The Application of Lightweight Design for Green Machine Tool

By Industrial Technology Research Institute (ITRI), Intelligent Machinery Technology Center, Intelligent Manufacturing Technology Division, Intelligent Machine Technology Department

Chien-Chih Liao, Manager / Pei-Yin Chen, Deputy Manager / Hsiao-Chen Ho, Deputy Technical Manager / Jen-Chieh Wang, Section Chief

Introduction

With the European Union’s Carbon Border Adjustment Mechanism (CBAM) starting its trial phase in 2023 and the United States proposing the Clean Competition Act (CCA) in 2024, both initiatives aim to reduce imports of high-carbon products and promote domestic green industries through carbon taxes and emission restrictions. Taiwan’s machine tool industry relies heavily on exports, so these regulations will have profound impacts. Coupled with global leading companies announcing net-zero carbon timelines, driving green transformation in Taiwan’s machine tool supply chain has become an urgent issue.

The 2021 Machine Tool Industry White Paper emphasized exploring R&D innovation from the customer perspective, such as providing production energy solutions, process efficiency guarantees, lifecycle services, and energy-saving carbon reduction. Since both the use and manufacturing of machine tools involve carbon emissions, lightweight design can effectively reduce energy consumption and carbon emissions during machine operation, as well as lower emissions during manufacturing, achieving the goal of producing green machine tools.

ISO 14955 Green Machine Tools

International machine tool leader DMG MORI proposed three concrete measures for green transformation: Green MACHINE, Green MODE, and Green TECH.

- Green MACHINE aims to achieve carbon neutrality across the entire machine tool lifecycle—from raw material procurement to manufacturing, assembly, packaging, and transportation.

- Green MODE focuses on improving machining efficiency and reducing energy consumption through software optimization and low-energy components.

- Green TECH applies equipment to innovative green energy industries such as geothermal, wind power, fuel cells, and solar energy.

In Taiwan, the machine tool industry association has actively promoted green transformation, launching a green machine tool product evaluation in 2023 and adopting the theme “Dual-Axis Manufacturing, Sustainable Future” for the 2024 TIMTOS show, highlighting digital and green transformation goals.

ISO 14955 provides measurement standards for evaluating machine tool energy consumption and suggests methods to reduce it. According to ISO 14955-1, over 90% of carbon emissions in a machine tool’s lifecycle occur during machining, primarily from electricity consumed in metal cutting. Therefore, reducing energy consumption during operation is key to achieving green machine tools. Design strategies include structural geometry optimization, new materials, and energy-saving components, while application strategies involve machining optimization and intelligent energy control. This paper focuses on structural lightweight design methods to develop green machine tool design technologies.

Structural Geometry Optimization Techniques

Traditional machine tool structural improvements rely on engineers’ experience and manual parameter adjustments, which are time-consuming and may not yield optimal results. Optimization methods, based on mathematical theories, automatically search for better design variable combinations to find the best solution with minimal iterations, overcoming the drawbacks of trial-and-error approaches.

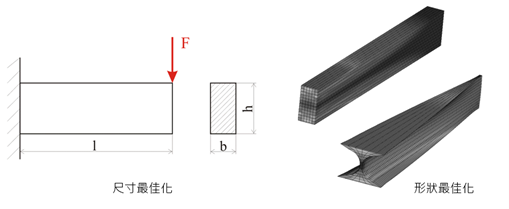

Conventional optimization includes size optimization and shape optimization (Figure 1).

|

- Size optimization adjusts geometric dimensions such as length, width, height, and thickness, aiming to minimize mass while meeting stress constraints.

- Shape optimization modifies node positions in finite element models to reduce stress concentrations by changing curvature, differing from size optimization.

Both require an initial design and only adjust features like ribs and holes without adding or removing major structural elements.

Topology Optimization Technology

Topology optimization automatically generates optimal structures using computational methods. Introduced in the late 1980s by Bendsøe and Kikuchi, the SIMP method later simplified design variables, making topology optimization the most effective structural optimization technique in the past 30 years. Initially adopted in aerospace and automotive industries for lightweight designs, it has recently been applied to machine tools.

In practice, topology optimization often addresses stiffness optimization under volume constraints. For example:

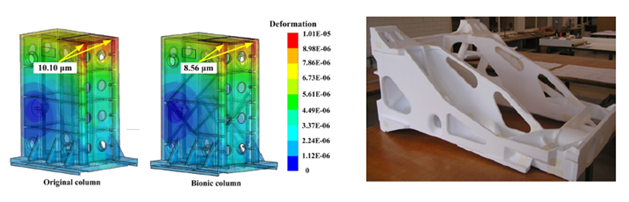

- Li and Hong applied topology optimization to a grinder column, reducing deformation by 23.6% and weight by 1.31%.

- P. Wagner demonstrated its use in machine tool design, emphasizing consideration of both static and dynamic stiffness to enhance cutting performance (Figure 2).

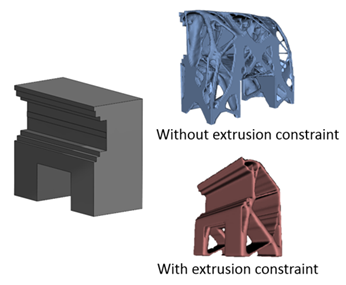

DMG showcased a topology-optimized machine structure at JIMTOF 2018 (Figure 3).

|

|

However, topology optimization often produces complex geometries with hollow or enclosed features, which may conflict with manufacturing constraints like milling or casting directions, increasing costs. Incorporating process constraints (e.g., extrusion direction) simplifies geometry and reduces costs while maintaining performance (Figure 4).

|

Practical Applications

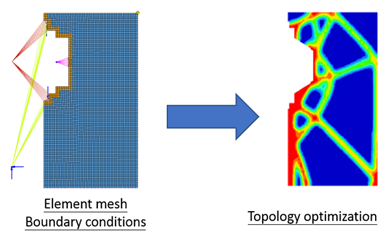

This study applied topology optimization with process constraints to machine tool structures. For example:

- A column structure was optimized under weight and cutting force constraints, identifying critical elements for retention (Figure 5).

|

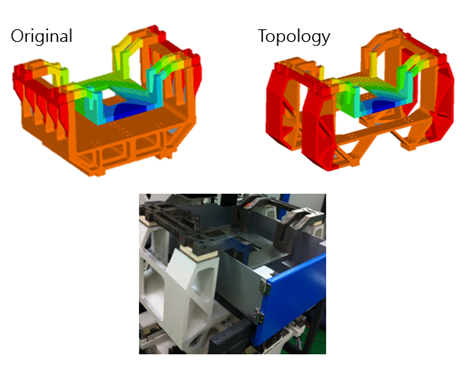

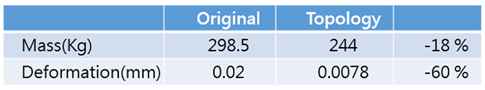

- A wire-cutting machine table optimized for static stiffness reduced weight by 18% and deformation by 60% (Figure 6, Table 1).

|

|

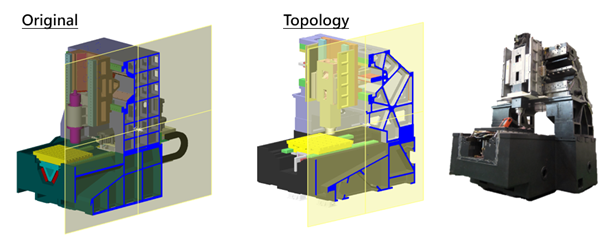

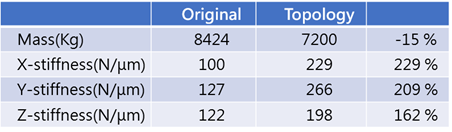

- A small gantry machining center optimized for stiffness achieved a 15% weight reduction (1,224 kg) and increased X/Y/Z-axis stiffness by 229%, 209%, and 162%, respectively (Figure 7, Table 2).

|

|

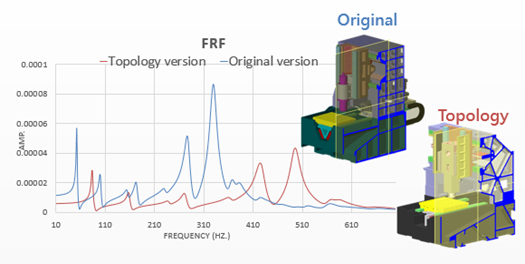

- Dynamic stiffness improved by over 50%, enhancing cutting capability (Figure 8).

|

Emerging Materials for Lightweight Design

Beyond geometry optimization, introducing advanced materials offers disruptive innovation. Hybrid structures combining composites and metals are gaining attention. The European DEMAT 29 project aims to reduce metal usage in machine tools by 50% with fully recyclable materials offering high stiffness and damping.

Although composite use in machine tools was previously limited by cost and technical challenges, recent advancements have enabled adoption. Examples include:

- Germany’s MAP integrating composites into machine structures (Figure 9).

- Czech CompoTech and EAGLE Lasere reducing gantry machine weight by 50%.

- FOOKE’s ENDURA® 700LINEAR using carbon fiber composites for headstock lightweighting, embedding sensors for structural health monitoring, and improving feed response and energy efficiency.

|

Conclusion

This paper demonstrates practical applications of lightweight design for green machine tools. ISO 14955 analysis shows that most carbon emissions come from electricity used during metal cutting. Reducing moving component weight lowers motor energy consumption and may allow smaller motors, further reducing energy use.

By integrating topology optimization with process constraints, lightweight structures achieve high stiffness and performance. Combined with advanced materials, these innovations enhance product value, support customization for high-end applications, and align with ISO green machine tool standards, maintaining Taiwan’s global competitiveness and promoting sustainable industry development.

Acknowledgment

We thank the Ministry of Economic Affairs for supporting the project “Development of Key Technologies for Green Intelligent Machine Tools – Design and Application Verification of Low-Energy Lightweight Structures” (Project No. P368C12100).

References

- ISO 14955, https://www.iso.org/standard/70035.html

- Bendsøe, M.P. and Kikuchi, N., Generating optimal topologies in structural design using a homogenization method. Computer Methods in Applied Mechanics and Engineering, 1988.

- Bendsøe, M.P., Optimal shape design as a material distribution problem. Structural Optimization, 1989.

- Zhou, M. and Rozvany, G.I.N., The COC algorithm, Part II: Topological, geometrical and generalized shape optimization. Computer Methods in Applied Mechanics and Engineering, 1991.

- Li, B., J. Hong, and Z. Liu, Stiffness design of machine tool structures by a biologically inspired topology optimization method. International Journal of Machine Tools and Manufacture, 2014.

- P. Wagner, Simulation in design of high-performance machine tools. HELLER GmbH