AI-Based Energy Consumption Prediction and Precision Carbon Footprint Establishment for Machine Tools

I. Introduction

According to the International Energy Agency (IEA), approximately three-quarters of global carbon emissions in 2016 were energy-related. The industrial sector accounted for 30% of this, with over 24% coming directly from energy consumption, highlighting its critical role in the decarbonization process. As the core of industry, manufacturing not only consumes vast energy but also generates waste and emissions during raw material conversion. In 2018, manufacturing energy use represented 77% of the industrial sector.

While the push toward Industry 4.0 and 5.0 has increased production value, the high energy consumption characteristic of manufacturing intensifies environmental pressure while simultaneously offering opportunities for energy saving. Machine tools, in particular, significantly impact the overall manufacturing energy profile. Precise energy consumption prediction and efficiency improvements are, therefore, vital strategies for reducing waste and achieving sustainable development.

II. Establishing AI Prediction Models for Machine Tool Energy Consumption

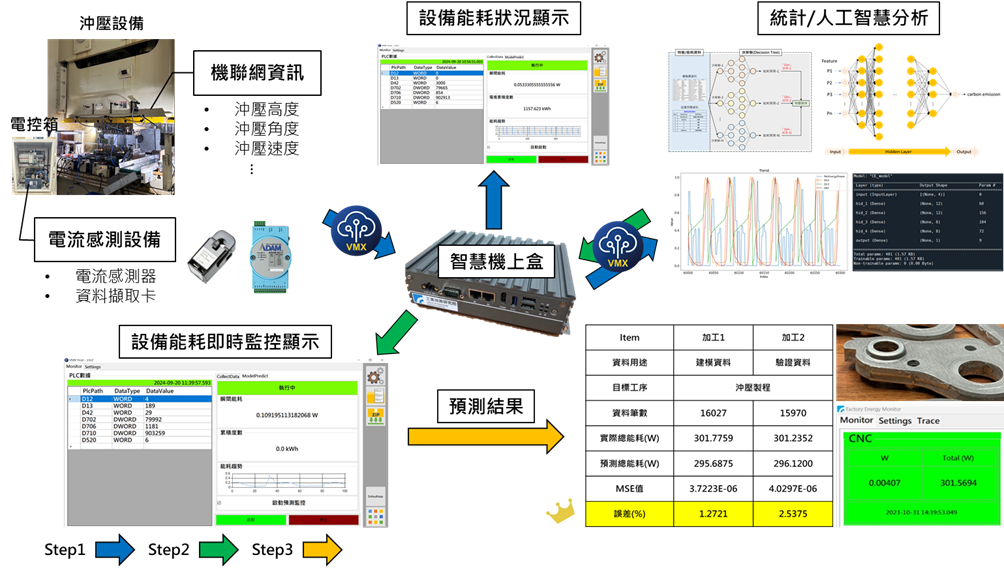

In response to global low-carbon trends and environmental regulations, energy monitoring has become a key path to sustainability. This research establishes an AI-based energy monitoring technology to solve digital zero-carbon transformation challenges. The signal acquisition module is built on the VMX platform, collecting current and controller data via the Industrial Internet of Things (IIoT). Statistical methods extract features, followed by Random Forest algorithms for feature selection. A Deep Neural Network (DNN) is used for modeling, maintaining verification errors within 3%.

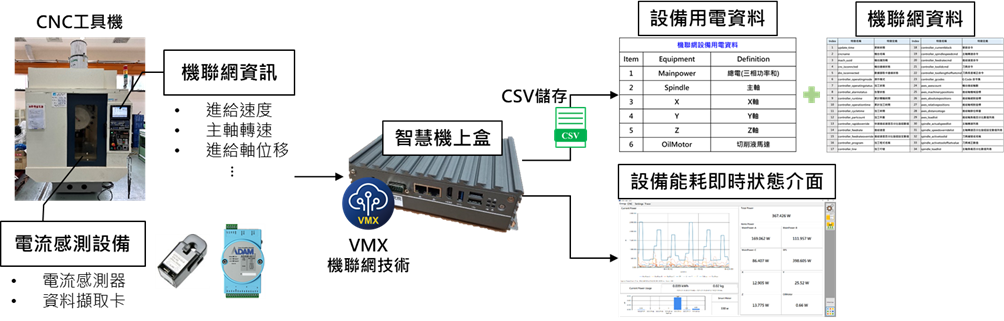

(1) Data Acquisition Module

This module installs current sensors on target machines and key components. An independent Intelligent Edge Box serves as the data collection and analysis platform, integrated with the VMX system to read real-time controller states.

-

Strategy: Data is recorded every 0.1 seconds.

-

Output: Each machining cycle is saved as a file containing 34 IIoT features and component-specific energy data.

-

Visualization: A real-time interface allows personnel to monitor energy status immediately.

|

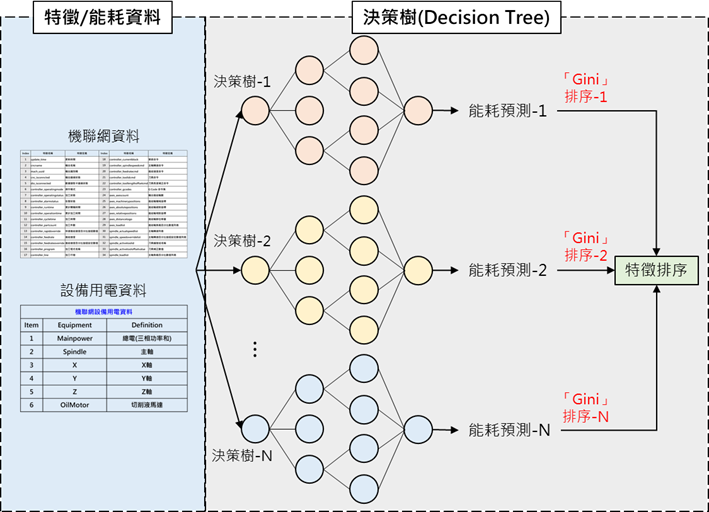

(2) IIoT Feature Selection

34 features are extracted from the controller. The Random Forest (RF) algorithm is employed to rank feature importance. By using "Bootstrap" sampling to build multiple decision trees and utilizing the "Gini" index, the system identifies parameters most highly correlated with energy consumption, optimizing the model's input variables.

|

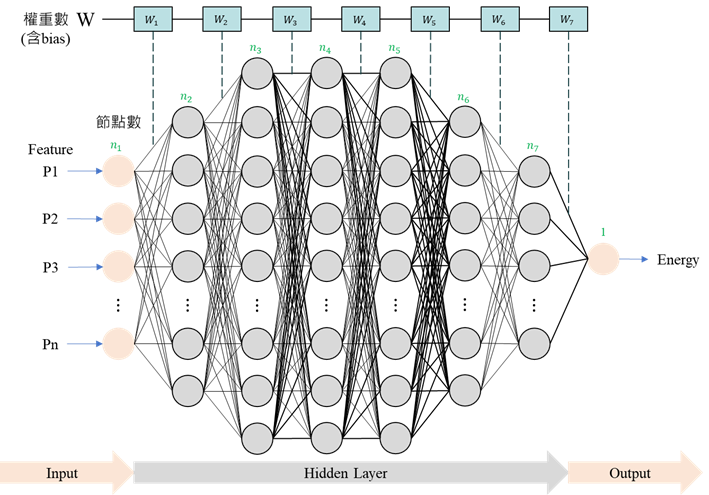

(3) Prediction Model Construction

A Deep Neural Network (DNN) is used due to its ability to handle complex, high-dimensional data.

-

Architecture: Includes multiple hidden layers, neurons, and activation functions (ReLU, Sigmoid).

-

Process: The model uses forward propagation for output and backpropagation with optimizers (SGD or Adam) to update parameters.

-

Prevention: Regularization (L2 or Dropout) prevents overfitting, while validation sets monitor performance.

|

III. Analysis Results

The study used a "Benz Mold" as the test subject to evaluate surface roughness and contour accuracy on a CNC milling machine. The primary goal was to predict total electricity consumption.

-

Sensors: Total power, three-axis motors (X, Y, Z), spindle, and cutting oil motor.

-

Configuration: 7–10 hidden layers; 8:2 ratio for training and testing sets.

-

Accuracy: Measured by Mean Squared Error (MSE).

The model achieved a prediction error of 2.02% on training data and 1.70% on validation data (see Table 1). Accuracy is expected to improve as dataset sizes increase.

Table 1: Energy Consumption Model Analysis and Validation Results

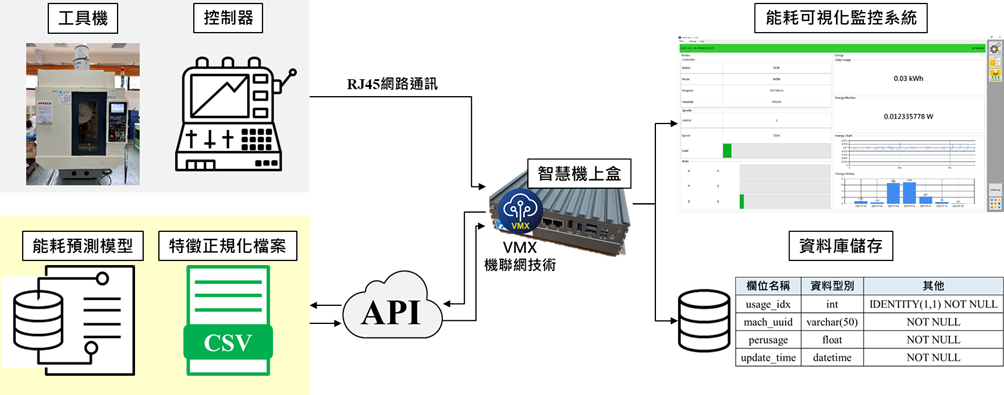

(1) Online Energy Monitoring

Real-time IIoT data is transmitted via RJ45 to the Intelligent Edge Box. The system calls the prediction model via Web-API to generate instant energy results. Visualized data helps operators adjust parameters to optimize energy use, while a Relational Database (RDBMS) records historical data for long-term trend analysis.

(2) Application Case: Stamping Equipment

This technology was applied to stamping equipment to solve the lack of real-time monitoring and difficulty in tracking carbon footprints. By installing sensors and using AI modeling, the system achieved errors of 1.27% (modeling) and 2.53% (validation).

-

Benefits: Optimized machining parameters to reduce waste and provided reliable data for carbon footprint reports, helping companies meet international sustainability requirements.

IV. Conclusion

This research successfully developed an AI-based energy prediction technology for machine tools with an error rate of less than 3%. The model is highly adaptable and can be optimized through expanded datasets or different training methods (e.g., cross-validation).

Future Outlook:

-

Expansion: Extend to peripheral systems (compressed air, chip removal) for a comprehensive carbon footprint.

|

-

Industrialization: Develop a Graphical User Interface (GUI) to lower the technical barrier, allowing enterprises to perform energy monitoring and modeling through simple steps. This will facilitate the practical implementation of smart manufacturing and sustainable development.

|

References

-

Breiman, L. (2001). Random forests. Machine learning, 45(1), 5-32.

-

Schmidhuber, J. (2015). Deep learning in neural networks: An overview. Neural networks, 61, 85-117.