Introduction to the AI-Powered Solution Demonstration Site for the Machine Tool and Components Industry Ecosystem

In traditional mechanical manufacturing, the stages from product design to pilot production often require significant investment. Faced with international tariff fluctuations and cost pressures, shortening design and development cycles to reduce the cost of first-article sampling is key to enhancing competitiveness. Consequently, the government has mandated that research institutes open AI pilot production lines and training resources to enterprises. This initiative aims to accelerate the adoption of AI across all industries and promote AI talent cultivation policies. To meet product development needs, these pilot lines have been fully upgraded with new AI manufacturing equipment and application environments, supporting innovative product development across processes such as design, trial production, and quality inspection. Employees can operate smart machinery on-site and participate in practical training to deepen their understanding of AI and build essential skills. By validating trial production processes, companies can directly bring AI experience and technical modules back to their own operations for rapid replication.

The PMC Mission and the Digital Twin Core

The Precision Machinery Research and Development Center (PMC) is dedicated to passing down technical achievements in product development, inspection, and testing within Taiwan’s machine tool industry. Under the guidance and assistance of the Ministry of Economic Affairs (MOEA), PMC has established the "AI-Powered Solution Demonstration Site for the Machine Tool and Components Industry Ecosystem." Built on the core of Digital Twin technology, this site provides integrated high-quality process verification and equipment development services for the industry ecosystem.

The demonstration site serves both "Makers" and "Users" within the ecosystem:

-

Makers (Machine Tool Manufacturers): Focused on Product. Helping them rapidly design and manufacture customized, advanced, high-performance equipment and provide specialized services.

-

Users (Machine Tool End-Users): Focused on Production. Helping them shorten the processing time for high-quality workpieces required by various industries and providing testing services.

Core Value: Practical AI Application and Digital Twin Simulation

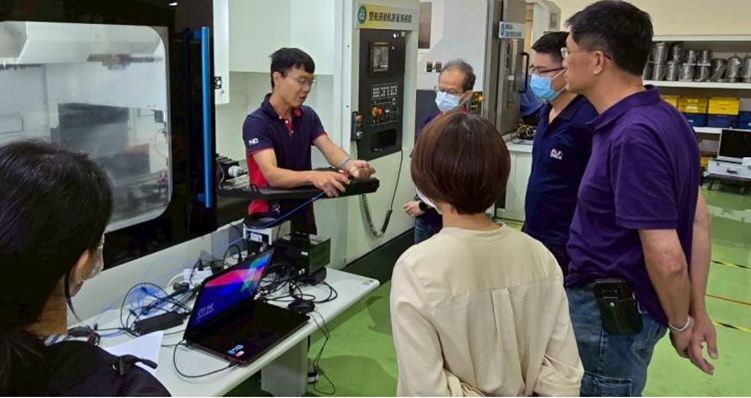

The core of the AI pilot production line is to allow the industry to apply AI equipment in actual trial production procedures. By experiencing the benefits of AI-integrated processes, participants gain a deep understanding of the potential of smart manufacturing.

The site utilizes a Digital Twin platform and design analysis simulation technology. In the early stages of development, accurate digital models can be established quickly. This allows R&D personnel to accurately predict designs, manufacturing procedures, and optimize product solutions in a virtual environment, significantly increasing the design success rate and reducing development costs.

Solutions Using Digital Twin for Pre-Evaluation:

-

Product (Machine Design Evaluation): Predict machine performance during the design phase. Trial production and verification begin only after performance standards are met.

-

Benefits: Improved R&D efficiency, enhanced machine performance, and lower development costs.

-

-

Production (Process Planning Evaluation): Predict process performance during the planning stage. Pilot production begins only after performance is confirmed.

-

Benefits: Improved machining precision, stable workpiece quality, and shortened manufacturing time.

-

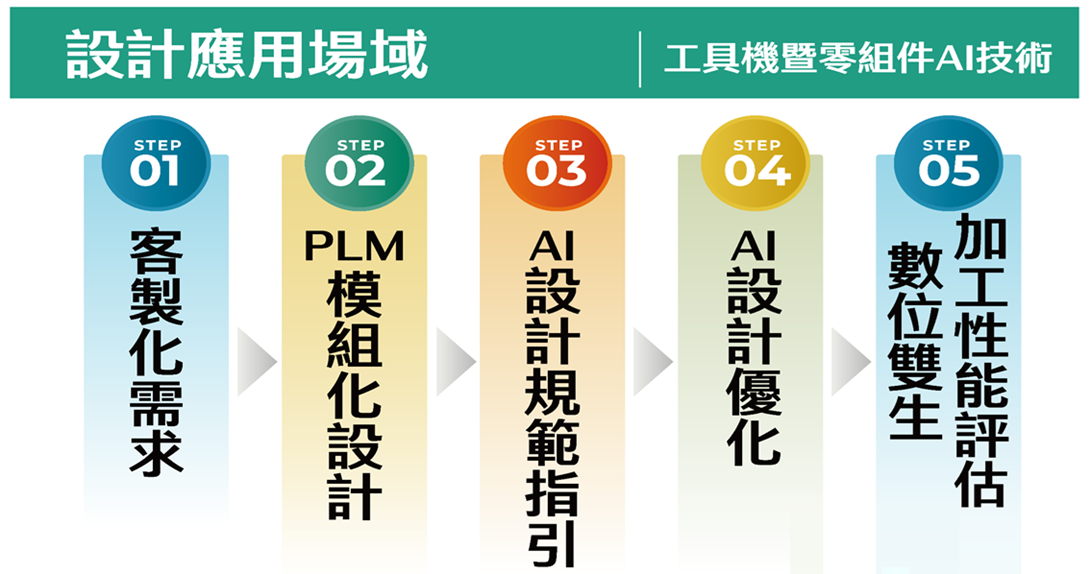

In the Product stage, the introduction of AI or Generative AI (GAI) provides design recommendations, performance evaluations, quality guidelines, assembly assistance, and anomaly diagnosis. In the Production stage, smart functions such as tool selection, machining performance evaluation, parameter optimization, multi-axis cutting, chatter analysis, accuracy compensation, and tool life prediction are provided to help businesses create efficient and stable machining processes.

PMC Site Service Items

1.Machine Tool and Component Design Services: End-users can use Digital Twin technology and CAD/CAM to plan machining parameters and select tools. Manufacturers can utilize design specifications combined with Digital Twin simulations for part selection and performance modeling to shorten development cycles.

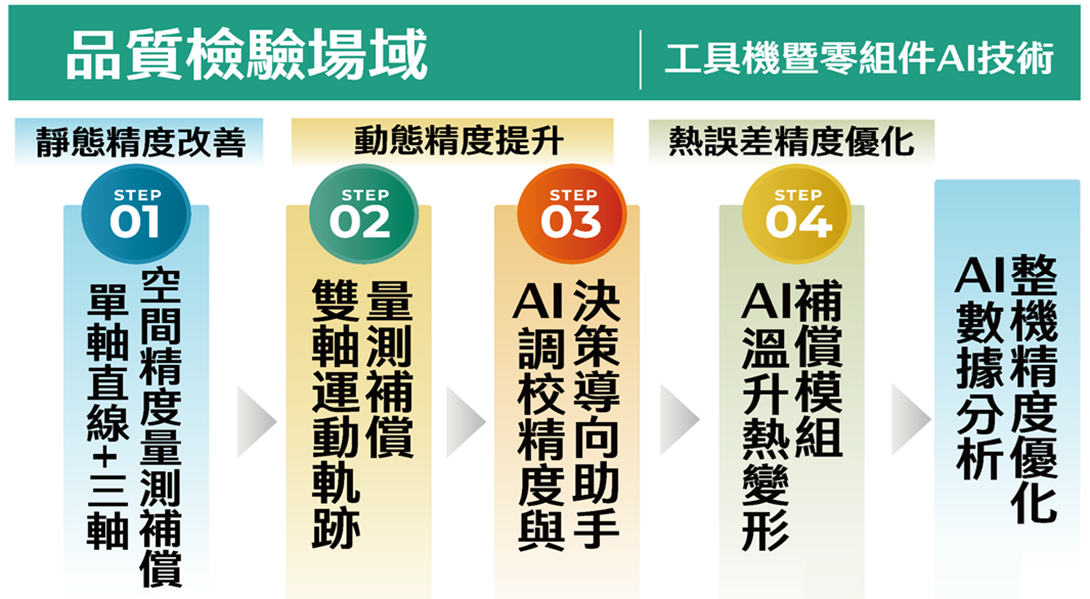

2.Machine Tool and Component Manufacturing Services: Through multi-axis machining applications, dynamic characteristic analysis, and chatter analysis, the site helps users optimize workpieces to achieve higher precision and quality. Manufacturers benefit from AI quality guidelines and expert systems for assembly accuracy and adjustment.

- Machine Tool and Component Quality Inspection Services: Users can utilize AI quality analysis to identify the root causes of anomalies. Manufacturers can use services like mechanical accuracy inspection and spindle health diagnostics, where AI analyzes inspection data to resolve design issues and improve product reliability.

4.AI Talent Training and Transformation Services: Companies can bring real-world floor problems to the site for collaborative problem-solving. Participants learn the complete AI deployment flow—from data collection and model building to application. This "learning by doing" approach helps build a technical database for future AI cultivation and accelerates digital transformation.

Featured AI Assistant Systems

Beyond hardware and Digital Twin platforms, the site provides several specialized software tools:

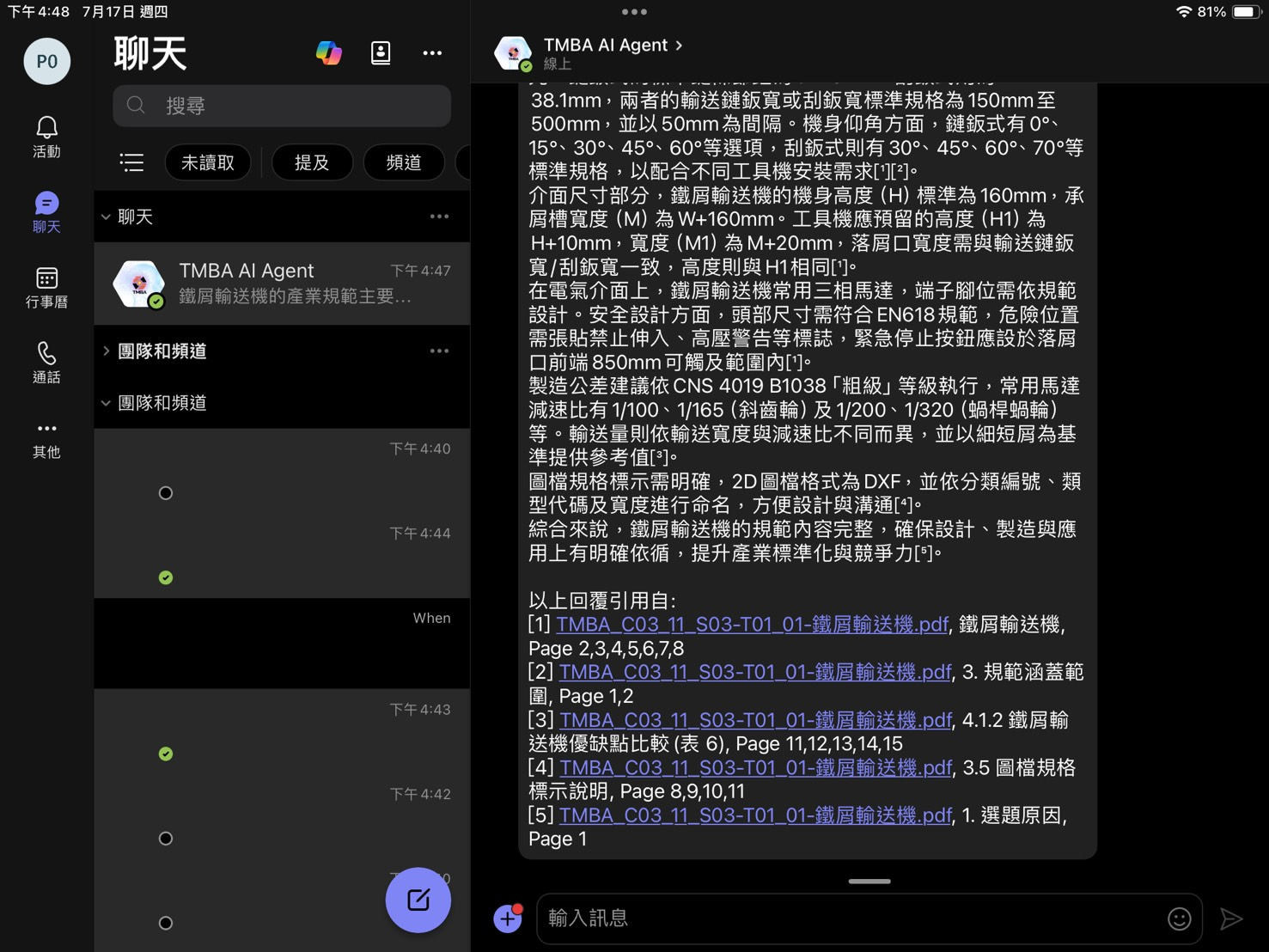

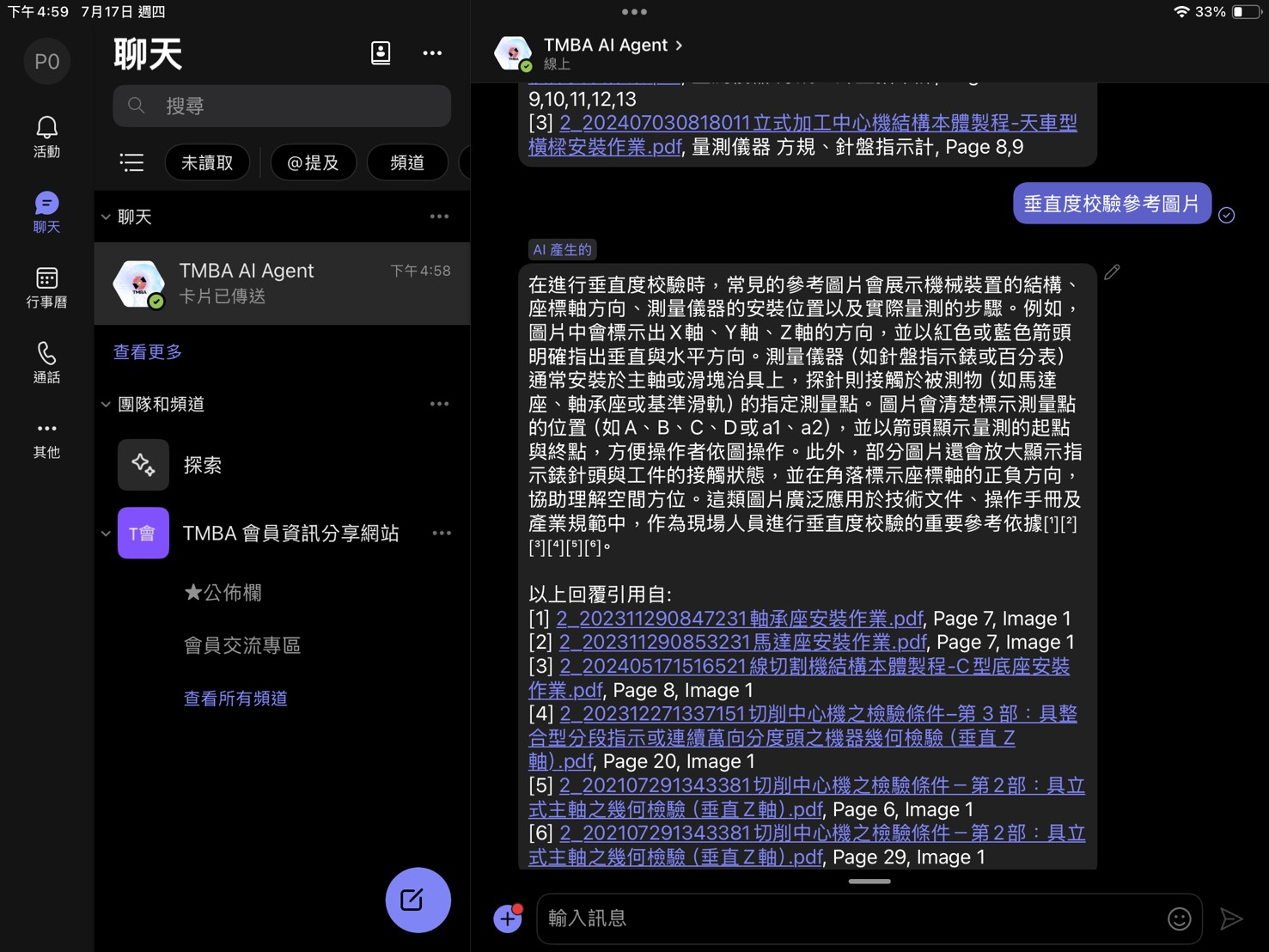

TMBA AI Agent (Teams App - Feb 2025):

Developed by the Taiwan Machine Tool & Accessory Builders’ Association (TMBA) using Microsoft Copilot Studio. It is trained on machine tool industry knowledge to analyze market trends and provide rapid queries for design and quality specification documents.

|

|

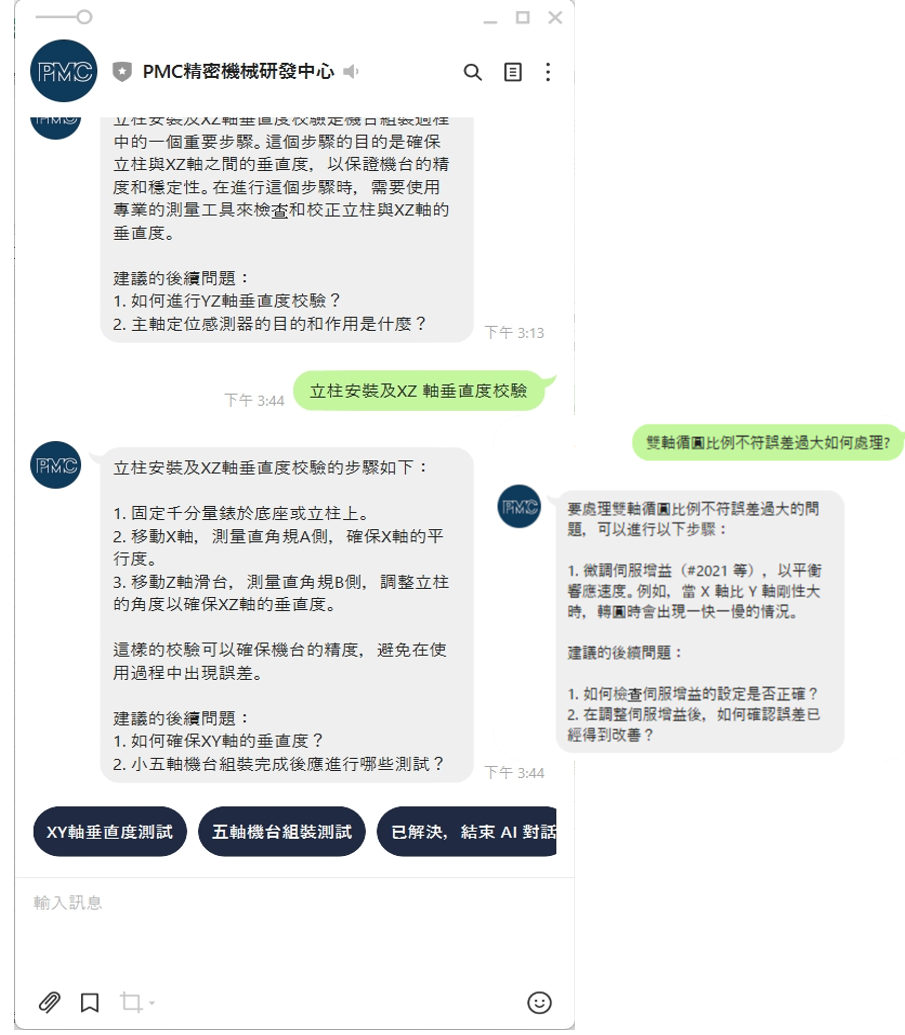

PMC "X GO!" Assembly Assistant (Line App - March 2025)

Developed by PMC using GPT-4o, this assistant integrates 30 years of assembly experience. It serves as an AI knowledge base for assembly SOPs and "master craftsman" secrets, providing 24/7 support for technicians on the shop floor.

|

Amon Tech AI Precision Tuning & Decision Assistant (Web App):

Developed by the team of Dr. Jue Wen-yuh from National Taiwan University, focusing on standardized Generative AI, smart precision measurement, IoT, AR, and decision-oriented tuning for 5-axis equipment.

By accumulating skills through hands-on practice, industry employees enhance their technical strength and transformation resilience. From shortening R&D cycles via virtual simulation to achieving "First Part Correct" rapid manufacturing through AI-optimized assembly and inspection, these technologies help the machine tool industry move toward zero-waste, high-efficiency smart manufacturing.