The Continuous Evolution of Machine Tools: Insights into Process Integration and Factory Automation from JIMTOF 2022

Since its inception in 1962, the Japan International Machine Tool Fair (JIMTOF) reached its 31st edition this year, marking its return as a physical exhibition after a four-year hiatus. Under the theme "Open the door to the future — Meet the technologies move the world forward," the event focused on solving the various challenges faced by the manufacturing industry to drive future development. This article shares the current state of technological advancements in Process Integration and Factory Automation as observed at the exhibition.

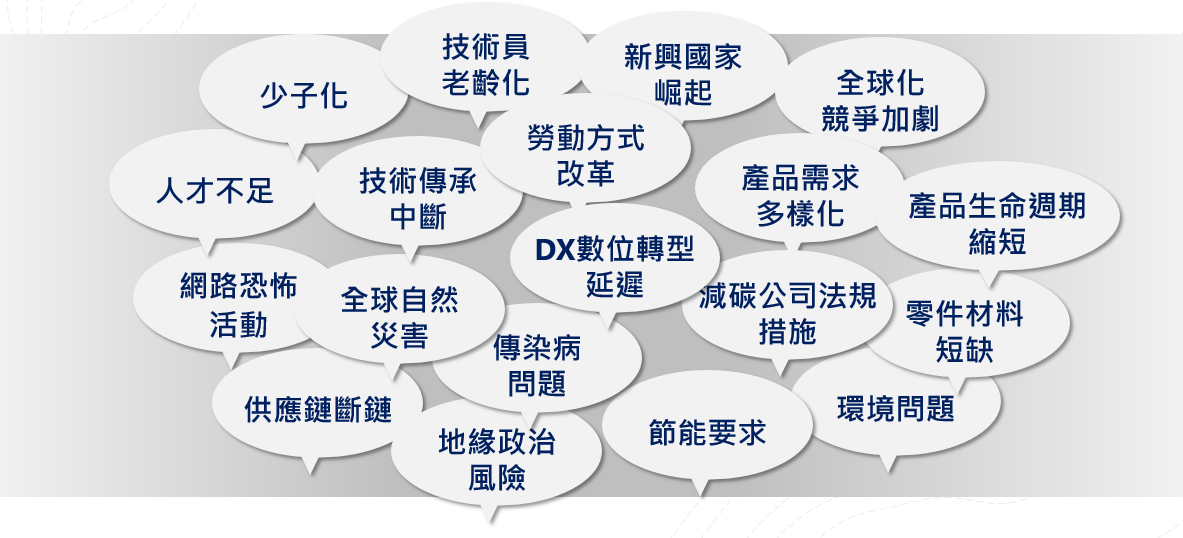

Impact of Manufacturing Challenges on the Shop Floor

Modern society is grappling with a shrinking labor force, an aging industry, delays in skill succession, the demand for digital applications, and the social responsibility of environmental sustainability. The manufacturing sector is no exception. Derived issues include labor shortages due to declining birth rates, insufficient time for personnel to accumulate experience via traditional methods, and the need for high-mix, low-volume production which leads to frequent process redevelopment and tool/fixture changes. Combined with rising operational costs due to carbon reduction mandates, maintaining both functionality and profitability on the shop floor has become a significant challenge.

|

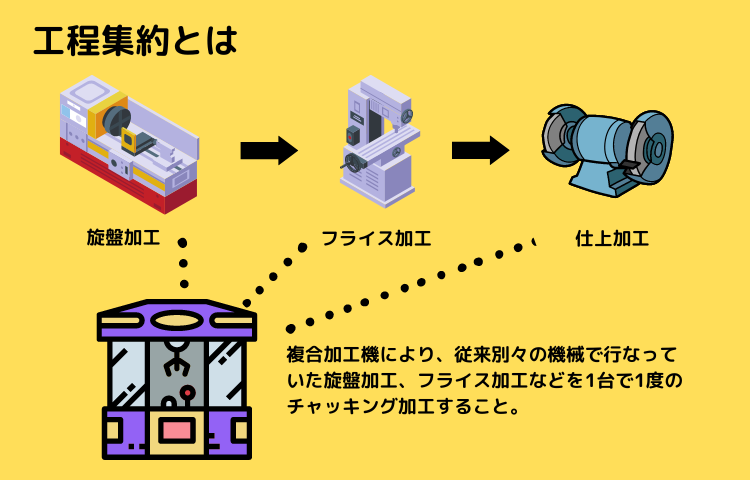

Process Integration

Process integration refers to consolidating multiple operations previously performed on different machines into a single setup. A product typically undergoes various traditional machining methods—turning, milling, drilling, gear hobbing, deburring, chip cleaning, finishing, and grinding. Integration merges these into one machine, alongside in-machine measurement, visual inspection, and even additive manufacturing. This results in higher precision, increased machine uptime, extended unmanned operation, and reduced work-in-progress (WIP) management.

|

-

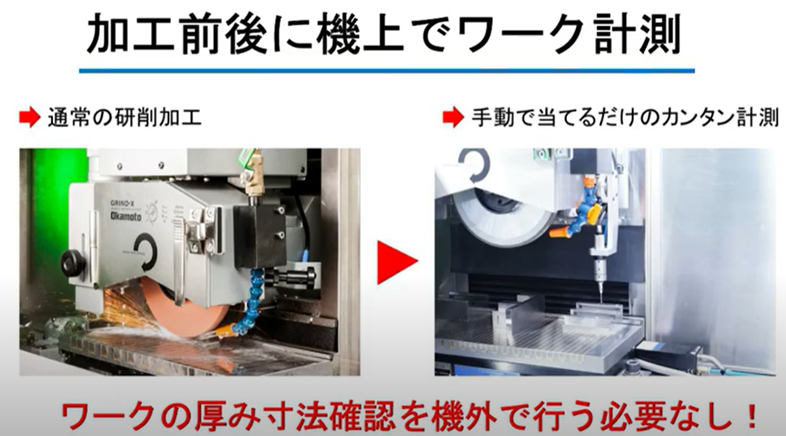

In-Machine Measurement: By utilizing in-machine measurement to inspect surfaces and geometric features, operators can set workpieces origins before machining and automatically correct offsets during the cycle. This ensures dimensions stay within tolerance without removing the workpiece, thereby enhancing precision.

-

Example: Okamoto demonstrated a surface grinder that uses "Quick Touch" technology via a touch probe to automatically measure workpieces and generate compensation programs.

-

In-Machine Measurement for Okamoto Grinders

-

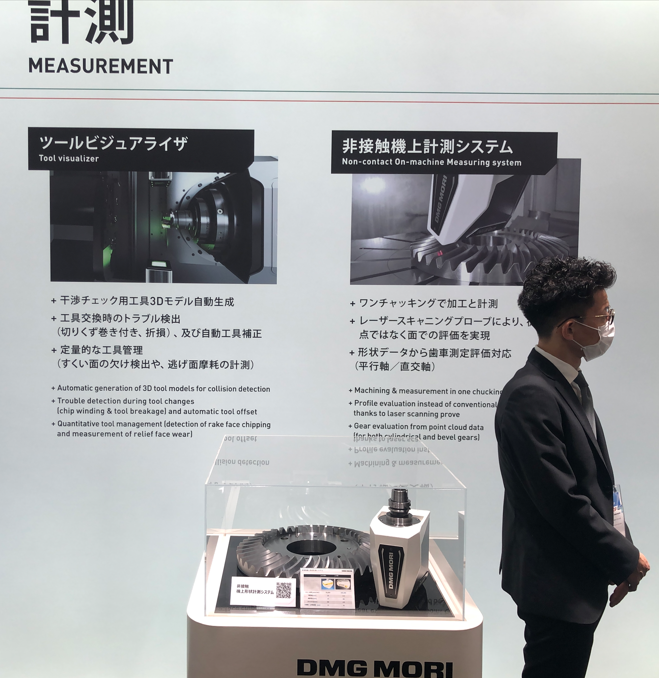

Example: DMG MORI showcased laser-based non-contact measurement for gear machining, where traditional probes reach their limits. This system can also be integrated into tool holders and stored in the tool magazine to generate 3D models for detecting tool wear or breakage.

-

DMG MORI Non-Contact In-Machine Measurement

-

-

Multi-Face Grinding: Process integration is often achieved by using parallel twin-spindles or indexing tables to complete front, back, or multi-side machining in a single setup.

-

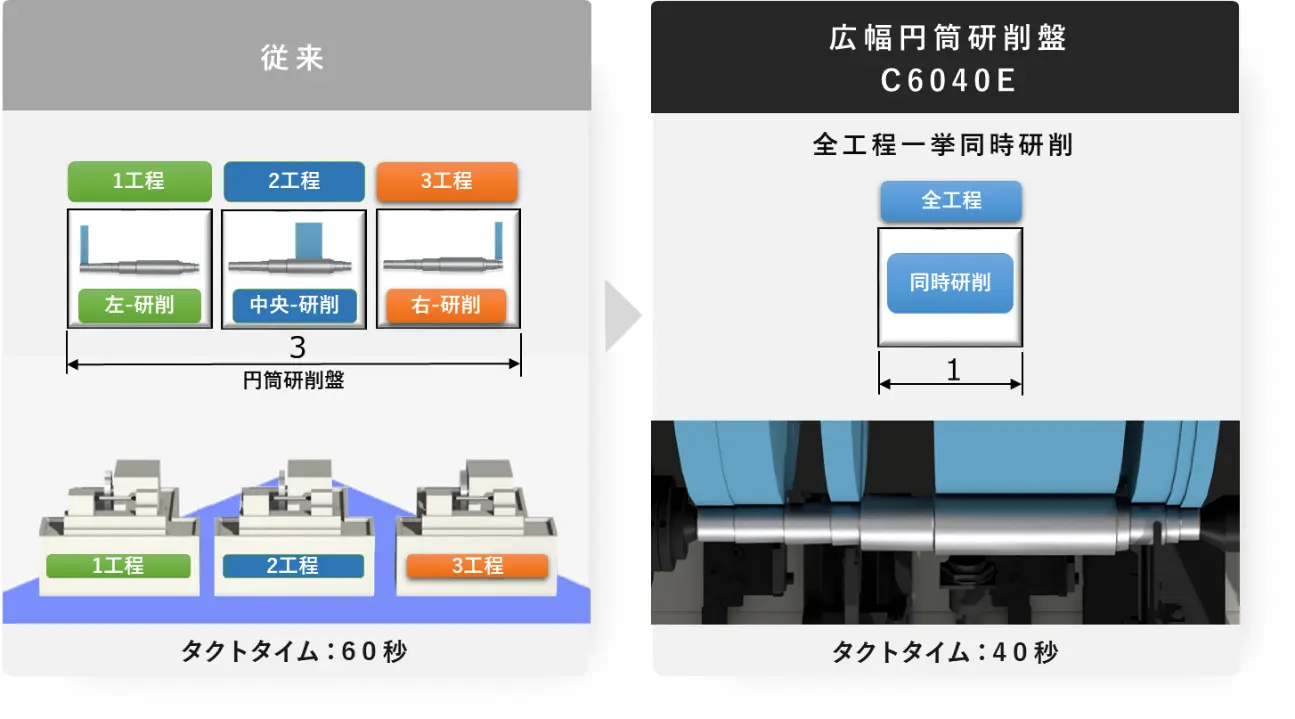

Example: JTEKT’s C6040E cylindrical grinder integrates a centerless grinder's twin-support spindle with a headstock, tailstock, and steady rest to process different diameters of a single workpiece (such as EV motor shafts) in a space-saving, high-efficiency layout.

-

Multi-face Machining: A Case Study of JTEKT Cylindrical Grinder C6040E

-

-

Multi-Tasking Consolidation: Brother Industries introduced the SPEEDIO M200Xd1, featuring the new CNC-D00 multi-axis control. With a tilting axis (+120° to -30°) and a DD rotary axis, it houses a 28-tool ATC. Its dual-contact spindle support provides stable turning capability, allowing turning, milling, and tapping to be completed on a single compact machine.

-

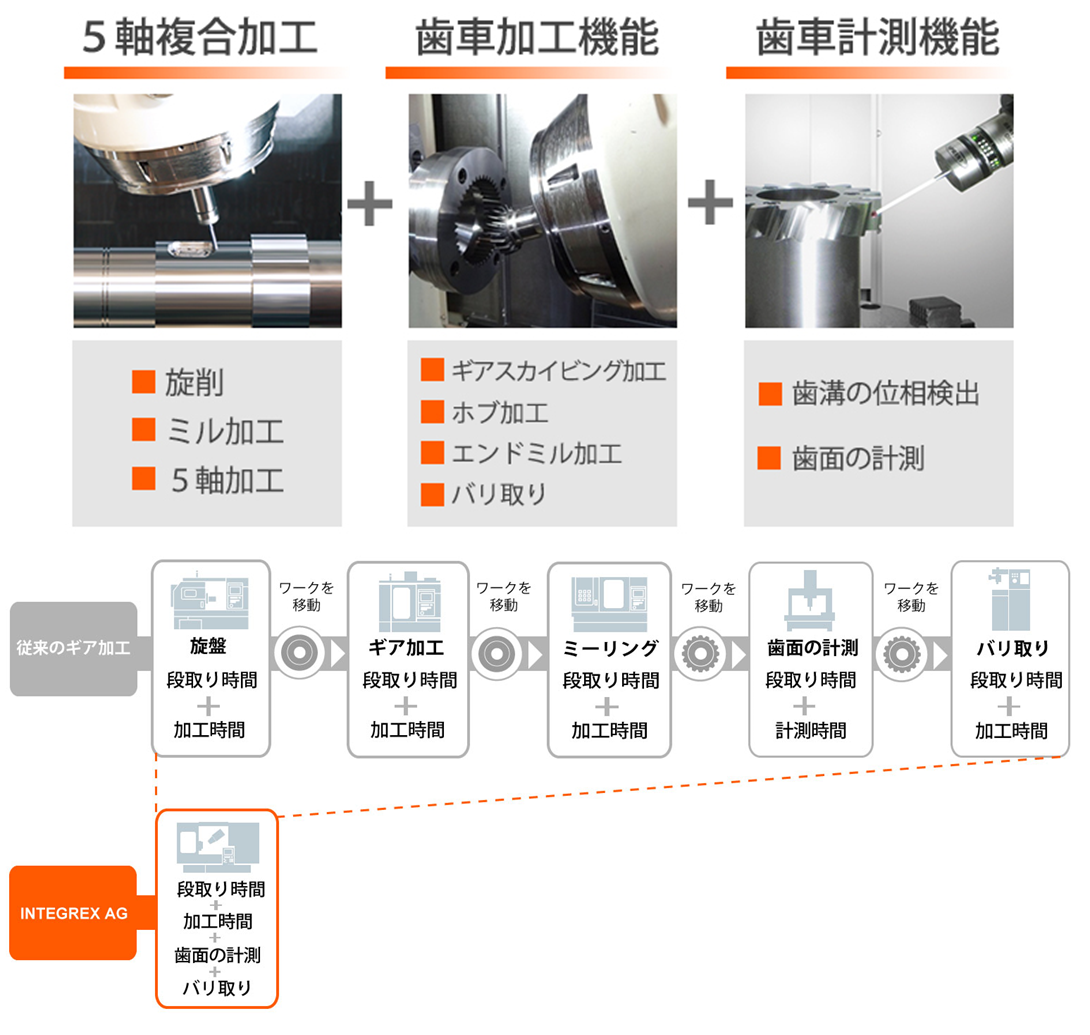

Process Integration for Gear Machining in YAMAZAKI MAZAK Multi-tasking INTEGREX AG Series

-

Specialized Gear Machining Integration: For the EV market, YAMAZAKI MAZAK’s INTEGREX AG series combines five-axis multi-tasking with gear-specific functions. It integrates skiving, hobbing, end milling, and deburring with final gear measurement into one controller, significantly shortening production cycles.

-

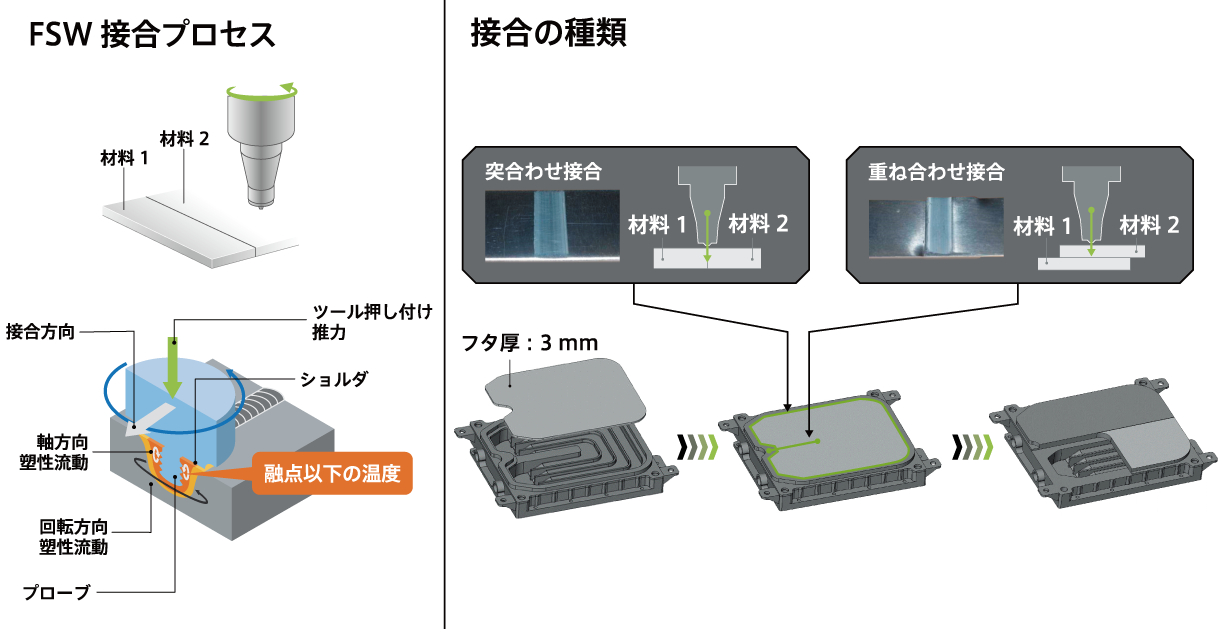

Friction Stir Welding

-

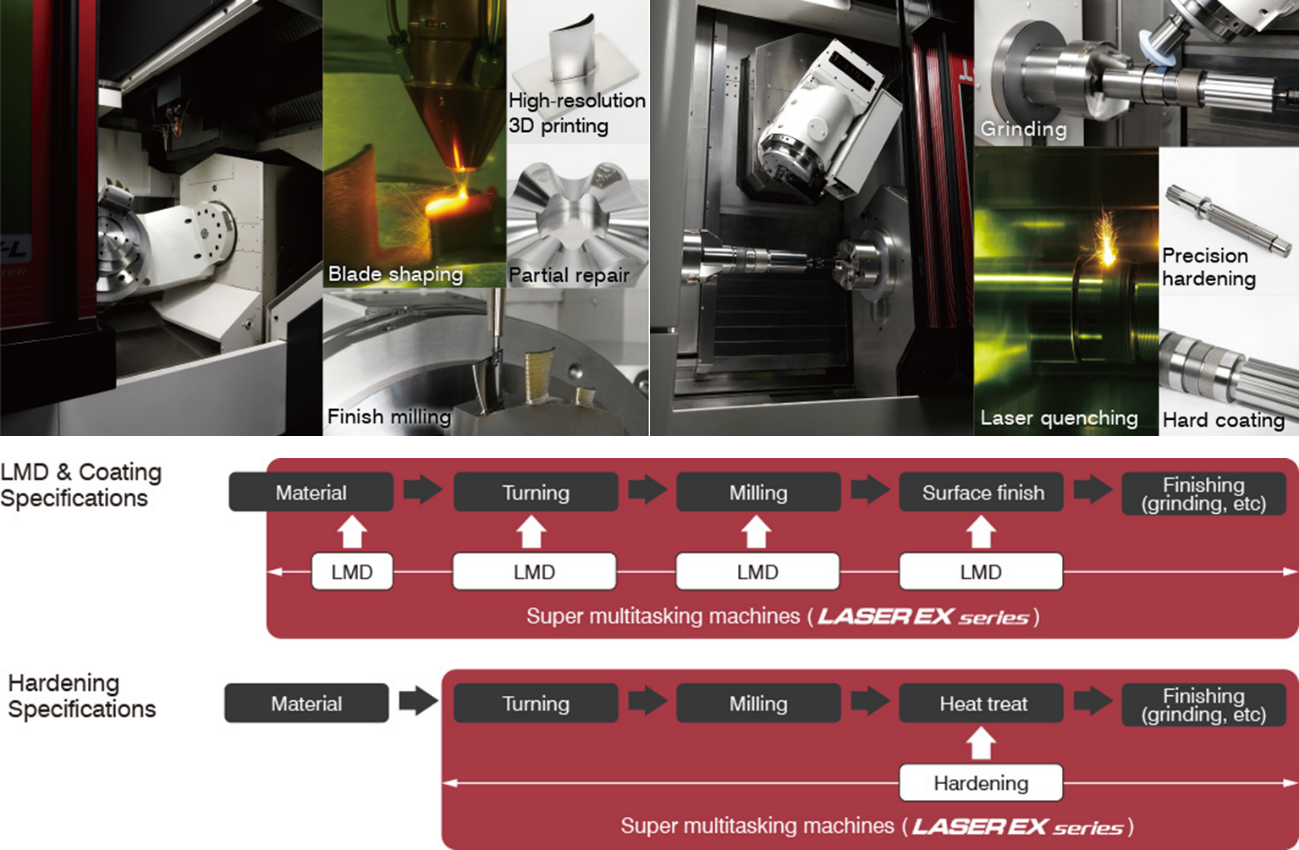

Special Process Integration (AM & FSW): JIMTOF featured an Additive Manufacturing (AM) zone for "free-form manufacturing." Additionally, Friction Stir Welding (FSW) is gaining traction for EV heat sinks and semiconductor cooling plates. OKUMA’s LASER EX series represents the pinnacle of this integration, combining subtractive machining, AM, quenching, and coating into a single "flagship process-intensive machine."

-

OKUMA Special Process Integration

Automation

To maximize machine and factory value amidst labor shortages, the industry is moving toward long-term unmanned operation. This requires solving peripheral issues such as chip management, tool breakage, and workpiece cleaning.

-

Challenges in Long-Term Machining: Chips, coolant, and oil mist are the primary causes of downtime.

-

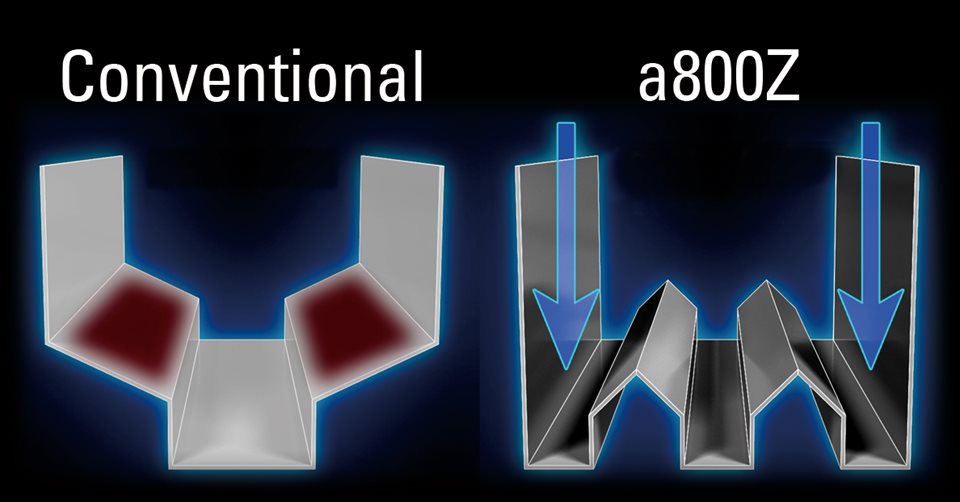

MAKINO’s a800Z features a vertical design with three chip channels and stainless steel covers to prevent chip adhesion.

-

Chip Disposal Design within the Machining Envelope of the New MAKINO a800Z

-

DMG MORI uses AI and machine vision to analyze chip accumulation and generate optimal cleaning paths.

-

AI-Generated Optimal Cleaning Paths by DMG MORI

-

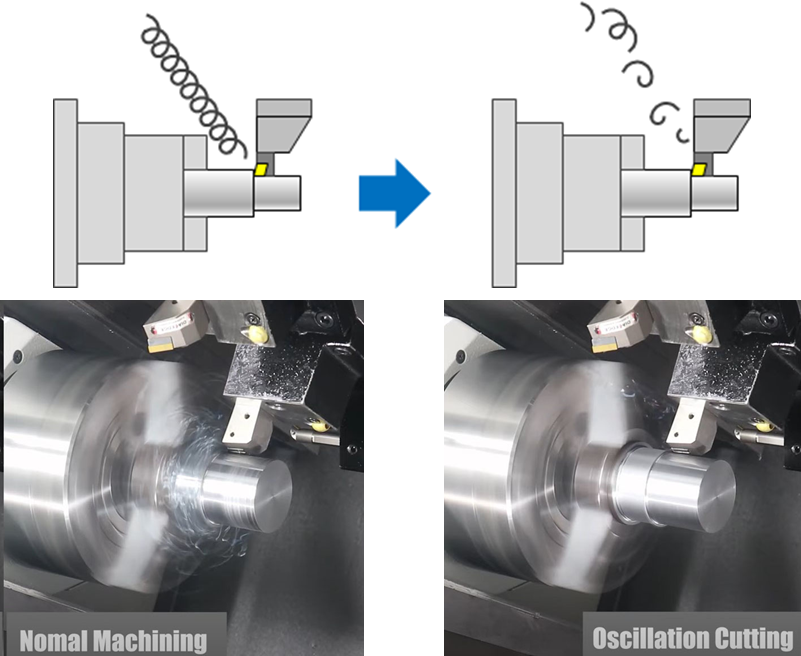

Nakamura-Tome utilizes "vibration cutting" to break long, stringy chips into small pieces, preventing entanglement.

-

Vibration Cutting Implementation by Nakamura-Tome Precision Industry

-

-

Automatic Workpiece Exchange Systems: Matsuura expands machine capability by stacking large volumes of pallets, allowing a single machine to handle diverse workpieces for extended periods. For lathes, Nakamura-Tome developed the "Hakobee" peripheral, which coordinates with gantry loaders or robot arms to manage the entire flow from raw material input to finished product stacking.

-

Matsuura Side-Mounted Multi-Pallet Exchange Magazine

-

Nakamura-Tome Side-Mounted Automated Material Handling and Storage

-

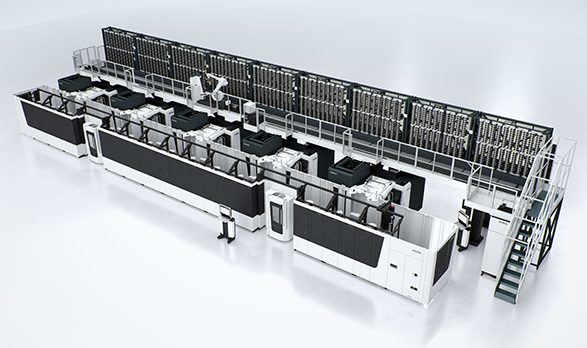

Automated Tool Management: DMG MORI’s CTS (Central Tool Storage) uses a mobile robot arm to load/unload tools from a central rack to individual machine magazines via a Tool Setup Station (TSS), allowing tool changes without interrupting the machining process.

-

DMG MORI Large-Capacity Tool Storage System (CTS)

-

Robotic Applications (Collaborative & AMR): The trend is shifting toward Collaborative Robots (Cobots) and Autonomous Mobile Robots (AMR).

-

DMG MORI’s "MATRIS Light" allows a cobot on a trolley to be moved manually between machines.

-

DMG MORI MATRIS Light: Trolley-Based Loading and Unloading Support System

-

MAKINO’s iAssist is an AMR that navigates structured environments using 5G and LiDAR to transport workpieces and tools, unlike traditional AGVs which require fixed paths.

-

MAKINO iAssist Smart Assistant (AMR)

-

The Logic Behind Integration and Automation

The realization of these technologies relies on the synergy between hardware (miniaturized sensors, wireless power) and software. Integrated machining cycles within the controller—rather than independent CAM software for turning and milling—are essential for shop-floor implementation. Furthermore, "Digital Twin" assistance, such as OKUMA’s smarTwinCELL, provides intuitive interfaces like "ROID Navi" and factory layouts to speed up setup. High flexibility via shared interfaces and modular expansion (optional pallet systems) ensures a higher ROI for users.

Conclusion: The Continuous Evolution

As a manufacturing powerhouse, Japan is responding to a shrinking labor force and global competition by pivoting toward highly automated, process-intensive multi-tasking machines. At JIMTOF 2022, the emphasis shifted from "flashy" tech demos to pragmatic solutions for labor shortages and sustainability. These challenges closely mirror those faced by the manufacturing industry in Taiwan, making Japan’s strategic solutions a vital reference for the advancement of our own machine tool industry.