Ahead in the AIoT Era

By Special Correspondent Chen You-Hao

The machine tool industry, having undergone the Industry 4.0 revolution and embraced digital transformation through Industrial Internet of Things (IIoT) and Cyber-Physical Systems (CPS), is now riding the wave of Generative AI (GAI). This trend is expected to leverage big data to create added value across industries, prompting machine builders, system integrators (SI), and end-user manufacturers to adopt the open industrial communication interface standard umati, accelerating its implementation through collaborative efforts.

Modern manufacturing benefits from Industry 4.0 by integrating AIoT applications, including data collection via sensors, high-speed communication between devices, and cloud/edge AI processing for big data analytics. These advancements improve production efficiency, product quality, and reduce costs. They also enable production data management and optimization for flexible, customized manufacturing, aligning with global trends and paving the way for autonomous smart factories.

The key lies in merging IT systems at the application layer with diverse industrial network interfaces on the shop floor, ensuring high-speed, high-capacity, and high-precision communication. This facilitates seamless equipment connectivity, boosts efficiency and quality, and supports process automation and digital twins to achieve continuous automated production of quality goods. Ultimately, this drives energy savings and carbon reduction—now a core focus for the machine tool industry.

|

Source: Canva

OPC UA and umati: Layered Advancement for Application-Level Integration

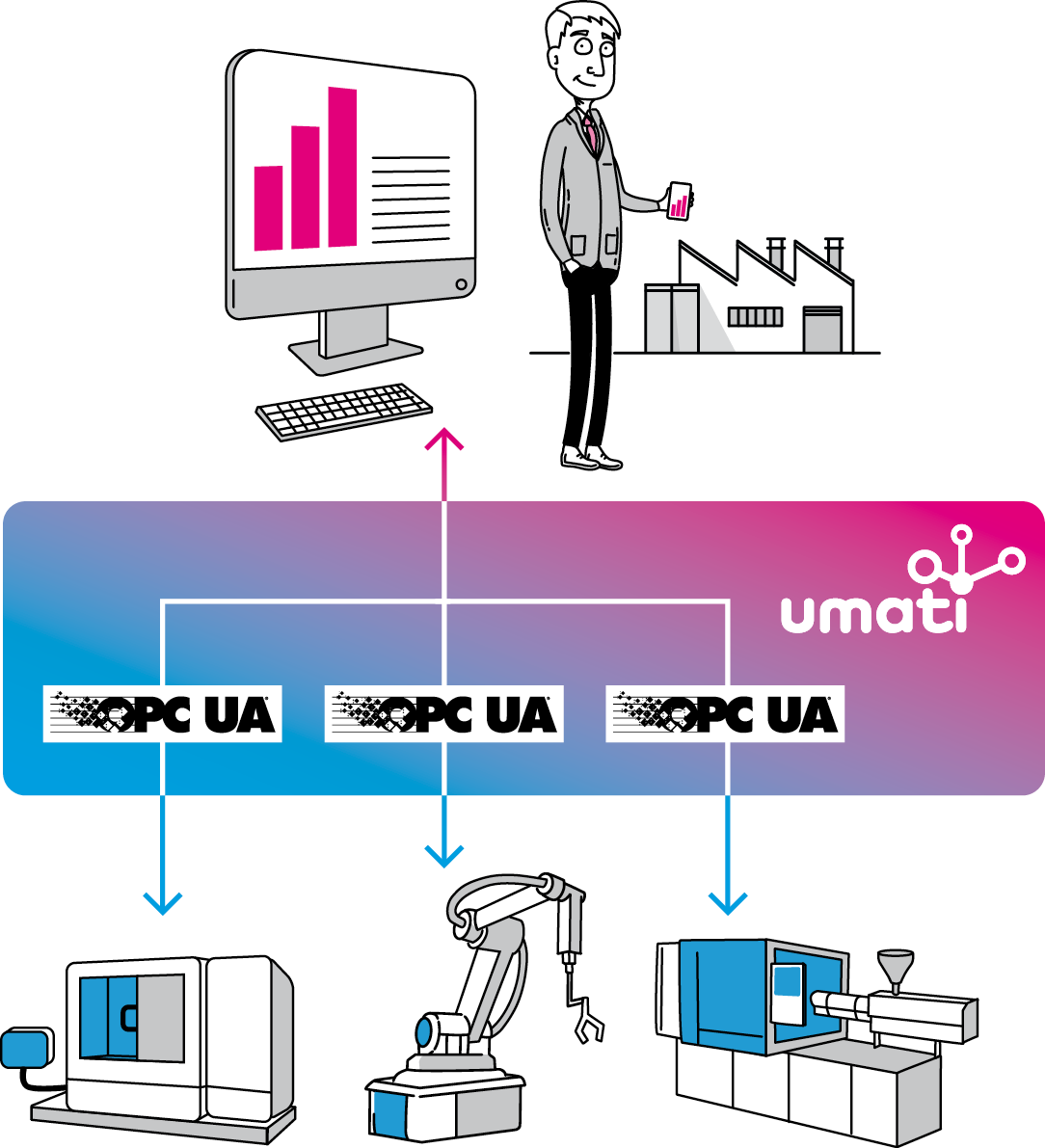

Industrial Ethernet protocols often suffer from low latency and limited interoperability, compounded by proprietary standards in IIoT environments, hindering Industry 4.0 progress. The OPC UA (Open Platform Communications Unified Architecture) standard addresses this by managing application-layer control, enhancing machine-to-machine (M2M) data exchange between machine tools and other production equipment. It breaks down barriers between different Ethernet networks, emphasizing cross-platform and vendor interoperability, and offers specialized communication formats for various industries.

umati—short for Universal Machine Technology Interface—is promoted by Germany’s VDW (Machine Tool Builders’ Association) and VDMA (Mechanical Engineering Industry Association). Built on OPC UA, it provides an open Ethernet protocol for industrial automation.

Its architecture includes an OPC UA server, a translation engine, and a data receiver. Machine status and codes from 110 machines serve as data sources, which umati’s receiver collects. Since machine data structures vary, the translation engine converts them into umati-specific OPC UA format. The OPC UA server then transmits this translated data to the control-side app.

OPC UA data uses web-based language for secure, simple transmission over Ethernet. Apps, equipped with umati gateways, receive OPC UA-formatted data and display process information to operators.

By adopting a common communication standard, the entire workflow—from order placement and design to production and logistics—becomes more streamlined. This reduces communication costs between equipment makers and users, accelerates IoT development, and enhances interoperability. Shared use of the umati trademark also boosts cross-industry marketing visibility.

|

Source:umati.org (2024)

Global Adoption and Taiwan’s Role

Since its introduction to industrial sectors in 2018–2019, umati has attracted OEMs, automation integrators, and manufacturers worldwide, enabling “plug-and-play” connectivity across manufacturing, process, and logistics ecosystems. This saves time and costs for end-users and lays the foundation for smart factories.

However, experts note that current umati users—both domestic and international—are mostly machine builders and end-users, and the data collected is not highly real-time for direct shop-floor processing. Component manufacturers face greater challenges in adopting umati, often opting to upload sensor data to controllers or use smart machine boxes (SMBs) for cloud integration.

PMC and ITRI Driving umati Expansion in Taiwan

The Precision Machinery Research & Development Center (PMC) is actively promoting umati in Taiwan, collaborating with VDW and TMBA during TMTS 2024 to showcase real-time equipment data on global dashboards. Future edge devices with built-in OPC UA/umati support will enable rapid integration for SIs and machine builders, even upgrading legacy equipment via SMBs for cloud connectivity and value-added services.

PMC has integrated umati into its SkyMars platform, supporting ERP and PaaS integration, and demonstrated real-time measurement monitoring during TMTS. Meanwhile, ITRI focuses on standardizing communication interfaces for CNC machines, robots, and automated storage systems, addressing issues like inconsistent data formats and SaaS incompatibility. Its IoT platform consolidates diverse protocols and supports runtime standards for SMBs and cloud services, fostering interoperability across industries.

Toward Industry-Wide Standards and AI Integration

Since Industry 4.0’s inception, Taiwan’s machine tool sector has leveraged government-backed smart machinery initiatives to connect thousands of machines to the cloud, accumulating vast datasets. Since 2021, efforts to establish common standards and develop microservice apps have enabled CPS and digital twin technologies, benefiting R&D, after-sales, and predictive maintenance.

TMBA reports over 400 company participations in standardization meetings, with 100 industry standards expected by end-2024. umati’s promotion further simplifies connectivity between machine tools and IT ecosystems, ensuring security and efficiency.

|

Future Outlook: System Integrators as Key Enablers

As AIoT and Generative AI reshape industrial operations—through predictive analytics, real-time production insights, and feedback loops for design optimization—the synergy between M2M communication and big data analytics will drive productivity gains and new business models.

Smart factories will require more connected devices generating diverse datasets for advanced analytics, bridging the IT-OT divide. umati’s integration of MES/ERP-related data (e.g., work orders, tooling, programs) sets the stage for AI-driven capacity analysis and demand forecasting. Ultimately, system integrators will play a pivotal role in deepening umati adoption and enabling value-added applications.