EMO Hannover 2025, Germany: On-site Observations and Trend Analysis

Ke-Chang Yao, Deputy Director; Chia-Jui Lee; Yu-Shan Sun

Precision Machinery Research & Development Center (PMC)

I. Abstract

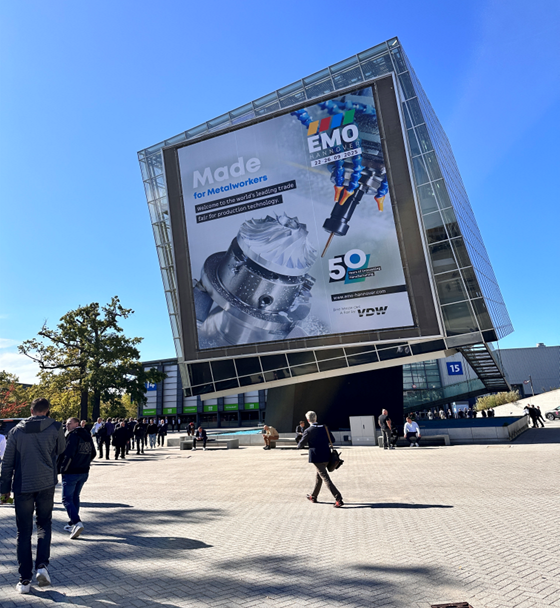

The EMO Hannover 2025 exhibition in Germany is one of the most influential international trade shows in the global machine tool industry. This edition marked the 50th anniversary of EMO, with the theme “Innovate Manufacturing.” The exhibition focused on forward-looking trends including automation technologies, artificial intelligence (AI) and digital transformation, green manufacturing, and process integration, showcasing the technological evolution and strategic adjustments of the global machine tool industry in response to emerging challenges.

Despite the historical significance of this edition, the overall exhibition scale reached a recent low, reflecting the structural downturn and weak market demand currently faced by the European machinery manufacturing sector. Several major manufacturers reduced their booth sizes or chose not to participate, indicating that the industry is at a critical stage of transformation and repositioning. Based on on-site visits and collected exhibition materials, this paper analyzes the dynamic trends and technical highlights presented by exhibitors from different countries and explores the challenges and opportunities facing the machine tool industry amid the waves of digitalization and sustainable development, providing reference points for industry development planning, technology deployment, and international market expansion.

II. Exhibition Trends

EMO (Exposition Mondiale de la Machine-Outil) was initiated and sponsored by the European Association of the Machine Tool Industries (CECIMO). Since its establishment in 1975, it has a history of fifty years (Figure 1). Positioned as the world’s largest machine tool exhibition with the most diverse exhibits and leading technological standards, EMO focuses on high-end application markets and has become one of the most representative and authoritative professional exhibitions in the global machine tool sector. Over the past half-century, EMO has established its leadership in global manufacturing technology and is widely regarded as a key barometer for observing the current status and future trends of the international machine tool industry.

Figure 1. Historical Review of the 50th Anniversary of EMO 2025 Hannover

EMO Hannover 2025 was grandly held from September 22 to 26, 2025 (Figure 2), with approximately 1,600 exhibitors from 45 countries and regions. The number of exhibitors by country is shown in Table 1.

Table 1. Number of Exhibitors by Country/Region at EMO Hannover 2025

| Country/Region | Exhibitors | Share |

|---|---|---|

| Germany | 470 | 30.09% |

| China | 327 | 20.93% |

| Italy | 144 | 9.22% |

| Taiwan | 125 | 8.00% |

| Switzerland | 76 | 4.87% |

| Japan | 52 | 3.33% |

| Türkiye | 46 | 2.94% |

| Spain | 45 | 2.88% |

| South Korea | 45 | 2.88% |

| India | 44 | 2.82% |

| United States | 29 | 1.86% |

| Czech Republic | 24 | 1.54% |

| France | 20 | 1.28% |

| Netherlands | 19 | 1.22% |

| United Kingdom | 14 | 0.90% |

| Austria | 13 | 0.83% |

| Canada | 9 | 0.58% |

| Sweden | 9 | 0.58% |

| Israel | 7 | 0.45% |

| Denmark | 5 | 0.32% |

| Brazil | 3 | 0.19% |

| Poland | 3 | 0.19% |

| Bulgaria | 3 | 0.19% |

| Mexico | 1 | 0.06% |

At EMO Hannover 2025, Germany and Italy remained the major European exhibiting countries, while China had the largest number of Asian exhibitors (20.93%). Taiwan participated with 125 companies, a decrease of 19 exhibitors compared to the previous edition. However, the number of components and accessories suppliers increased, reflecting a trend toward deeper supply chain integration and technological upgrading. The overall exhibition focus was on helping customers build flexible customized production lines and integrated solutions, reflecting the global machine tool industry’s move toward intelligent and sustainable manufacturing.

Exhibition Highlights

In addition to showcasing various advanced machining equipment, EMO 2025 also presented measuring instruments, cutting tools, molds, and key components, including hydraulic and pneumatic elements, and control systems. Due to the current downturn in the European manufacturing market, this edition opened only 12 exhibition halls, compared with 15 halls at EMO Hannover 2023.

A comprehensive review of the exhibition halls shows that this edition focused on integrating information and communication technologies (ICT) into machine tool manufacturing solutions to provide end users (such as aerospace and defense industries) with more comprehensive and convenient solutions. The show content focused heavily on future-oriented technologies such as automation, industrial robots, and intelligent inspection, fully demonstrating the manufacturing industry’s transition toward digitalization and sustainability. Exhibits covered metalworking, smart manufacturing, automation, AI applications, and sustainable technologies, as described below.

Theme 1: Strengthening Exchanges with the International Metalworking Industry

EMO is not only a technology exhibition platform but also offers forward-looking guidance through forums and networking events. During the exhibition, multiple thematic forums, such as the EMO Economic Forum, were held, bringing together representatives from key user industries including automotive, aerospace, and medical technology to discuss economic and technological challenges, share strategic thinking, and present best practices (Figure 3).

In addition, EMO 2025 introduced the “Partner Country” concept for the first time, with the theme “Partner Country Canada @ EMO2025.” Canadian manufacturers showcased their products and services in Hall 12, highlighting international cooperation and close inter-industry connections (Figure 4).

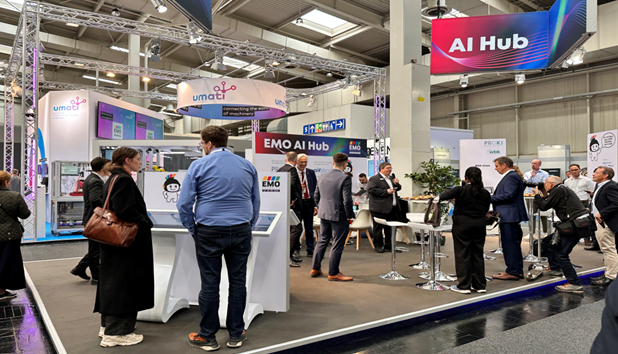

Theme 2: Automation and Artificial Intelligence as Key Drivers of Future Machine Tool Development

With the restructuring of global value chains and international labor division, the manufacturing industry faces rising costs, talent shortages, and increasing sustainability requirements. EMO 2025 adopted “Automation, Sustainability, Digitalization, and Artificial Intelligence (AI)” as its core themes, presenting diverse solutions that demonstrated how automation can improve efficiency and quality while reducing reliance on manpower, making it a key technology for manufacturing transformation.

To this end, special thematic zones, “AI + Digitalization” and “AI Hub @ EMO2025,” were established in Hall 6 (Figure 5), presenting application examples and prototype solutions of AI in metalworking (Figure 6). Among them, the German Machine Tool Builders’ Association (VDW) collaborated with Aachen-based company aiXbrain to develop the exhibition-exclusive chatbot “Emil” (Figure 7), which uses generative AI to help visitors instantly query key exhibition areas and event information.

ProKI-Aachen also demonstrated AI vision-assisted automated component insertion on printed circuit boards (Figure 8).

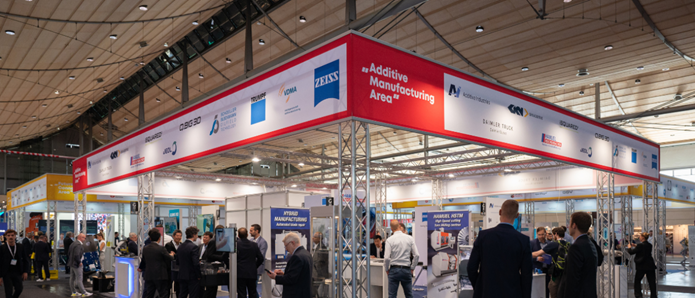

Theme 3: Additive Manufacturing (Metal 3D Printing) Becoming an Integral Part of Machine Tool Processes

In the past, metal 3D printing was limited to prototyping due to material technology constraints. With advances in manufacturing technology, metal additive manufacturing has now evolved to support full-scale production processes. In the future, metal machining processes are expected to adopt direct or indirect metal 3D printing technologies to enable Rapid Product Development (RPD).

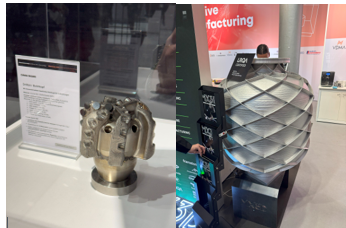

Accordingly, a dedicated “Additive Manufacturing” theme area was established in Hall 12 at EMO 2025 (Figures 9 and 10), demonstrating concepts of integrating metal 3D printing into production workflows. The exhibition also presented metal 3D-printed product cases completed by various machine tool manufacturers (Figure 11).

Theme 4: Giving New Life to Existing Equipment under the Concept of Sustainable Manufacturing

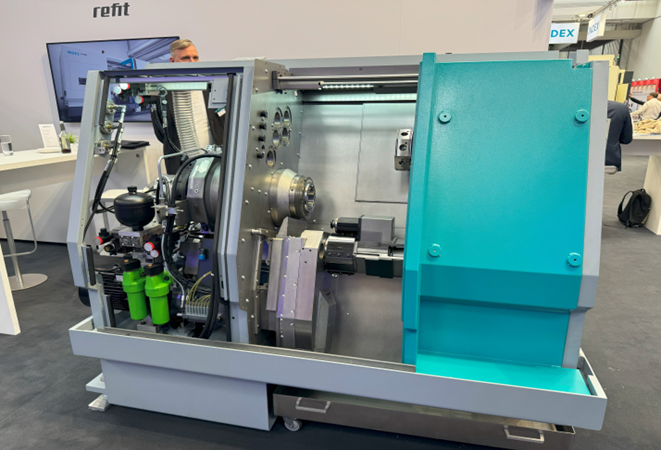

Under the pressure of tariffs and economic uncertainties, manufacturers have become more conservative in equipment investment and increasingly emphasize the “sustainable use” of machine tools. Instead of purchasing new machines, many companies prefer to extend equipment life and enhance performance by replacing key components such as CNC systems and Industry 4.0 controllers, achieving higher precision, stability, and digital monitoring capabilities.

For this purpose, EMO 2025 established a “Sustainable Manufacturing” theme area in Hall 14 (Figures 12 and 13). Major companies such as DMG MORI and GROB demonstrated legacy machine upgrade cases (Figure 13), showing how replacing drives and motors can reduce energy consumption and carbon emissions. Upgraded equipment not only meets current safety regulations and standards but also improves operational safety and corporate sustainability competitiveness. INDEX also展示 … (Figure 14) demonstrated legacy machine maintenance and retrofit services.

III. Technology Focus

At EMO Hannover 2025, it was evident that European manufacturing is promoting a new wave of industrial upgrading and structural transformation through the integration of high-precision machine tools and digital technologies.

(1) Aerospace Manufacturing Evolution: High-Precision Five-Axis and Multi-Task Machining Leading the Trend

The extreme requirements for precision and stability in the aerospace industry have made high-rigidity five-axis machining the core focus of major manufacturers. At EMO 2025, Swiss company Starrag showcased a full-scale aircraft landing gear system (Figure 15), one of the most demanding products in aerospace manufacturing.

Starrag demonstrated high-dynamic machining of aerospace structures using the Sprint Z3 milling head. The Sprint Z3 is a powerful milling head capable of simultaneous 5-axis machining, achieving high machining accuracy at maximum swivel angles, ensuring excellent surface quality. It is used for aircraft landing gear struts, connectors, and complex aluminum alloy structures and complies with EASA aerospace structural part standards and certification processes.

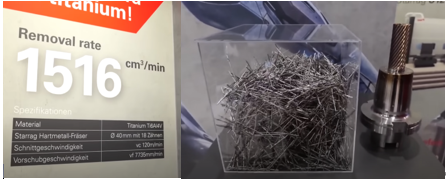

Starrag also presented the S1250 high-performance five-axis hydrostatic machining center, demonstrating an ultra-high titanium alloy removal rate of 1,516 cm³/min, capable of handling high-efficiency heavy cutting applications such as aerospace structural parts and landing gear.

(2) Rise of Defense Applications: A New Growth Engine for European Manufacturing

As the European automotive industry faces the impact of electrification and declining traditional metal-cutting demand, manufacturers are seeking new growth drivers. Exhibitions showed that many German machine tool and component manufacturers are rapidly shifting toward aerospace, defense, and energy equipment markets, forming a new pattern of “defense-driven high-end manufacturing.”

Many German exhibitors showcased defense-grade manufacturing solutions emphasizing “high-mix, low-volume, high-reliability” flexible manufacturing capabilities. For example, the GROB G550T five-axis mill-turn center features dual-mode control for heavy cutting and high-speed milling, suitable for manufacturing key components for tanks and defense systems.

The GMP300 liquid metal printing machine uses aluminum alloy wire feedstock, which is cheaper than powder materials and offers higher printing speed, emphasizing single-piece and small-batch production of aluminum alloy aerospace structural parts.

EMAG presented its newly developed ECM Boost technology, which optimizes pulse waveforms to maintain uniform current density, improve material removal rates, and suppress stray electric field effects. This enables machining without a heat-affected zone, without tool wear, and with high geometric accuracy. At EMO 2025, EMAG demonstrated this technology in precision gun barrel manufacturing for artillery ammunition, highlighting its strong defense manufacturing capabilities.

(3) AI and Digital Twin: Building the Smart Brain of Aerospace-Grade Manufacturing

One of the major highlights of EMO 2025 was the practical implementation of AI and Digital Twin technologies. Siemens demonstrated a comprehensive digital twin solution using a Rolls-Royce aircraft engine oil pump as a sample, connecting design, simulation, machining, and inspection stages, allowing engineers to update process models in real time in the cloud and automatically generate corrected machining paths, significantly shortening product introduction time.

Table 2. Benefits of AI-Enhanced Functions in Siemens System Modules

| Module | Function | Benefits After AI Integration |

|---|---|---|

| Teamcenter AI Copilot | Lifecycle PLM platform linking design, manufacturing, and maintenance data | Builds engineering knowledge graphs and automatically recommends design workflows and error correction suggestions |

| NX AI Assistant | Integrated CAD/CAM/CAE platform supporting generative design and simulation | AI assistant predicts geometry selection, topology optimization, performance prediction, and batch operations |

| Mendix AI Builder | Low-code platform for rapid AI deployment | Drag-and-drop integration of computer vision and prediction models without programming background |

| SIMIT + Simcenter AI | Digital twin simulation platform for virtual commissioning and multiphysics simulation | AI-driven virtual testing, fault prediction, and process optimization |

| Industrial Copilot for TIA Portal | Provides APIs to support programmable control of automation engineering workflows | Generative AI assistant supporting code generation and fault diagnosis |

The debut of the HEIDENHAIN TNC7 controller also marked a new stage in manufacturing intelligence. It introduced an AI chatbot into the programming environment, customized specifically for the vTNC7 programming system. Users can interact via natural language, and the system provides real-time operation tips, program editing suggestions, and can automatically generate NC code in Klartext syntax, significantly improving programming efficiency and accuracy.

The TNC7 also supports on-machine measurement and dynamic simulation, combined with AI algorithms to automatically identify sources of machining errors, enabling “virtual trial cutting” and “self-learning compensation” functions. These technologies have high strategic value in aerospace and defense industries where zero-tolerance processes are required.

Fraunhofer CCIT demonstrated a smart manufacturing architecture that combines edge AI, automated model generation, secure data exchange, and energy efficiency analysis, showing a modular technology stack from machine level to cloud. This framework supports tool monitoring, process optimization, and energy management, and provides a standardized technical blueprint for future Factory-X and AI-driven manufacturing.

IV. Conclusion

EMO Hannover 2025 not only revealed the harsh winter facing European manufacturing but also highlighted the determination of the machine tool industry to transform amid adversity. Facing global supply chain restructuring, energy policy pressures, and low-price competition from China, European and Asian manufacturers are adjusting their strategies, shifting from pure equipment supply to integrated solutions, and actively entering aerospace, defense, and high value-added industries, demonstrating resilience in seeing “crisis as opportunity.”

For Taiwan, this exhibition serves as a mirror, reminding the industry to move away from a purely cost–performance-oriented model and get closer to market and customer needs. Starting from end-use applications, Taiwanese companies should provide total machining solutions, strengthen high-precision and high-reliability technologies, and boldly introduce smart manufacturing and green energy-saving innovations. Only through technological upgrading and stronger market linkages can Taiwan find new footholds in the international market, define its own positioning in global competition, and embrace the next wave of growth opportunities.