Digital Twin Workflow: From Theory to Practice in CNC Machining and Mechatronics

As the era of comprehensive digitalization arrives, the powerful tide of AI is sweeping across industries. In a rapidly evolving ecosystem and a volatile market environment, how has the manufacturing sector been impacted? Beyond the immediate challenge of labor shortages, there is an increasing demand for diverse new technologies and the need to control cost and quality with limited resources. How should industries confront these consecutive challenges?

Digital Twin technology bridges the gap between CAD/CAM and physical production. By using virtual programming to minimize the discrepancy between the virtual and real worlds, it brings revolutionary changes to CNC machining. This article explores the challenges faced by manufacturers and demonstrates how Digital Twin solutions enable safer, more efficient, and more economical CNC applications.

|

I. Challenges in CNC Machining

CNC users develop domain-specific solutions based on different industrial applications. In high-mix, low-volume production lines, frequent changes to parts, tools, and CNC programs are the norm. To maintain flexibility, operators often edit G-code directly on the machine. However, this increases the risk of errors in setup, tool selection, and programming, potentially leading to expensive rework or collisions.

The critical issue lies in the reliance on manual verification, such as "dry runs," which reduces equipment utilization and quality stability. Due to limited testing time, errors are often discovered only after machining, resulting in scrap, tool damage, or even machine breakdowns. Furthermore, a shortage of senior operators makes it difficult to provide comprehensive training for new staff without interrupting production.

|

Manufacturers in specific sectors—such as aerospace, heavy machinery, and medical devices—face different operational conditions. For them, process repeatability, precision, and strict quality standards are paramount. Unlike general production lines, their programming is workpiece-oriented, involving detailed offline work within CAD/CAM systems. For example, high-precision components like turbine blades often involve multi-axis machining of expensive materials like Titanium or Inconel. A single programming error can result in thousands of dollars in wasted material and severe production delays, necessitating optimized tool paths, precise cutting conditions, and real-time process monitoring.

Aerospace manufacturers must also comply with rigorous system engineering certifications (e.g., AS9100, NADCAP, FAA/EASA), requiring detailed documentation of the machining process. Meanwhile, automotive and medical manufacturers focused on mass production require extensive pre-development and pre-testing to ensure accuracy and efficiency. Therefore, machining simulation and analysis tools are vital for validating tool paths and ensuring optimal strategies.

|

II. Applications of Digital Twin in CNC Machining

Common Digital Twin applications allow CNC users to complete most development and validation tasks in a computer environment through virtual design and simulation of fixtures and tool selection. This saves time for process optimization and maximizes productivity.

|

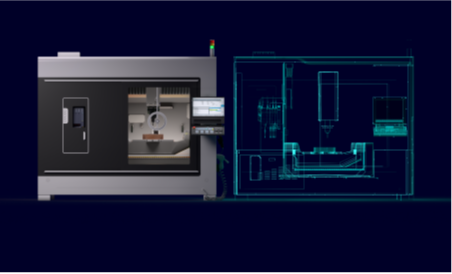

1:1 Motion Control and Mechanical Kinematic Chains

Digital Twin technology provides a precise simulation environment by integrating fine control and kinematic data. Machine tool builders can evaluate machine suitability and calculate cycle times virtually without occupying physical floor space. It also provides a safe, interactive training environment for operators to practice various scenarios, ensuring that when a machine arrives at the factory, programs and setups can be transferred immediately, avoiding equipment damage and the cost of physical prototypes.

|

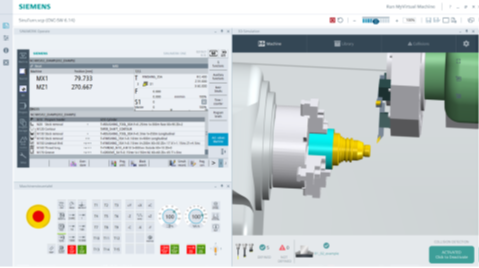

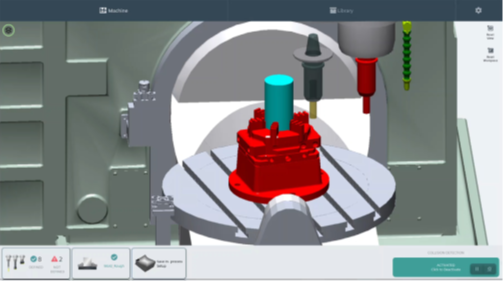

Virtual Process Verification

To achieve high fidelity between digital and actual machining, the Siemens SINUMERIK ONE interface offers Run MyVirtual Machine (RMVM)—a 1:1 digital twin of the CNC controller. With RMVM, users can execute NC code and verify tool movements, machine setups, and parameters in a simulated environment. This identifies errors before they reach the shop floor, reducing scrap and shortening setup times. RMVM also integrates fully with NX CAM, ensuring that the generated tool paths correspond exactly to the actual machining paths.

|

|

Real-Time Collision Avoidance

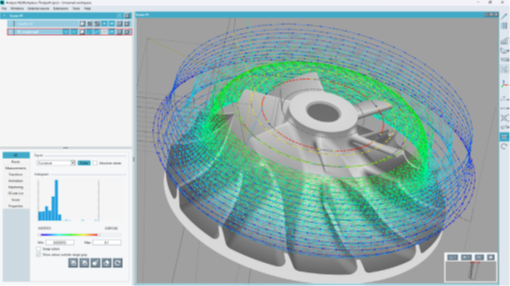

Users can utilize Protect MyMachine /3D Twin (PMM /3D Twin) to prevent collisions in real-time. It uses the same 3D engine as RMVM, ensuring consistent protection from simulation to operation. While RMVM prevents errors before machining, PMM /3D Twin monitors the actual process, automatically stopping the machine if a potential collision is detected. Additionally, Analyze MyWorkpiece /Toolpath (AMW /Toolpath) allows users to visualize and optimize tool paths to further improve production quality.

|

In practical applications, companies like PTG Holroyd Precision Ltd. (HG350-G gear grinder) and Maka Systems GmbH (PM270 CNC) have adopted the SINUMERIK ONE digital-native CNC system. By using these virtual tools, they have achieved reduced material waste, shorter manufacturing times, and immediate production readiness after virtual commissioning.

|

III. The Key to Precision in Mechatronic Design

Siemens' Digital Twin technology ensures that simulation results perfectly match actual machining behavior by integrating RMVM, PMM /3D Twin, and AMW /Toolpath.

|

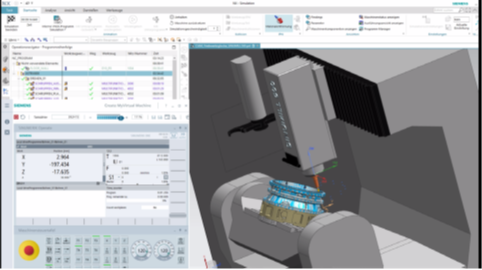

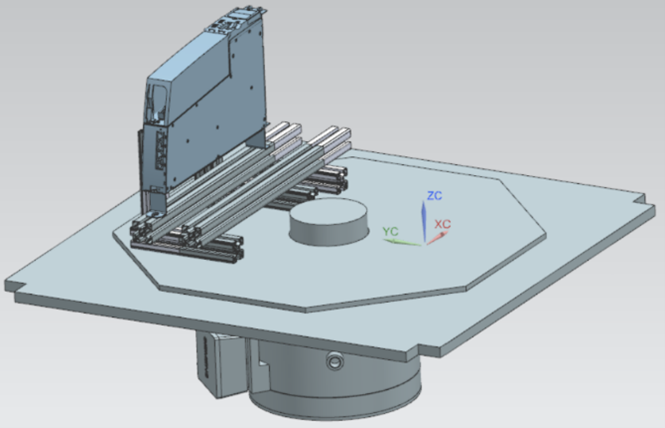

In mechatronics integration, Create MyVirtual Machine (CMVM) and Machine Concept Designer (MCD) are used for early-stage planning. After building a 3D mechanical model, engineers can perform motion simulation and mechatronic validation. This replaces physical prototype testing, significantly lowering development costs and shortening product cycles.

|

Servo Motor Selection

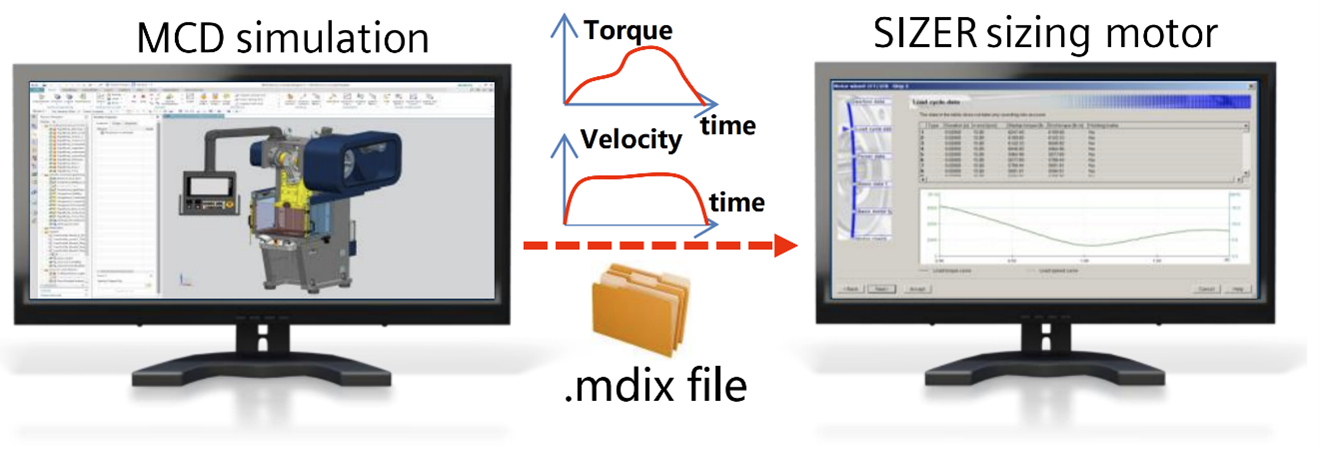

Choosing the right servo motor has traditionally been a challenge. Over-specification wastes energy and cost, while under-specification risks overheating or failure. With Digital Twin technology, engineers can find the optimal motor through simulation before physical manufacturing.

|

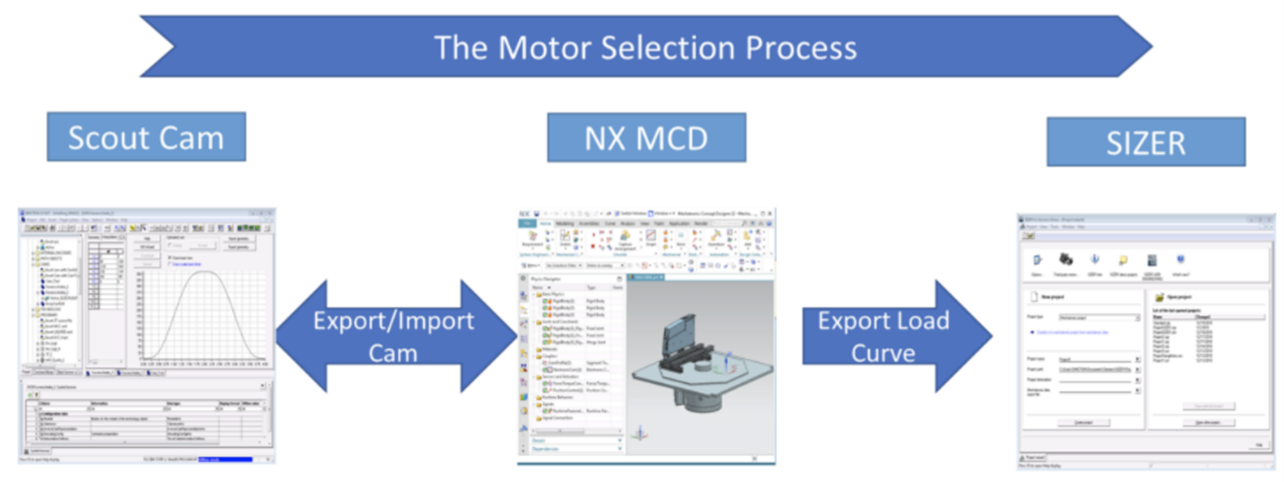

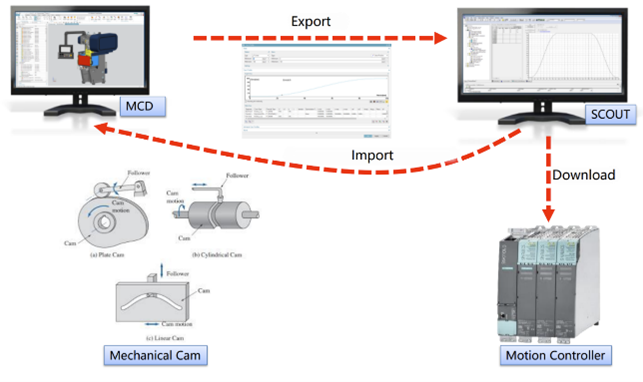

By combining SIMOTION SCOUT, NX MCD, and SIZER, a virtual twin with complete physical properties can be created for dynamic stress and load testing:

-

NX MCD: Uses a physics engine to calculate velocity and torque load curves.

-

SIMOTION SCOUT: Defines mechanical motion profiles (e.g., cam curves).

-

SIZER: Selects the appropriate motor, drive, and controller based on the load data.

|

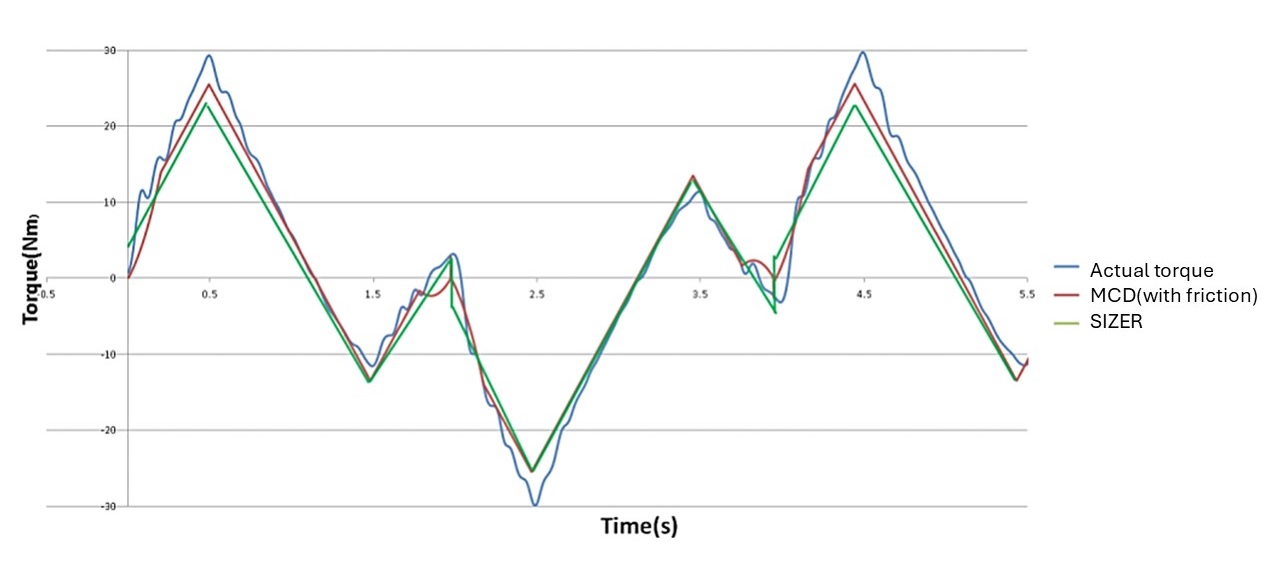

Case Study: Slip Ring Testing Machine

Using NX MCD, a 3D model of a slip ring tester was created, including a dynamic friction model. The simulation results for torque output (red line) almost perfectly overlapped with the actual measured values (blue line). This proves that the Digital Twin provides highly accurate predictions that traditional calculation methods cannot reach, allowing for the optimization of mechanical interference and inertia at the design stage.

|

|

|

-

Blue line: Torque measured from the actual machine.

-

Red line: Torque simulated by the Digital Twin (including friction model).

-

Green line: Torque simulated by the Digital Twin (excluding friction).

IV. Conclusion

In the current wave of digitalization and smart manufacturing, Digital Twin technology has become a pivotal force in driving innovation. It not only enhances simulation and monitoring but also creates a safe training environment, reducing risks and waste.

As the machine tool industry moves toward intelligence, the SINUMERIK system serves as a core gateway for AI integration. By combining sensor data, edge computing, and cloud platforms, machines can achieve autonomous adjustment and predictive maintenance. This transition accelerates the implementation of "Smart Machinery" and injects new momentum into high-end manufacturing and global competitiveness.