Five-Axis Digital Twin Platform for Cyber-Physical System Machine Tool

In response to the dual transformation of machine tool digitalization and green manufacturing, most domestic companies integrate value-added digital twin solutions from major European and Japanese industrial control manufacturers. However, developing proprietary value-added features is difficult due to the closed nature of these digital twin platforms.

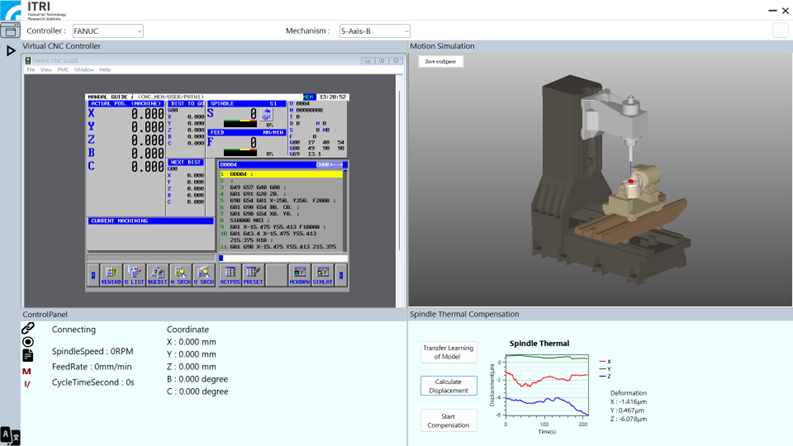

The Industrial Technology Research Institute (ITRI) has developed an open-architecture cyber-physical digital twin platform for 5-axis machine tools. It incorporates various digital twin models, including multi-brand Numerical Control (NC) simulators, 3D motion simulation and collision checking for 5-axis machine tools, AI spindle thermal displacement prediction, AI parameter tuning for servo drives, and mechatronic transmission and structural dynamics models. Standard communication networking and synchronized motion optimization are performed with the physical 5-axis machine tool, making the virtual machine tool's operation closer to the real machine, thus achieving more accurate workpiece prediction results.

Virtual Machine Tool Digital Twin Platform

The core functions of the Virtual Machine Tool Digital Twin Platform are the NC Simulator and the Multi-Axis Virtual Machine Tool Kinematics Model. After the processing program is interpreted by the NC Simulator, the machining coordinates are obtained. The platform reads these coordinates to slave the virtual machine tool kinematics model, achieving machining simulation to verify or optimize the processing program.

The adoption of digital twin technology allows for complete virtual simulation before machining, enabling virtual commissioning and precise simulation during the product development phase of the machine tool, and providing estimated product machining accuracy services. This is expected to reduce the production of defective parts and avoid material waste caused by repeated machining.

The Virtual Machine Tool Digital Twin Platform offers several digital twin modules, including the Virtual Machine Tool Kinematics Model, Multi-Brand NC Simulator, 3D Collision and Interference Checking, Mechatronics Integration, and AI Spindle Thermal Displacement Prediction and Compensation.

The platform can connect to the machine tool using customized communication protocols based on commercial controllers from Japan and Germany (including domestic PC-based controllers). It can also achieve Hardware-in-the-loop (HIL) synchronized connection with the actual controller based on the industrial standard OPC UA, reading machining program coordinates from the virtual or real controller and importing these motion coordinates into the 5-axis virtual machine tool kinematics configuration module. This enables 5-axis full-machine testing and 5-axis machining simulation with the 3D model linked to the NC [1], [2].

|

|

Through the Virtual Machine Tool Digital Twin Platform, users can pre-test the complex motion behavior of the machine tool and perform machining simulations. This significantly reduces the commissioning time for the actual machine tool and electrical control system, enables prediction of machining time and estimation of machining accuracy, thereby realizing precision manufacturing.

By establishing a collaborative system of digital twin modules for the controller, PLC, servo dynamics, and thermal deformation compensation, and developing an Energy Consumption Assistance Calculation Module for machine tool design, the platform uses data-driven approaches combined with a digital twin energy consumption prediction model. It collects energy consumption data and integrates the various digital twin modules for collaboration, optimizing machining efficiency, reducing energy consumption, and improving cost control and quotation accuracy.

Virtual Machine Tool Kinematics Digital Twin Module

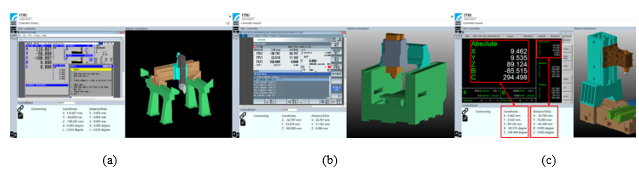

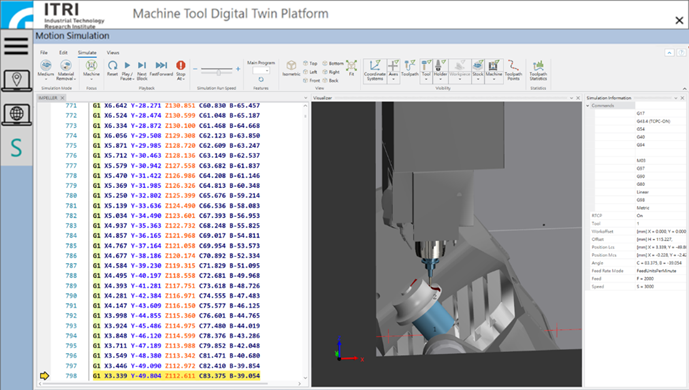

The Virtual Machine Tool Kinematics Digital Twin Module simulates the actual motion process of the machine tool, including spindle rotation, table movement, and tool feeding. The motion process is displayed on the platform interface as a visualized 3D model in real-time or accelerated time, allowing users to observe and adjust the details during machining.

The simulation process displays the interaction between the tool and the workpiece, showing the material removal process, allowing users to intuitively see the cutting process and the final product shape, while also checking for issues like overcutting, collision, overtravel, or other interferences.

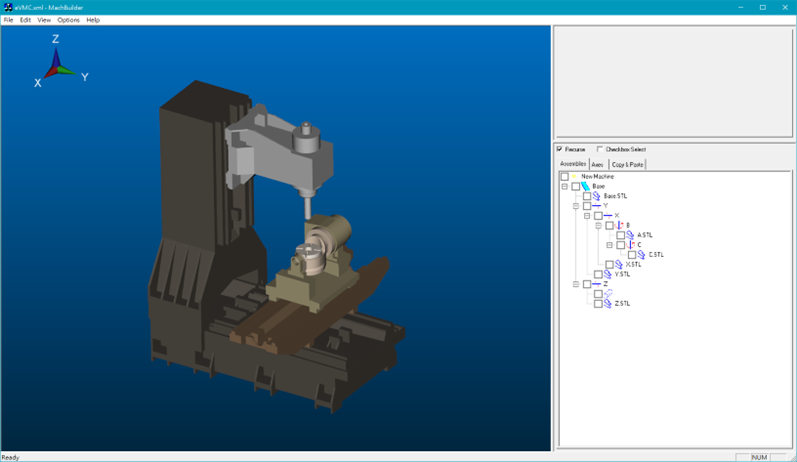

To visualize the 5-axis machining simulation process, the Virtual Machine Tool Kinematics Digital Twin Module can display the operation of different machine tool configurations. The 3D models are constructed from machine part STL (STereoLithography) file formats. The multi-axis machine tool kinematic chain assemblies are composed of moving parts such as the column, spindle head, machine body (including base), worktable, and linear guide saddle components.

|

The establishment of the kinematic chain must align with the actual machining process of the machine tool, considering the interrelationships of the machine tool axes' motion directions, machining travel range, tool growth direction, supported tool types (end mill, ball end mill), workpiece position, material production type (block, cylinder), the original position of each moving axis, and the motion method (linear or rotary). Once the kinematic chain is established, the tree diagram on the right side, as shown in Figure 2, indicates the dependency relationships between the models and axes [3]. The Virtual Machine Tool Digital Twin Platform currently supports 3 types of orthogonal 5-axis machine tools (trunnion table type, swivel head type, hybrid type) and 1 type of hybrid non-orthogonal 5-axis machine tool for 3D motion simulation.

|

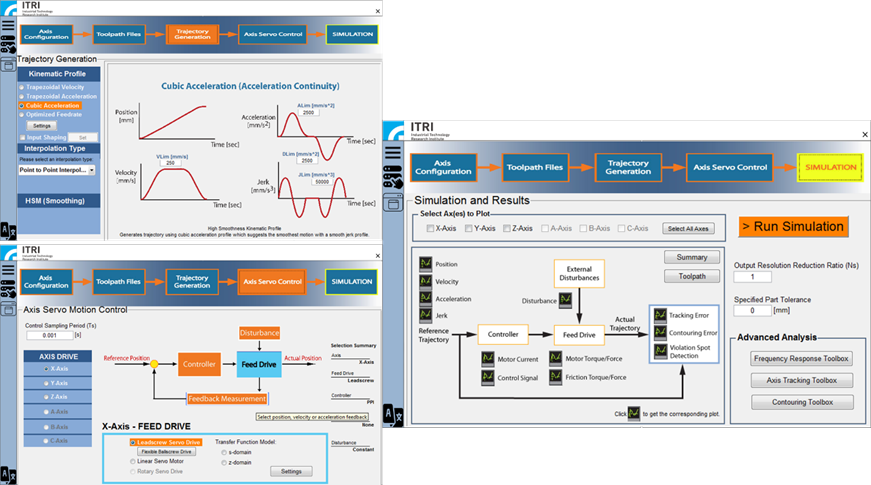

NC Simulator Digital Twin Module

ITRI's Virtual Machine Tool Digital Twin Platform includes the development of an NC Kernel Digital Twin Module. The Motion Generation Unit provides settings for point-to-point and curve position/velocity/acceleration/Jerk. The Axis Servo Control Unit offers a servo feed rigid-body dynamics model and a selection of various control laws (e.g., PID control, Lead-Lag control, Zero Phase Tracking Error control, Sliding Mode control, etc.). The Analysis Unit provides results such as frequency domain response, axis tracking, and contour error, as shown in Figure 4.

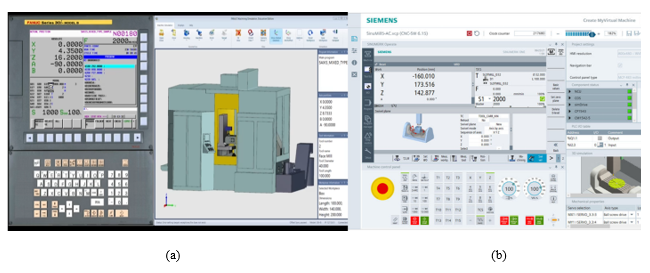

Digital twin systems currently used by domestic machine tool companies are commonly developed by major controller manufacturers, such as FANUC (Japanese) or SIEMENS (European), for example, CNC Guide 2 (Figure 5(a)) [4] and SIEMENS CMVM (Figure 5(b)) [5]. These systems integrate their own NC simulators and machining motion simulation software, providing machine tool and machining simulation functions that allow users to predict machine tool motion, tool paths, and machining results before actual machining.

|

ITRI's Digital Twin Platform also integrates multi-brand NC simulators (such as SIEMENS and HEIDENHAIN from Europe, FANUC and MITSUBISHI from Japan, and domestic PC-Based Syntec, etc.) for users to select the controller brand, including FANUC NC Guide (Figure 6(a)), SIEMENS SinuTrain (Figure 6(b)), and Syntec Dipole Server and CNC Monitor (Figure 6(c)). It uses their respective connection mechanisms to stream data: FANUC uses the Focas library [6], SIEMENS uses a Client API based on the OPC UA architecture [7], and Syntec uses its self-developed RemoteCNC API. The platform's IoT information collection function is compatible with different controllers and is not limited to a specific brand.

|

AI Transfer Learning Spindle Thermal Displacement Prediction and Compensation Digital Twin Module

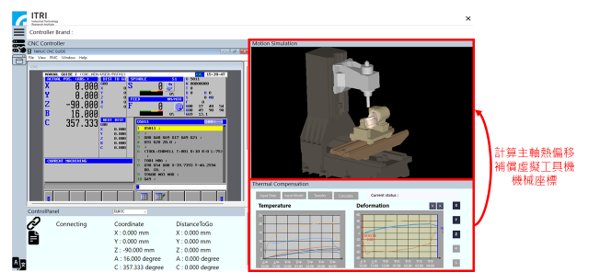

In simulating machining tasks, the final workpiece shape is determined by Boolean operations between the tool and workpiece models during kinematic motion. However, typical digital twin platforms only consider kinematics during machining simulation, assuming that the tool or workpiece simply moves according to the command coordinates sent by the controller. Physical effects such as thermal displacement, cutting mechanics, and friction are usually ignored. To improve simulation accuracy in order to adjust machine parameters and reduce actual machining errors, this digital twin platform calculates the errors caused by these dynamic characteristics through a Displacement Prediction Module and compensates them into the virtual machine tool machining coordinates.

Thermal error is the most significant factor affecting machining accuracy, accounting for 40% to 70% of the total error [8]. The Spindle Thermal Rise Module collects machine tool temperature and displacement information to establish an AI model. It then uses the temperature data acquired by sensors to estimate the thermal displacement error that will occur during machining. This error is compensated into the Virtual Machine Tool Kinematics Module via the Virtual Machine Tool Digital Twin Platform, allowing for a more accurate simulation of the machine tool's machining behavior, improving machining efficiency, and achieving energy savings and carbon reduction. Figure 7 shows the thermal rise error compensation mechanism within the platform.

[Figure 7: Communication Mechanism between AI Spindle Thermal Displacement Prediction Digital Model and Virtual Machine Tool Digital Twin Platform]

Figure 7. Communication Mechanism between AI Spindle Thermal Displacement Prediction Model and Virtual Machine Tool Digital Twin Platform |

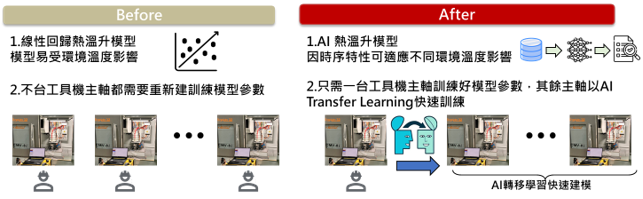

When a machine tool with the same configuration is equipped with a spindle of a different rotational speed, the entire process—re-collecting training data to train the spindle thermal rise model, testing the model, predicting the thermal error, and then performing machining verification—traditionally takes about two to three weeks. The spindle thermal rise model in ITRI's Digital Twin Platform uses Transfer Learning. When switching to a different spindle speed, rapid modeling can be achieved with a relatively small amount of experimental data. The pre-trained model establishment process involves: (1) Experimental data collection for different spindle speeds; (2) Establishing multiple AI spindle thermal rise models to determine the pre-trained model; (3) Training and testing the transfer learning; and (4) Compensation verification. Figure 8 compares the transfer learning AI spindle thermal rise model with traditional compensation methods.

[Figure 8: Training Process for Transfer Learning AI Spindle Thermal Displacement Digital Model]

|

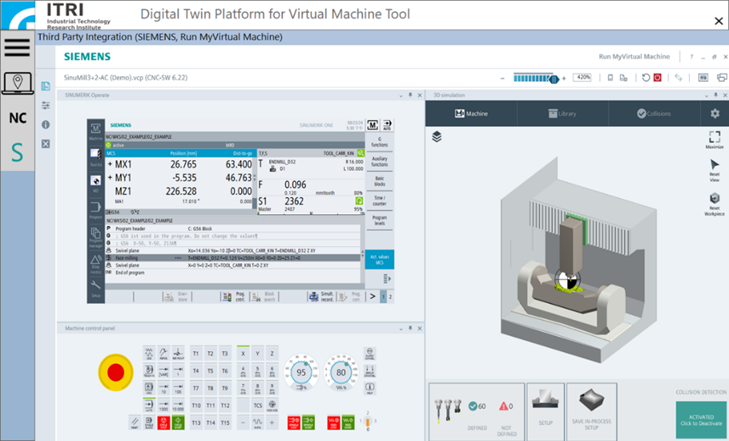

Third-Party Value-Added Software Integration Module - SIEMENS RMVM/CMVM

The SIEMENS RMVM [9] digital twin software platform integrates a series of functions, including the Sinumerik One NC simulator, 3D machine kinematics motion simulation, and PLC I/O input modules. ITRI's Virtual Machine Tool Digital Twin Platform integrates the RMVM software, allowing for virtual machine development, virtual machining simulation, and prediction of machining time and quality based on SIEMENS industrial control systems. In the future, the digital twin modules developed by ITRI can also be deployed to the SIEMENS Xcelerator to provide a cloud-based digital twin solution for machine tools.

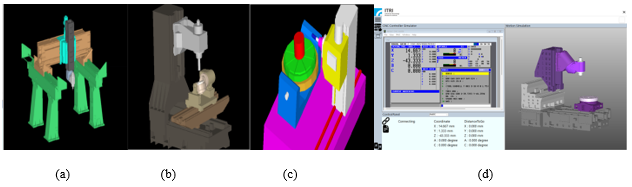

|

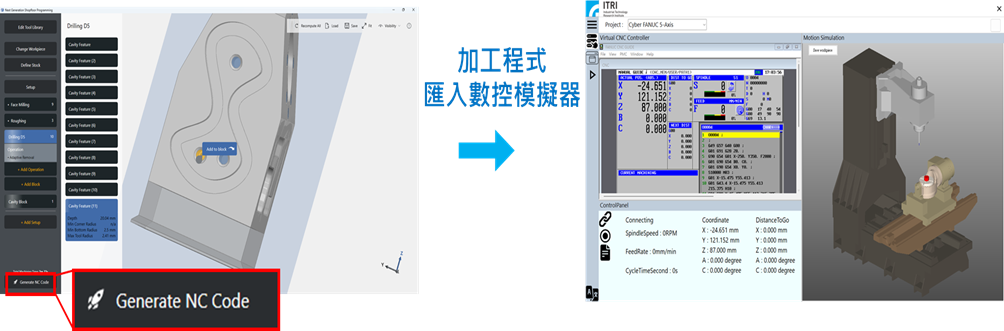

Third-Party Software Integration Module - CAMonMachine

ITRI's 5-axis machine tool digital twin platform combines with ModuleWorks for CAMonMachine value-added development. It can be embedded on commercial controller IPCs (such as FANUC and SIEMENS). Users only need to import the workpiece 3D file, select part features in the 3D geometry (such as planes, grooves, holes, channels, cavities, etc.), and define the machining process to automatically generate 3-axis or 5-axis NC programs.

The ModuleWorks-developed 3D machine tool motion simulation software, NcEditor [10], can use the imported machining program and user-defined virtual machine tool motion configuration to achieve machining simulation and collision prediction functionality. The platform can read the machining program directly (without controller interpretation) for machine kinematics motion simulation, providing users with a more lightweight method for program verification. Alternatively, it can use the multi-brand NC simulators within ITRI's digital twin platform to perform interpolated motion before 3D machine tool motion simulation, offering users a more accurate machining verification method.

|

|

Conclusion

ITRI has developed a domestic 5-axis machine tool digital twin platform. It features the development of various digital twin models, including virtual machine tool program code, machine kinematics, cutting mechanics simulation, collision checking, AI spindle thermal displacement prediction and compensation, NC simulator, structural dynamics, and transmission system friction and vibration. This platform assists manufacturers in providing customers with estimated machining time services before accepting orders, accelerates on-site commissioning procedures, and integrates multi-brand commercial controllers and European third-party value-added software to expand the machine tool industry ecosystem and assist Taiwanese machine tool enterprises with digital transformation.

Acknowledgement

We sincerely thank the Department of Industrial Technology (DoIT) of the Ministry of Economic Affairs for supporting the Key Project for Green Smart Machine Tools - Virtual Machine Tool Digital Twin Platform (Q368C11100), which enabled the successful execution of this project.

Referance

[1]李建毅、莊佳瑾、黃少谷,五軸工具機數位雙生平台技術,機械工業雜誌,500期,pp. 14-21,2024.

[2]李建毅、莊佳瑾、黃少谷,虛擬工具機數位雙生平台,機械工業雜誌,488期,pp. 12-18,2023.

[3]MachineWorks

[4]FANUC, CNC Guide

[5]SIEMENS, SinuTrain for SINUMERIK Operate

[6]FANUC, “FOCAS Library”, FANUC, https://www.fanuc.eu/de/en/cnc/development-software/focas-development-libraries, accessed Aug. 2024

[7]OPC Foundation, “OPC Foundation”, OPC Foundation, https://opcfoundation.org/, accessed Aug. 2024

[8] Ramesh, R., M. A. Mannan, and A. N. Poo. "Error compensation in machine tools—a review: Part II: thermal errors." International Journal of Machine Tools and Manufacture 40.9 (2000): 1257-1284.

[9]SIEMENS, Run MyVirtual Machine

[10]ModuleWorks