Research on Motor Abnormal State Monitoring Technology

Motors are among the most common devices in various machinery and play a critical role in equipment across major manufacturing industries. Unexpected motor operation anomalies can lead to equipment downtime or even large-scale production of defective products, resulting in waste and significantly increasing enterprise cost risks. The purpose of this study is to establish a motor anomaly monitoring system to address these pain points.

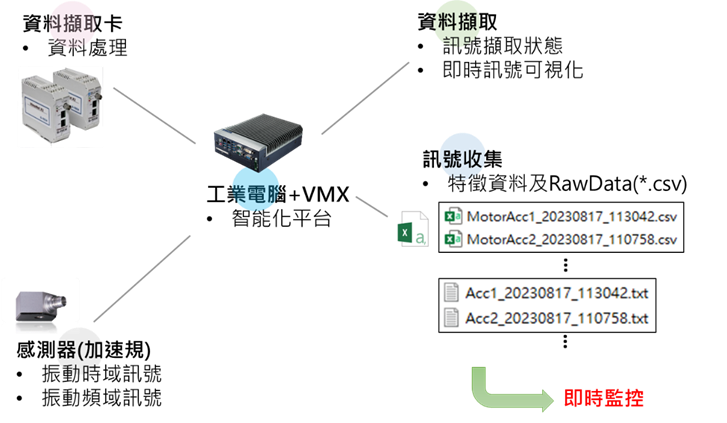

This research builds a data acquisition module on the VMX platform to capture vibration signals during motor operation. The data is then processed on the iMacloud platform using the AI Toolbox module for preprocessing and feature selection to classify motor abnormal states. The monitoring system can provide users with motor anomaly alerts in the future, helping manufacturers reduce downtime and waste, thereby improving machining efficiency through intelligent equipment.

Establishing Motor Abnormal State Monitoring

In the early days, when maintenance concepts were lacking, repairs were typically performed only after equipment failure occurred—a method known as Reactive Maintenance. This approach usually involves maintenance measures only after a failure has impacted production or operations, often resulting in production interruptions, high maintenance costs, and unpredictable downtime.

Later, the concept of Preventive Maintenance emerged, which involves maintenance based on time, usage frequency, or specific events to ensure equipment remains in optimal condition. However, this can lead to excessive maintenance frequency, difficulties in servicing hazardous equipment, inconsistent maintenance cycles, and increased labor and maintenance costs. Sometimes failures even occur immediately after maintenance.

To solve these issues, Condition-Based Maintenance and Predictive Maintenance have become widely adopted. These methods involve installing sensors on target equipment to continuously monitor operating conditions and setting thresholds to determine maintenance needs. Data collected from sensors is used to build predictive models, reducing labor and maintenance costs and avoiding unnecessary energy consumption during abnormal states.

Therefore, this study uses a dataset from the IEEE PHM Data Challenge for analysis, builds a data acquisition module on the VMX platform to capture vibration signals during motor operation, and integrates AI Toolbox functions into the monitoring system for anomaly detection. This system provides motor anomaly alerts, helping manufacturers reduce downtime and waste, and improve machining efficiency through intelligent equipment.

Data Acquisition Module

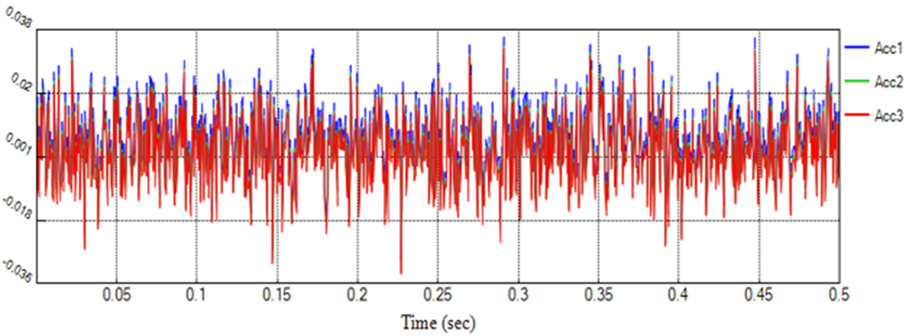

A three-axis accelerometer is installed on the monitored motor, and signals are imported into an industrial computer via a data acquisition card. The VMX machine networking system is integrated into the industrial computer. The module records raw vibration signals and extracts time-domain and frequency-domain features at fixed intervals. These features are collected and provided to the motor anomaly monitoring system. The system supports real-time online monitoring of motor status and issues alerts or initiates shutdown procedures when anomalies are detected. All operations are logged for future tracking.

|

|

| (a) | (b) |

Analysis Method

In real-world machine operations, opportunities to collect motor anomaly data are limited. The most common cause of motor anomalies is bearing damage. Therefore, this study uses a bearing life dataset created by the FEMTO-ST team. The dataset involves accelerated bearing degradation under heavy load using induction motors, with data collected every 10 seconds for 0.1 seconds at a sampling frequency of 25,600 Hz, covering the entire lifecycle from healthy to failed bearings.

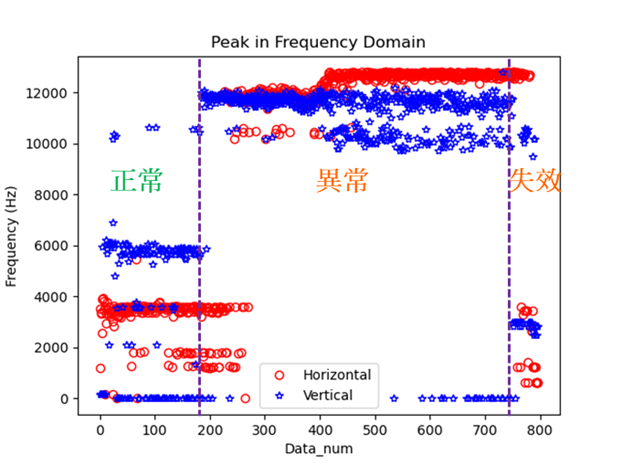

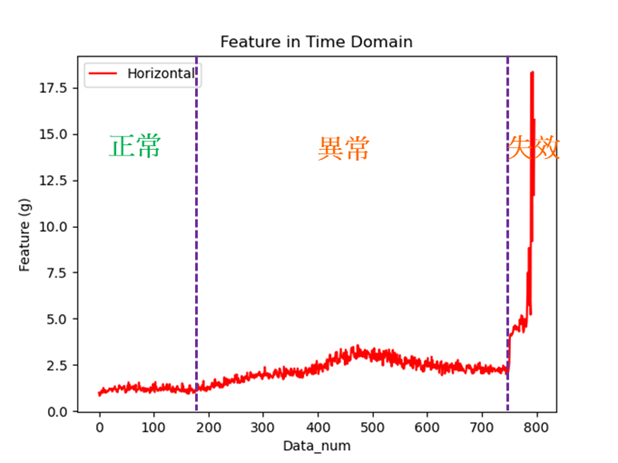

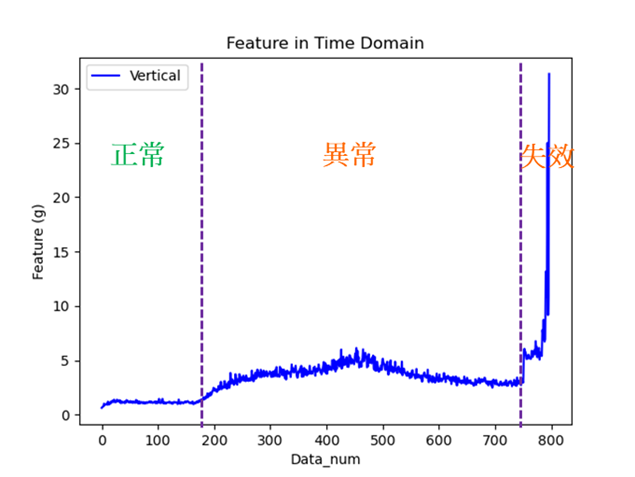

Using this dataset and the AI Toolbox, we classify bearing life stages into normal, abnormal, and failure states for motor monitoring. Vibration signal peaks often indicate equipment condition. Faults typically generate additional vibrations reflected in peak values, signaling anomalies that require inspection. By observing peak changes, mechanical faults such as bearing wear or gear defects can be diagnosed.

For example, bearing 2_2 was analyzed. During preprocessing, we divided the full lifecycle data into normal and abnormal signals based on peak distribution in time and frequency domains. In the frequency domain, signals were transformed using FFT, and peak values and corresponding frequencies were extracted. In the time domain, the top five peaks per signal were calculated as feature values. These distributions were visualized for analysis.

|

|

|

|

(a) Peak Distribution in the Frequency Domain |

(b) Time-Domain Feature Distribution of the Horizontal Sensor |

(c) Time-Domain Feature Distribution of the Vertical Sensor |

Data Analysis and Results

Observations suggest bearings experience progressive damage before complete failure, with noticeable changes in frequency-domain features during each stage. For bearing 2_2, anomalies appeared at the 184th data point (after 1,830 seconds), indicating partial damage. Complete failure occurred at the 750th data point (after 7,310 seconds).

Frequency-domain analysis showed high-frequency features emerging at 12,000 Hz around 1,830 seconds, while time-domain features began rising from 1g at the same time. Thus, 1,830 seconds was set as the boundary between normal and abnormal states. Later, low-frequency features (1,000–4,000 Hz) appeared after 7,310 seconds, with time-domain features rising sharply from 5g, marking the transition to failure.

Application Case

Company H applied this system to tool magazine motors, which affect whether the magazine operates normally. Despite automated feeding and machining, unexpected motor anomalies caused downtime and production delays. By collaborating with ITRI to implement this monitoring system, Company H achieved three benefits:

- Reduced labor costs: Accurate anomaly prediction allows scheduled inspections and replacements, avoiding sudden downtime.

- Lower maintenance costs: The system prevents excessive maintenance frequency, enabling better resource allocation.

- Reduced waste and energy loss: Immediate action upon anomaly alerts prevents defective products and unnecessary energy consumption.

|

Conclusion

This study applies data preprocessing, analysis, segmentation, and classification methods using the AI Toolbox to clearly define normal, abnormal, and failure states in bearing lifecycle data. These classifications support machine learning model training and integration into online monitoring systems, as demonstrated in the tool magazine motor case. Manufacturers using similar motors can leverage this system to reduce downtime, waste, and over-maintenance, saving labor and costs.

Future research may explore transfer learning for motors with similar specifications, incorporate additional signals (e.g., current, temperature, sound) to enhance classification accuracy, and refine anomaly categorization (e.g., stator or rotor faults) for faster troubleshooting and recovery.