Smart Cutting Path Optimization Technology

Energy-Saving Technology for Machine Tools: Enhancing Competitiveness and Addressing Dual Transformation

Taiwan's machine tool industry, impacted by the depreciation of the Japanese Yen, faces price competition from both Japan and China. To overcome these challenges, domestic manufacturers must enhance the added functionality of their equipment and boost market competitiveness.

The escalating issue of global climate change is driving countries to pursue Net-Zero Emissions by 2050, forcing companies to demand carbon reduction efforts across their supply chains. This makes energy-saving technology a critical competitive factor. Reducing energy consumption has become a key objective in the metal processing sector, requiring machine tool suppliers to integrate add-on software to help customers achieve carbon reduction goals. Consequently, the development of energy-saving technologies specifically tailored for machine tools is vital for future competitiveness.

Path Analysis Technology

Before establishing an energy consumption model for machine tool servo axes, it is necessary to analyze the travel distance of each axis. This begins by interpreting the NC program to obtain the machining path, which is then used to calculate the travel distance of each machine axis. This data serves as the basis for subsequent model training and optimal parameter calculation. By interpreting the machining path from the NC program and coordinating it with the machine tool's inverse kinematics transformation, the change in travel distance for each axis at different rotation angles is recorded. Ultimately, this allows for the calculation of the movement ratio that results in the lowest energy consumption during power calculation.

Power Consumption Calculation

Modern machine tools are equipped with drivers that support the EtherCAT communication format. Therefore, during data acquisition, driver signals can be obtained via a network cable, integrated by the controller, and then transmitted back.

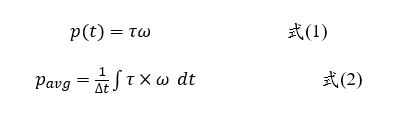

The relationship between motor torque and speed commands, as shown in Equations (1) and (2), allows for the calculation of power change for each axis, where τ is torque, 、ω is angular velocity, and p is power.

This method eliminates the need for installing an additional power meter, offering a cost advantage over traditional methods while meeting the requirement to differentiate energy consumption changes across individual axes.

Establishing the Servo Axis Energy Consumption Model

Neural network technology is widely applied in the industrial sector, primarily because of its ability to establish complex non-linear models. This study utilizes a neural network architecture to establish the energy consumption model for machine tool servo axes.

Since this model employs supervised learning, corresponding input and output data must first be collected for model training. Therefore, this study uses the Full Factorial Design method, incorporating factors that influence machining energy consumption into the experiment. We plan for 3 factors—machining path, feed rate, and spindle speed—each divided into 5 levels, and design 3 response variables: energy consumption for the X-axis, Y-axis, and spindle. Machining is performed under the same conditions for the tool, cutting depth, and material, recording the energy consumption data changes under different conditions for subsequent model training.

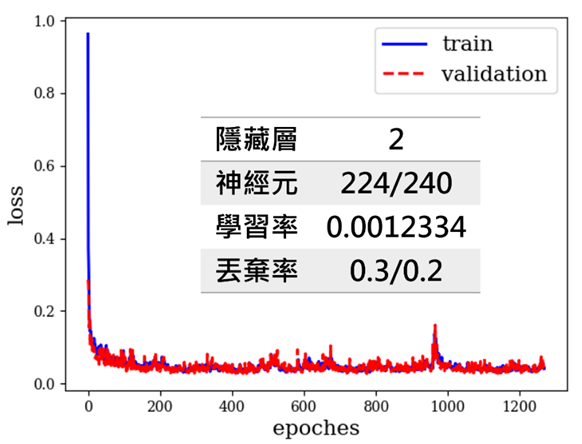

After completing the full factorial experiment and collecting the machine tool energy consumption data, a neural network model is established. Before training the model, the data must be normalized [1]. The feasibility of the experimental data is then assessed using t-SNE visualization. After data preparation, the neural network model is built, and the HyperBand hyperparameter optimization algorithm [2][3][4] is used to calculate the optimal number of hidden layers, number of neurons, learning rate, and dropout rate.

The calculation yielded the following optimal hyperparameters: 2 hidden layers, 224/240 neurons, a dropout rate of 0.3/0.2, and a learning rate of 0.0012334. Finally, the neural network model is trained using the parameters calculated by HyperBand until convergence, as shown in Figure 1.

Figure 1: Training Results and Parameters

Optimization of Low Energy Consumption Parameters

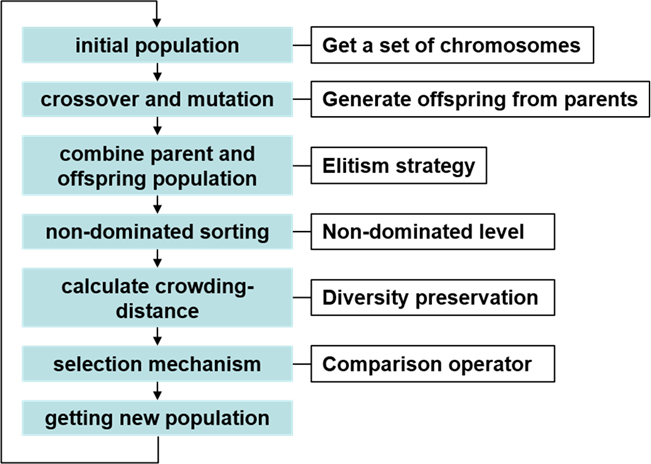

This study uses the Non-dominated Sorting Genetic Algorithm II (NSGA-II) to calculate the optimal parameters. Figure 2 shows the flowchart for the NSGA-II non-dominated sorting genetic algorithm.

Figure 2: Non-dominated Sorting Genetic Algorithm

The completed NC path analysis technology and machine tool energy consumption model are integrated into the NSGA-II algorithm. The input parameters for the model are the distance required for each axis movement of the NC path, spindle speed, and feed rate. By defining the input parameter ranges, the optimal parameters can be calculated.

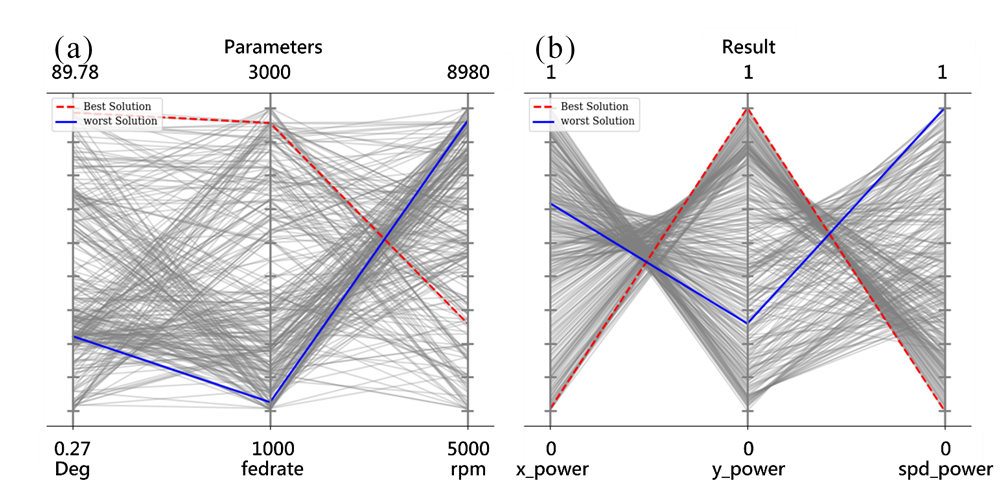

Taking the rotation angle range of 0 to 90 degrees, feed rate range of 1000 to 3000 mm/min, and spindle speed range of 5000 to 9000 rpm as an example, the calculation results are shown in Figure 3. Red indicates the input parameters resulting in the lowest energy consumption, and blue indicates the parameters resulting in the highest energy consumption, as shown in Figure 3 (a). Based on the best and worst input parameters, the corresponding output results are obtained: red represents low energy consumption, and blue represents high energy consumption, as shown in Figure 3 (b). The optimization results for planar machining show that the platform rotation angle required for the lowest energy consumption is 86 degrees, the feed rate is 3000 mm/min, and the spindle speed is 5223 rpm, as shown in Figure 3 (b).

Figure 3: Optimization Calculation Results (a) Input (b) Output

Machining Experiment

After completing the servo axis energy consumption model and the optimization calculation for low energy consumption parameters, the NC program can be parsed to calculate the travel distance of each axis, spindle speed, and feed rate, thereby deriving the machining parameters that result in the lowest energy consumption.

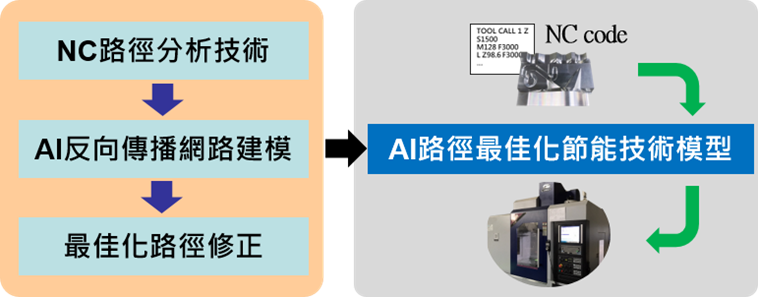

Finally, this technology was applied to the Kao Ming U250i 5-axis machine tool equipped with the ITRI M100 controller to verify the energy-saving technology of the machine tool. The implementation process is shown in Figure 4. First, the NC machining path is input into the NC path analysis technology to calculate the travel distance of each axis. Subsequently, the machine tool energy consumption model and the optimal parameter calculation function are used to determine the lowest-energy machining path and parameters, effectively improving the machine tool's energy efficiency and achieving the goal of energy saving and carbon reduction.

Figure 4: Energy-Saving Technology Flowchart

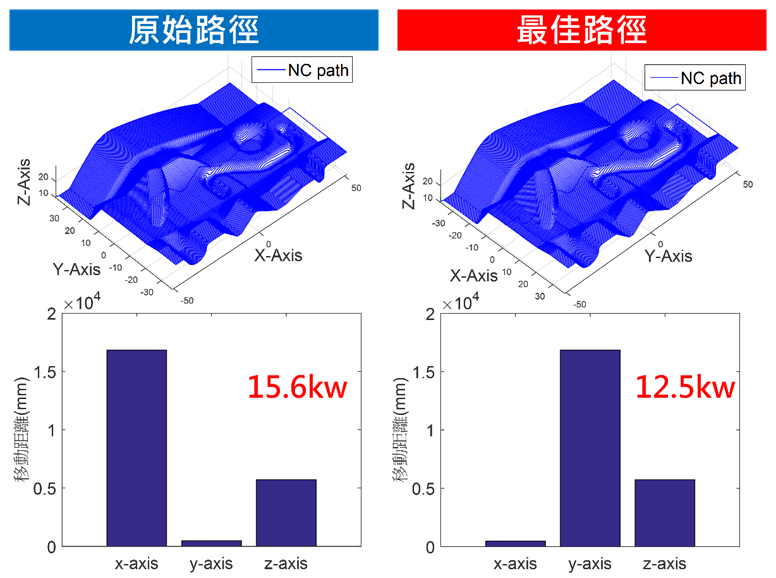

Analyzing the machining path and calculating the optimal parameters yielded a platform rotation of 86.62 circ, a feed rate of 2952 mm/min, and a spindle speed of $5004 \text{ rpm}$. The original machining program, which primarily used the X-axis for movement, was converted to primarily use the Y-axis. Comparing the power consumption of the optimal path with the original path, the original path consumed approximately $15.6kW of power, while the optimal path only consumed approximately $12.5 kW of power. This result indicates that the Y-axis movement of the Kao Ming U250i 5-axis machine tool currently in use consumes less power than the X-axis movement, as shown in Figure 5.

Figure 5: Verification Results

Conclusion

The technical verification demonstrated a significant energy-saving effect of the machine tool energy-saving technology. In the machining verification conducted on the Kao Ming U250i 5-axis machine tool equipped with the ITRI M100 controller, the power consumption of the original path was $15.6 \text{ kW}$. After calculating the optimal parameters and converting the path, the power consumption of the optimal path was reduced to $12.5 \text{ kW}$, resulting in a 30.5% saving in power consumption compared to the original path.

This research indicates that the proposed energy-saving technology can effectively reduce power consumption through Y-axis movement. For workpieces requiring large-scale production, adopting this energy-saving technology will significantly improve overall energy consumption, help domestic manufacturers provide value-added energy-saving technology, and thereby enhance industry competitiveness.