The 2nd Machine Tool Industry Energy Label Assessment: Progressing Towards the 2050 Net-Zero Emissions Goal

Following the successful execution of the inaugural "Machine Tool Industry Energy Label" assessment at TMTS 2024 (Taiwan International Machine Tool Show), the Taiwan Machine Tool & Accessory Builders' Association (TMBA) received widespread positive feedback from the industry. Machine tool and component manufacturers have continuously invested in green technology R&D and improvements. Therefore, the TMBA has continued the effort by organizing the 2nd Machine Tool Industry Energy Label Assessment to identify energy-efficient machine tools or components, assisting end-users in their selection process.

The application period for the 2nd Energy Label Assessment opened in September. During this time, the TMBA's E Committee simultaneously worked on formulating Product Category Rules (PCR) to establish standards for carbon footprint calculation. The committee also hosted the first domestic training series on ISO 14955 (Energy efficiency of machine tools and components), helping members adopt international design standards and align with global practices.

This second assessment built upon the first, adding a new evaluation category: "Energy-Saving Supply Chain." This category aims to encourage machine builders to lead by example, driving their supply chains toward collective carbon reduction, or to recognize components/accessories that significantly assist machine builders in achieving energy efficiency and carbon reduction.

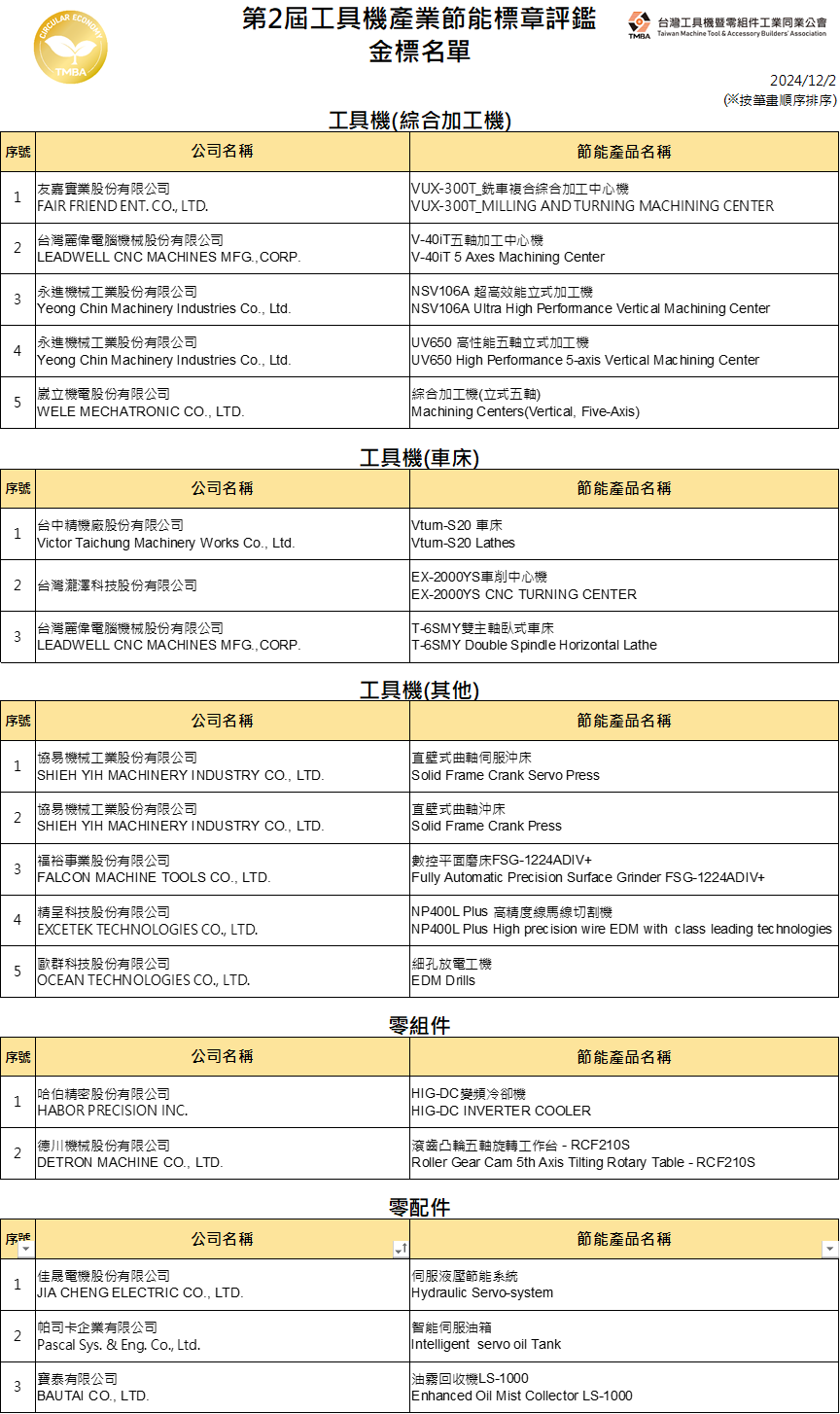

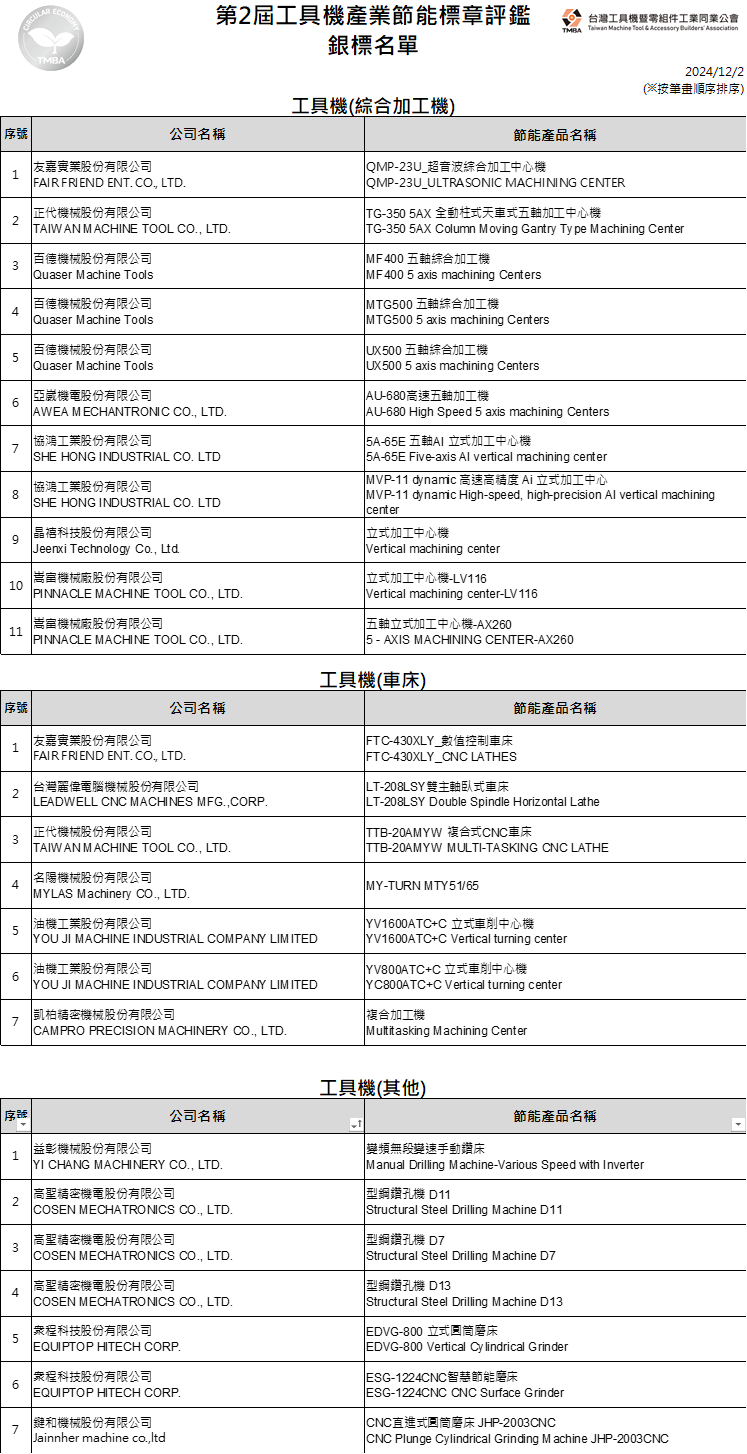

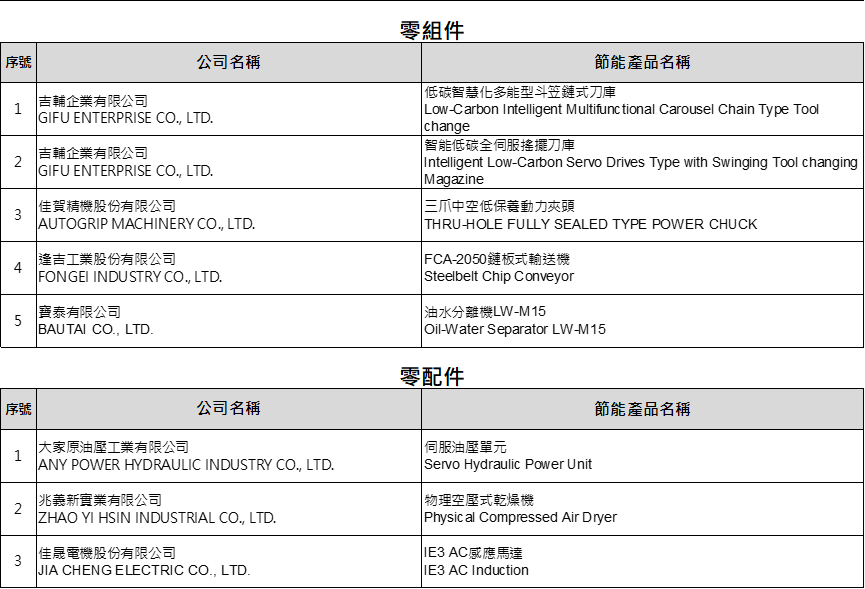

The assessment was categorized into five groups based on the PCR concept: Machining Center, Lathe, Press/Drilling/EDM/Grinding (combined group), Components, and Accessories. After evaluation by expert review committees from different specialized fields, 18 Gold Label products and 33 Silver Label products were selected.

All Silver Label and above products in the 2nd assessment feature a high degree of energy-saving design improvements. Gold Label products demonstrated compliance with the improvement effectiveness of ISO international standards or customer verification. For instance, machine builders such as Ying Han Technology, Victor Taichung Machinery, Takisawa Taiwan, Goodway Machine, Foou Yuh Industries, Kingsu Technology, and O-Kuma Technology all obtained the ISO 14955 certification. Their energy saving effect is at least 20% higher compared to the previous generation model. Notably, Ying Han Technology, Victor Taichung Machinery, and Takisawa Taiwan used a modular design combined with unit-level energy-saving improvements and measurement, allowing the solution to be replicated across other models, while also reducing carbon emissions from upstream suppliers' process conversion and material preparation.

Ying Han Technology, Victor Taichung Machinery, and Seyi Machinery took the lead in formulating the industry's PCR and calculating Product Carbon Footprint using ISO 14067, building a carbon reduction supply chain driven by major players. Component manufacturer Dexter Machinery assisted Takisawa Japan in obtaining the ISO 14955 certification. Accessory providers Jia Cheng, Pascal, and Baotai demonstrated "small achievements with big impact," serving as energy-saving suppliers for many machine builders in this assessment and playing a crucial role in overall machine improvement. Habor Precision, Fair Friend Group (FFG), and Victor-Top Work achieved significant energy saving and carbon reduction results through innovative R&D design combined with verification by domestic and international customers.

According to the "Reference Handbook for the Machine Tool Industry to Address Carbon Reduction and Sustainable Management" published by the TMBA in 2022, up to 95% of a machine tool's environmental impact occurs during the end-use phase. Therefore, selecting energy-efficient machine tools or components can help state-owned enterprises or metal processors save electricity and reduce carbon emissions, thereby propelling Taiwan toward the 2050 Net-Zero Emissions goal!