Witzig & Frank: A Century-Old German Machine Tool Manufacturer Driving Innovation and Efficiency

During the AMB Metalworking Exhibition held in Stuttgart this September, I had the privilege of visiting Witzig & Frank, a century-old machine tool manufacturer located in Baden-Württemberg. This visit provided an in-depth look at how this company, with over 150 years of history, continues to innovate and maintain its leadership in precision machining. This article explores its success story from historical development and technological breakthroughs to future prospects.

Early Development and Transformation

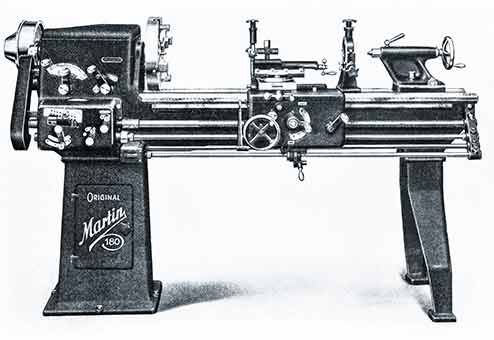

Witzig & Frank traces its roots back to 1865, when Karl Martin founded a small mechanical workshop, Mechanische Werkstätte, in Offenburg, Germany. Amid the booming industrial revolution of the late 19th century, the workshop gradually evolved into a specialized machine tool manufacturer. By 1919, the company focused on designing and producing machine tools for automotive components and precision machining industries.

In 1954, the company entered a new phase by establishing Witzig & Frank Maschinenbaugesellschaft mbH, marking its commitment to advanced machine tool technology.

|

Source:Witzig & Frank, FFG Group (2024)

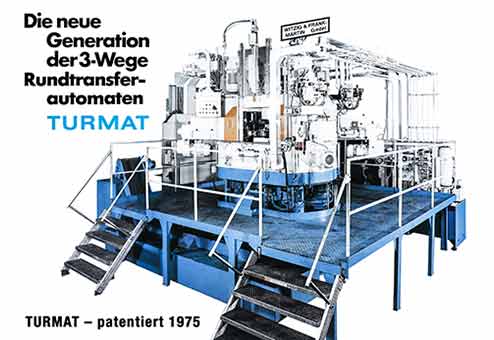

Technological Innovation: The TURMAT Rotary Transfer Machine

One of Witzig & Frank’s most significant breakthroughs came in 1975 with the launch of the TURMAT rotary transfer machine, designed for high-efficiency metalworking. TURMAT dramatically improved productivity and reduced costs, accelerating automation in industries such as automotive manufacturing. This innovation secured Witzig & Frank a strong position in the global market.

|

Source: TURMAT (2024)

Expansion and Strategic Acquisitions

In 1981, Witzig & Frank merged with K. Martin Maschinenfabrik, enhancing its technical capabilities and competitiveness. The 1990s saw the introduction of the TRIFLEX multi-station CNC machining center, offering versatility and precision for customized production.

Further expansion occurred in 1996 with the acquisition of LSA rotary table systems, reinforcing leadership in rotary machining technology.

Integration into Global Networks

In 2013, Witzig & Frank joined the FFG Group, gaining access to global resources and strategic alliances. This integration enabled worldwide promotion of its technologies, particularly in automation and high-efficiency production. In 2017, the company introduced a new TRIFLEX design, improving flexibility and precision for modern manufacturing. Today, as part of the K.R. Pfiffner Group, Witzig & Frank specializes in high-precision rotary transfer machines for automotive, electronics, and industrial sectors.

TURMAT Rotary Transfer Machine Overview

The TURMAT series features modular designs with 4–12 stations and up to 33 machining units, ideal for complex cubic workpieces requiring 3–5-sided machining. It integrates multiple processes—drilling, milling, threading, honing, grinding, turning, broaching, forming, annealing, measuring, inspection, and assembly—within a single center, maximizing efficiency.

Key Specifications:

- Stations: 4–12

- Spindle Speed: Up to 12,000 rpm

- Max Workpiece Diameter: 130 mm

- Max Workpiece Length: 150 mm

- CNC Axes: Up to 60

Advantages:

- High-efficiency multi-station machining

- Space-saving design

- Superior precision and consistency

- Significant cycle time reduction

- Advanced automation and flexibility

Challenges:

- High initial investment and transport costs

- Limited adaptability for small-batch production

- Complex maintenance requirements

Industry Applications

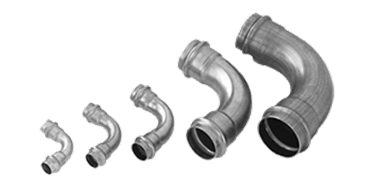

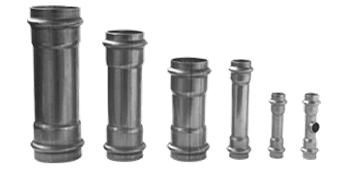

TURMAT excels in producing stainless steel fittings requiring simultaneous precision machining under high pressure. However, its flexibility is limited for highly diverse product lines.

The image above shows examples of workpieces processed by the TURMAT machine, including stainless steel bent press fittings and straight press fittings. TURMAT is one of the few rotary transfer machines on the market equipped with forming capabilities. Since stainless steel forming requires extremely high pressure, TURMAT performs finishing operations simultaneously at the front and rear stations to ensure product accuracy and consistency. This places very high demands on the machine’s stability, which must be maintained during long periods of high-speed machining.

However, a single rotary transfer machine also has certain limitations. By changing fixtures, it can efficiently process product series with similar machining operations, but it cannot flexibly handle highly diversified product requirements. This gives TURMAT a clear advantage for applications with specific machining needs, but its flexibility is relatively low in environments requiring diverse product production.

|

|

Competitive Strategy

Facing intense competition in the global machine tool manufacturing market, Witzig & Frank has adopted a diversified competitive strategy. First, the company focuses on technological innovation and specialization in rotary transfer machines, while continuously updating its product line. By developing machine tools such as the TRIFLEX and LSA series, Witzig & Frank has further enhanced automation and flexibility.

After joining the FFG Group in 2014, Witzig & Frank leveraged FFG’s global resources and network, achieving significant breakthroughs in the Asian market. This international expansion enabled the company to provide customized production solutions for major enterprises, such as Gree, the world’s largest air conditioner manufacturer. The order, valued at €15 million, highlights the company’s competitiveness in high-capacity and tailor-made solutions.

Witzig & Frank also employs a customization strategy, designing machining processes tailored to each customer’s unique requirements. This “one-stop turnkey” solution gives the company an edge in a highly competitive market, particularly for mass production of precision components. In addition, the company emphasizes comprehensive after-sales service to ensure long-term customer support, strengthening customer loyalty.

Through these strategies, Witzig & Frank has successfully established a solid presence across multiple industries, especially in the production of automotive parts and large-scale precision industrial equipment.

Talent Development and Sustainability

Shortage of Skilled Professionals (Fachkräftemangel) is one of the major challenges currently facing Germany, particularly in sectors such as manufacturing, IT, engineering, and healthcare. Due to an insufficient supply of skilled labor, market demand cannot be met, and the problem is worsening as Germany experiences population aging, declining birth rates, and an outflow of young talent.

Causes of Fachkräftemangel:

- Demographic Changes: Germany’s labor market is deeply affected by an aging population. As the baby boomer generation gradually retires, the number of young people entering the workforce is insufficient, making it difficult for companies to find enough skilled workers to fill vacancies.

- Technological Shifts: With the advancement of Industry 4.0 and digitalization, demand for highly skilled workers has increased, especially those with expertise in digital technologies and automation systems. However, the supply of qualified talent in these areas remains limited.

- Mismatch Between Education and Vocational Training: In some industries, vocational training does not align with actual business needs, resulting in a gap between workers’ skills and new technologies, leaving market demand unmet.

To address the widespread shortage of skilled professionals in Germany’s manufacturing sector, Witzig & Frank has adopted a comprehensive talent development strategy. The company actively participates in Germany’s dual education system (Duales Ausbildungssystem), which closely integrates theoretical learning with practical training. This approach not only ensures the quality of technical talent but also establishes a stable talent pipeline for the company.

In terms of industry-academia collaboration, Witzig & Frank has established long-term partnerships with local universities and research institutes (such as the Forming Technology Research Institute) to jointly conduct technology development and talent training. This collaborative model enables the company to stay abreast of the latest industrial technology trends while providing young engineers with valuable hands-on experience. Through this talent development system, the company continuously strengthens its innovation capabilities and secures a solid foundation for sustainable growth.

Conclusion

Witzig & Frank’s success is not only built on its continuous investment in technological innovation but also on its long-standing partnerships with leading global manufacturers. The company has accumulated extensive experience in providing high-efficiency production equipment and meets diverse customer needs through customized solutions. In particular, in the automotive industry, Witzig & Frank’s equipment has been adopted by several of the world’s top car manufacturers, becoming an indispensable part of their production processes.

Looking ahead, Witzig & Frank will continue to drive the development of industrial automation and smart manufacturing technologies. Under the framework of Industry 4.0, the company actively explores new technological applications to deliver more innovative solutions for global manufacturing. As the industry moves toward digitalization and intelligent transformation, Witzig & Frank will further strengthen its leadership in precision machining and automation technologies, continuing to provide cutting-edge technology and efficient solutions across various sectors.

With a history spanning more than 150 years, Witzig & Frank has evolved from a local mechanical workshop into a globally renowned machine tool manufacturer. Its journey exemplifies technological innovation, international collaboration, and globalization, making significant contributions to the advancement of modern manufacturing.