TIMTOS 2025 Taipei International Machine Tool Show A Closer Look at the Award-Winning Products from the 17th Machine Tool "Research, Development, and Innovation Product" Competition (Part1)

As spring arrives in 2025, with flowers blooming and green shoots emerging, all industries are gearing up, hoping for an early economic recovery. With signs of a ceasefire emerging in Eastern Europe and the Middle East, the demand for the "mother of industry," machine tools, is expected to increase. Both existing markets in Asia, Europe, and the Americas, as well as emerging regional markets, are critical battlegrounds.

The Taipei International Machine Tool Show (TIMTOS 2025) will be held from March 3rd to 8th, running for six consecutive days at the Taipei Nangang Exhibition Center, Halls 1 and 2, and the Taipei World Trade Center (TWTC) Hall. Exhibitors will showcase machine tools and related components that best meet the demands of the emerging new energy market.

During the exhibition, the 17th Machine Tool "Research and Development Innovation Product" Competition will be held, divided into five categories:

-

Machining Centers and Machining Unit Category

-

CNC Lathes and Machining Unit Category

-

Other CNC Machine Tools and Machining Unit Category

-

Key Components for Numerical Control Machine Tools Category

-

Energy Saving, Carbon Reduction, and Smart Product Innovation Award (for all entries)

This competition serves to highlight the R&D achievements of participating companies.

Since the conclusion of TIMTOS 2023, numerous manufacturers have been planning the R&D and production of their machines to enter the 2025 competition. Following the preliminary and secondary selections, 31 companies with 33 entries advanced to the final round. The final judging phase formally takes place during the exhibition, with the judging panel consisting of industry leaders, experts, and academics in the machine tool sector.

As TIMTOS 2025 opens, all participating companies strive to capture the attention of both judges and buyers. During the scoring process, entrants demonstrate their machines' optimal performance, market relevance, and unique patents. They spare no effort in communicating their machine's advantages to the judges. The judging panel assigns scores based on the following criteria: (1) Innovation, (2) Intelligence and Practicality, (3) Green, Energy Saving, and Sustainability, (4) Structure, Precision, and Quality, (5) Market Feasibility, (6) Aesthetics, and (7) Other factors.

Ultimately, one machine is selected for the Grand Prize (Special Excellence Award), and several winners and honorable mentions are chosen for each machine type, as shown in Table 1.

| Award | Company Name | Product Name |

| Grand Prize | Fatek Technology Industrial Co., Ltd. (FEMCO Group) | BMC-135FTS High-Load Milling-Turning Compound Boring Machine |

| Machining Centers and Machining Unit Category | ||

| Winner | Wele Mechatronic Co., Ltd. | UG630-AWC Smart Flexible Manufacturing Center |

| Honorable Mention | Dah Lih Machinery Industrial Co., Ltd. | DMC-650 Gantry Machining Center |

| Honorable Mention | Fair Friend Enterprise Co., Ltd. | VUX-300T Mill-Turn Compound Machining Center |

| Honorable Mention | Kao Ming Machinery Industrial Co., Ltd. | KMC-436HAX.E High-Rigidity Smart Five-Face Gantry Machining Center |

| CNC Lathes and Machining Unit Category | ||

| Winner | L&L Machinery Industry Co., Ltd. | LLB-M High-Value Smart Super-Heavy Moving Column Horizontal Multi-Axis Turn-Mill Cutting Center |

| Honorable Mention | Wele Mechatronic Co., Ltd. | VTC1612-CW Vertical Turning and Milling Compound Machine |

| Honorable Mention | Tongtai Machine Tool Co., Ltd. | TMS-1800S Compound Turning Center |

| Honorable Mention | Yida Precision Machinery Co., Ltd. | MT-210 Small Multi-Axis Compound Machining Unit Low-Carbon Innovation Application |

| Other CNC Machine Tools and Machining Unit Category | ||

| Winner | Quan Xin Precision Industrial Co., Ltd. | NP600Plus Energy-Saving Smart Linear Motor Wire Cut EDM |

| Honorable Mention | Ecoca Corporation | NP600Plus Energy-Saving Smart Linear Motor Wire Cut EDM |

| Honorable Mention | CHING HONG MACHINE TOOL CO., LTD. | UA432L Green Energy All-in-One Linear Motor Wire Cut EDM |

| Honorable Mention | Hehe Machine Co., Ltd. | Laser Tube Cutting Machine (10-axis) + Tube End Chamfering and Deburring (SLT-80-FIBER Cell) |

| Key Components for Numerical Control Machine Tools Category | ||

| Winner | HIWIN Technologies Corp. | RCH-100E High-Speed EDM Milling Head |

| Honorable Mention | Gifu Enterprise Co., Ltd. | BT5036HSS5 Smart Low-Carbon All-Servo Swing Tool Magazine |

| Honorable Mention | Han Ding Technology Co., Ltd. | UTD30 Non-Contact Power Transmission High-Speed Spindle |

| Honorable Mention | Taiwan Soco Machinery Co., Ltd. | KA-WTS Smart Energy-Saving Cutting Fluid Tank |

| All Entries, Energy Saving, Carbon Reduction, and Smart Product Innovation Award | ||

| Special Award | Ecoca Corporation | NP600Plus Energy-Saving Smart Linear Motor Wire Cut EDM |

| Honorable Mention | CHING HONG MACHINE TOOL CO., LTD. | UA432L Green Energy All-in-One Linear Motor Wire Cut EDM |

| Honorable Mention | Fatek Technology Industrial Co., Ltd. (FEMCO Group) | BMC-135FTS High-Load Milling-Turning Compound Boring Machine |

| Honorable Mention | Gifu Enterprise Co., Ltd. | BT5036HSS5 Smart Low-Carbon All-Servo Swing Tool Magazine |

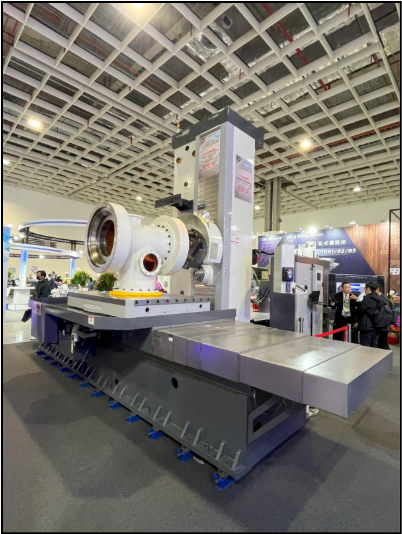

🏆 Grand Prize Winner

The Grand Prize was awarded to Fatek Technology Industrial Co., Ltd. (FEMCO Group) for their 'BMC-135FTS High-Load Milling-Turning Compound Boring Machine' . This product also received an Honorable Mention in the "Energy Saving, Carbon Reduction, and Smart Product Innovation Award (for all entries)" category, making it a major highlight among this year's submissions.

The BMC-135FTS was developed with a modular design to meet market demand for heavy-duty cutting, featuring a high-load capacity worktable, and ease of assembly and maintenance. A key innovation of this machine is its high-load worktable equipped with a turning faceplate. Traditionally, complex large part processing often leads to errors and requires multiple machines. Fatek's design allows for boring, milling, and turning operations to be completed in a single setup, reducing processing errors resulting from multiple operations.

Based on hydrostatic technology, the machine detects oil chamber pressure and, after calculation and conversion, the controller automatically determines the worktable's load weight. The controller then analyzes and calculates this data to apply variable compensation for displacement errors, thereby improving machining accuracy.

Fatek also developed an in-house Augmented Reality Machine Tool Management System. This system constructs various machine tool information in augmented reality on a cloud server, allowing clients to access it via mobile devices. The system includes an AR parts manual and AR troubleshooting guidance. If an equipment issue arises, a QR code generated instantly on the controller screen links the mobile device to the cloud, using the AR information for guided troubleshooting. This feature reduces the risk of machine interference, prevents crashes due to programming errors, and improves machining quality. Software simulation of the processing effect allows for parameter and condition adjustments without moving the machine, significantly reducing the cost of trial and error in actual operation.

The machine is primarily used for processing components in the petrochemical industry, large pumps, and various components related to water and power grid piping and valves. The upper body's off-white and light gray colors contrast with the carbon black machine base, clearly demarcating moving and fixed areas to enhance operational safety. Responding to the growing customer demand for complete collection of chips and cutting fluid, Fatek developed a semi-enclosed enclosure and operator splash guard to prevent splashing and facilitate collection. Interlock switches are installed on the sliding doors to ensure operator safety.

|

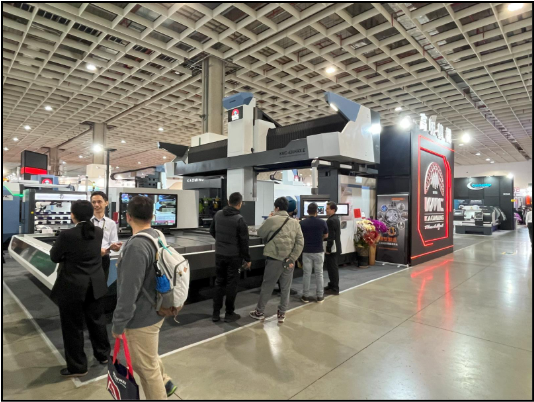

⚙️ Machining Centers and Machining Unit Category

Winner - Wele Mechatronic

Wele Mechatronic Co., Ltd.'s entry, the 'UG630-AWC Smart Flexible Manufacturing Center', won the Winner award in the Machining Centers and Machining Unit category . This winning product features a smart high-efficiency AWC flexible manufacturing unit (with a modular design allowing easy expansion after the main unit leaves the factory) and is equipped with a 120-tool magazine (expandable to 150 tools). This setup meets the market trend toward highly automated mass production.

The machine utilizes a large number of robust, in-house developed and manufactured key components. It features a 15,000 rpm high-speed built-in spindle with an optimal volume-to-weight-to-performance ratio, enhancing dynamic characteristics. The B and C axes rotary tables are driven directly by Torque motors, providing excellent rotational positioning and repeatability. A high-torque, powerful braking clamping system is used, along with locally sourced high-rigidity cross-roller bearings, significantly boosting product durability. The automatic pallet changer features a mechanical spring-clamping system for its pallet origin mechanism, drastically reducing the energy consumption associated with hydraulic motor activation. The AWC flexible manufacturing unit is fast and reliable, utilizing an all-electric servo motor paired with a proprietary reducer, which allows for smaller motor specifications. The expandable 120-tool turret, modularly designed to be expandable to 150 tools, also uses an all-electric servo motor with a proprietary reducer drive, leading to reduced motor size, energy savings, and faster operation. In-house developed smart scheduling software addresses situations like batch production or urgent inter-order insertions.

The smart and practical operator interface includes 7 key functions: (1) Tool Magazine Management, (2) Tool Measurement, (3) Workpiece Measurement, (4) Calculator, (5) I/O List, (6) Tool Change Recovery, and (7) Full Machine Motor Information. Through smart sensing and calculation, the machine can determine the load on the transport mechanism and automatically adjust its speed, positioning at the optimal speed and shortest path, and then transporting the pallet in the safest manner. Optimized transport sequencing maintains a First-In, First-Out (FIFO) continuous processing flow, eliminating the need for manual judgment and wasted waiting time. Urgent inter-orders can be easily set, with both entry and exit given the highest priority, allowing for simple response to sudden rush demands and offline maintenance.

The machine's exterior design focuses on a minimalist, compact structure. The ergonomic semi-circular workstation allows the operator to effortlessly load, unload, and clean workpieces. Incorporating the TPS (Toyota Production System) lean manufacturing concept, the machine features structural modularization and process innovation, simplifying unnecessary machining and sheet metal work, and greatly improving assembly process efficiency. The silver and black thin-textured paint finish allows for localized touch-ups, making it environmentally friendly and saving labor time.

|

Honorable Mention - Dah Lih Machinery Industrial

Dah Lih Machinery Industrial Co., Ltd.'s 'DMC-650 Gantry Machining Center' won an Honorable Mention in the Machining Centers and Machining Unit category . With the machine tool trend moving towards high speed and high precision, traditional C-frame structure machine tools are increasingly unable to meet customer precision demands. With the booming development of AI, High-Performance Computing (HPC), Electric Vehicles (EV), IoT, and 5G infrastructure, the need for high-precision machining is growing, particularly in consumer electronics, automotive semiconductors (millimeter-wave radar, ADAS high-level driver assistance system chips), and communication industries. This award-winning machine is designed to meet the demands of these markets.

Dah Lih developed the TBM Tool Breakage Monitoring System based on the principle of a "machine tool that can self-learn and monitor tool breakage." By monitoring the spindle's virtual current, the system determines if a tool has broken and immediately stops the machine's cutting action. This feature is applicable for detecting tool breakage during milling, drilling, and tapping processes. It also allows for multi-stage learning within the program, making program arrangement more convenient for the operator (Patent No.: M634020).

In terms of intelligence, the machine offers practical operational features for users, including AI learning, big data, energy saving and carbon reduction, and adaptive cutting, providing customers with high-quality, high-value content. Intelligent features include: (1) Adaptive Cutting Feed Control, (2) Machining Program Analysis, (3) Lubricant Consumption Statistics, (4) Tool Life Diagnosis, (5) Single Machine Utilization Rate, and (6) Drilling Chip Breaking.

For Smart Energy Saving Technology, the standby energy-saving function allows the customer to set a time period. The system automatically determines if the machine is idle during this period. Once the set time is reached, the system automatically shuts down the hydraulic, cooling, and servo systems to achieve energy savings. Standard 8-hour standby consumption is about 7 kWh, while using the standby energy-saving function reduces this to about 3 kWh, a 57% reduction in power consumption. Power consumption is visualized, allowing customers to understand the energy consumption of the servo axes, spindle, and motors via a dedicated screen. The total carbon emissions and total power consumption generated during the machining process are digitized on the interface, achieving the goal of carbon emission visualization. Users can also review historical trend data through the query function.

The machine's exterior adopts the corporate identity colors of blue, white, and black, accented by a blue glowing LED nameplate, the representative color of Dah Lih Machinery. The machine model is painted in clean lines on the sheet metal guard, easily visible when the operating door is both closed and open. This gantry model also offers X and Z axes with box ways for users requiring a better surface finish on the processed part. It is equipped with a load-relief guide device to reduce the moving load of the head saddle, providing the competitiveness of a small-to-mid-range, high-end machine tool with a high-strength, high-precision structure.

|

Honorable Mention - Fair Friend Enterprise

Fair Friend Enterprise Co., Ltd.'s 'VUX-300T Mill-Turn Compound Machining Center' won an Honorable Mention in the Machining Centers and Machining Unit category . This machine is capable of metal cutting using both milling tool rotation and turning workpiece rotation. It allows users to machine more complex parts without changing equipment, significantly shortening the processing time and better meeting current market demands. The machine incorporates two smart elements: "Tool Life Evaluation Technology" and "Application of Cyber-Physical Systems for Workpiece Surface Texture Analysis," increasing the added value of the equipment and boosting its global market competitiveness. The machine also utilizes three new utility model patents: "Coolant Tank Swirl Self-Cleaning," "Direct-Drive Spindle Disc Brake System," and "Carbon Emission Monitoring."

Fair Friend has invested significant R&D resources, integrating IoT, big data, and AI technologies to provide intelligent services and solutions focused on energy saving, carbon reduction, digital maintenance tracking, and production data traceability. This builds the foundation and capability for smart machinery, enhancing the intelligent application elements of the VUX-300T. Specific smart energy-saving measures, in line with the net-zero carbon emission trend, include:

-

Total Machine Power Statistics: Tracks daily electricity consumption and reviews historical energy consumption.

-

ECO Mode: Activates an energy-saving mode and calculates the energy saved.

-

Smart Machine Maintenance:

-

Diagnosis/Health Check: Automatic self-check upon startup ensures machine health; real-time health checks during operation proactively alert for abnormalities.

-

Life Management: Tracks usage time and predicts spindle life.

-

The machine structure employs a modular design covering (1) Product Design, (2) Component Design, (3) Manufacturing Process, and (4) Product Testing. The body is an extended, integrated design from their 5-axis machine, making it particularly suitable for the following industries, considering various regional markets: semiconductor, 3C communications, biotechnology and medical, energy, precision molds, robotics, and drones. Operators can approach the worktable (the distance from the center of the worktable to the operator is 480mm), making it easy to change tools and set up workpieces. The developed Tool Life Evaluation System presents the real-time status of tool life through a visual interface. By integrating a cutting force model with a torque stacking method, only one model (A parameter) needs to be established. Tool life can still be estimated even with processing parameter variations within $\pm 20\%$ (Fz) without the need for re-modeling.

|

Honorable Mention - Kao Ming Machinery Industrial

Kao Ming Machinery Industrial Co., Ltd.'s 'KMC-436HAX.E High-Rigidity Smart Five-Face Gantry Machining Center' won an Honorable Mention in the Machining Centers and Machining Unit category . The R&D strategy for this machine aimed to create a smart five-face gantry machining center capable of processing difficult-to-cut materials and large workpieces in the aerospace industry. The main improvements were twofold: first, enhancing the spindle system performance and machine rigidity, and second, equipping it with three smart functions, specifically providing a high-performance machining solution for aerospace part cutting requirements.

The machine is equipped with three smart functions developed in collaboration with the Industrial Technology Research Institute (ITRI): "Smart Auxiliary Assembly Monitoring Technology," "Equipment Health Monitoring Technology," and "Machining Dynamic Monitoring Technology." Detailed sub-items include:

-

Smart Auxiliary Assembly Monitoring Technology:

-

Spindle Run-in Monitoring System: Monitors gear and bearing assembly status, quantifying to ensure quality consistency.

-

Visualized Anomaly Exclusion Guidance Technology: Based on 3D model digitalization and visualization of assembly, reducing maintenance difficulty.

-

-

Equipment Health Monitoring Technology:

-

Key Component Status Monitoring System: Combines artificial intelligence and sensors to monitor component aging.

-

Full-Time Lubrication System Monitoring Technology: Monitors the temperature and vibration of the lubrication system to ensure operational performance.

-

-

Machining Dynamic Monitoring Technology:

-

Smart Temperature Control System: Combines fuzzy control and artificial intelligence to adaptively adjust temperature, maintaining equipment stability.

-

Cutting Dynamic Control System: Uses vibration and current signals to monitor the machining status in real-time, increasing production yield.

-

The machine uses an energy-saving hydraulic system, reducing motor power from 10HP to 3HP, achieving a 56% reduction in energy consumption. The entire machine uses IE3 high-efficiency motors, meeting EU environmental standards. The lifespan of key component gears is doubled, which also helps reduce carbon emissions. The market for large, difficult-to-cut aerospace parts will be significant for five-face gantry machining centers over the next decade. To meet aerospace industry demand, Kao Ming developed the KMC-HAX.E series based on their five-face gantry machining center technology, specifically designed for large, difficult-to-cut aerospace materials, providing high-precision, large travel, high-rigidity, and multi-angle five-face machining capabilities.

The Kao Ming logo is engraved on the spindle head and the top of the CRT, and aluminum extrusions replace steel for lightweighting and a premium feel. A wrap-around light panel replaces the traditional warning light, enhancing the machine's technological look and visual alerts. Conveyor trim colors and shapes unify the overall style. The product utilized a complete PLM (Product Lifecycle Management) development design, with the proportion of localized components reaching 74.5% and conforming to 9 TMBA industry standards. Standardization and modularization of parts were considered from the initial design phase, with each module unit having expansion capability.

|

🔩 CNC Lathes and Machining Unit Category

Winner - L&L Machinery Industry

L&L Machinery Industry Co., Ltd.'s entry, the 'LLB-M High-Value Smart Super-Heavy Moving Column Horizontal Multi-Axis Turn-Mill Cutting Center', won the Winner award in the CNC Lathes and Machining Unit category . Responding to the trend for complex machining, this machine was developed for the multi-axis machining of large, long shaft components in industries such as offshore green energy wind turbine components, defense industry, heavy metal processing, and aerospace parts that require complex, precision machining.

The focus of the R&D was on the supporting structure for super-heavy workpieces with diameters of $1,600 \text{ to } 2,400 \text{ mm}$ and weights of $20 \text{ to } 40 \text{ tons}$. The moving column structure includes a vertical column and a spindle carriage. The Y-axis feed mechanism uses left and right ball screws and linear guides for better stability and machining accuracy. The carriage module can be integrated with A and B axis rotation mechanisms in the future to provide combined processing such as multi-axis simultaneous milling, turning, grinding, boring, and gear hobbing.

In terms of intelligence and practicality, a diagnosis algorithm and intelligent system (L&L SmartSystem) were developed to help operators learn quickly and use the machine easily: (1) State Self-Diagnosis, (2) Machining Assistance System, and (3) CPS Maintenance Assistance System. The bed structure was lightweighted using CAE structural analysis, resulting in a 14% reduction in weight while maintaining the same structural strength. This is estimated to reduce carbon emissions equivalent to approximately $4,123 \text{ kWh}$ of electricity consumption during transportation, raw material, and manufacturing processes.

The column structure adopts a BOX-in-BOX symmetrical box structure. The left and right hollow columns form a rectangular closed box, with strategically placed reinforcing ribs to enhance the body's anti-bending and anti-torsion rigidity. A whole-machine dynamic analysis was conducted to establish the relationship between the machine's overall dynamic characteristics and the characteristics of individual component modules, thereby standardizing the joint assembly process and improving machine quality.

The sale price of this machine is approximately one-third to one-half that of its main European competitors, and the machine's current technical level is comparable to leading European brands, offering a competitive advantage with its high cost-performance ratio. The machine development involved collaboration with component manufacturers to establish a domestic industry-academia-research machine tool R&D team. Cooperation between universities and domestic manufacturers also helps cultivate mechanical expertise, encouraging universities to focus on training talent needed by enterprises and providing an opportunity to transform university lab research into new, market-competitive products.

|

Honorable Mention - Wele Mechatronic

Wele Mechatronic Co., Ltd.'s entry, the 'VTC1612-CW Vertical Turning and Milling Compound Machine', won an Honorable Mention in the CNC Lathes and Machining Unit category . The development background for this award-winning product includes: (1) Market Response: Gathering customer expectations from Europe and the US for this product, addressing the urgent demand for a cost-competitive, high-performance medium-sized vertical turn-mill center. (2) Target Applications: Dedicated to providing highly reliable, cost-competitive, domestically produced products for the energy and aerospace industries, meeting stringent processing requirements. (3) Enhancing International Competitiveness: Entering the large-scale turn-mill compound machining sector to challenge German and Japanese brands in the European, US, and Chinese markets.

Intelligence and Practicality features include:

-

Smart Flexible Beam-Type ATC Tool Magazine: The beam-type tool magazine drive is controlled by a servo motor, replacing the traditional hydraulic system, reducing energy consumption, and ensuring accurate tool changes.

-

Wele iSmarTune Electric Control Software: Provides practical customer functions such as calculator, full machine motor information, utilization rate information, and maintenance information.

-

Automatic Hydraulic Clamp Adjustment: The hydraulic clamps feature automatic adjustment, allowing for precise clamping that adapts to changes in workpiece shape.

-

Novel and Unique Processing Application: Equipped with a zero-backlash mechanism and Cs-axis control function to achieve an adaptive feed adjustment mechanism that can accommodate and suppress vibration during thread milling.

The machine adopts a streamlined, modern design style, reducing the overall footprint by 40%, with a simple, compact structure that maximizes space utilization. The tool magazine's use of a servo motor instead of a traditional hydraulic system significantly reduces energy consumption and the waste oil generated by hydraulic equipment, aligning with green manufacturing requirements. The overall energy-saving and carbon reduction design conforms to international green manufacturing standards, significantly reducing the carbon footprint and supporting sustainable development. Machine power consumption monitoring allows customers to obtain power consumption information via the custom Wele interface to formulate energy-saving plans. The high-precision hydraulic clamp design provides stable and efficient clamping force, ensuring workpiece stability, reducing vibration, and improving machining accuracy, guaranteeing excellent performance under various heavy-duty processing conditions. The product has passed rigorous international standards, including EU CE and Taiwan TS safety certifications, ensuring compliance with global standards and providing customers with high-level safety and reliability, further boosting confidence in the global market.

|

Honorable Mention - Tongtai Machine Tool

Tongtai Machine Tool Co., Ltd.'s entry, the 'TMS-1800S Compound Turning Center', won an Honorable Mention in the CNC Lathes and Machining Unit category . Traditional production models involve breaking down processes and arranging multiple machines in a production line. Changing workpieces requires stopping the line to replace fixtures and tools, which is time-consuming and labor-intensive for customized products and non-mass-produced parts. To address this, the TMS-1800S Compound Turning Center was developed to complete the workpiece in a single clamping operation. This reduces the number of fixtures required and saves time and labor associated with line changeovers, meeting the needs of high-mix, low-volume production.

This machine is a highly integrated turn-mill compound processing equipment designed for modern manufacturing. It features multi-axis milling and multi-angle turning capabilities, achieving "processing completion in a single clamping" (process consolidation), which significantly shortens changeover time and reduces labor input, substantially boosting production efficiency. The research and application of smart manufacturing technology, integrating the NC and PC architecture platform with the intelligent software platform TIMS, provides users with convenient functional access. A key highlight is the in-house developed 3D anti-collision function. Using digital twin technology, the system predicts machine movement positions and performs collision risk checks, effectively preventing improper operation from damaging the machine or the operator. This function works in both manual and automatic modes, particularly suitable for high-mix, low-volume scenarios, ensuring consistent product quality during frequent changeovers. The AI assistant T-BOT further enhances operational convenience. Users can query machine status, tool information, and troubleshooting guidance via voice or text, significantly improving operational efficiency and problem-solving speed.

The slides for all axes adopt a large span and roller guide design, effectively improving stability during machining, reducing vibration, and maintaining precision. The B-axis transmission mechanism uses a Roller Cam design, featuring high rigidity, high sensitivity, and zero-backlash, ensuring precise angle control. Spatial accuracy compensation technology, based on ISO230-1/230-2 standards for checking geometric and positioning accuracy, utilizes precise measurement and data analysis to effectively compensate for linear and rotary axis errors, ensuring stable accuracy during machine operation.

|

Honorable Mention - Yida Precision Machinery

Yida Precision Machinery Co., Ltd.'s entry, the 'MT-210 Small Multi-Axis Compound Machining Unit Low-Carbon Innovation Application', won an Honorable Mention in the CNC Lathes and Machining Unit category . Yida independently developed the MT-210 8-axis turn-mill compound machining center. From the core software to the mechanism, everything was developed in-house, combining the functions of a lathe, milling machine, ATC (Automatic Tool Changer) system, and turret. This design meets diverse machining needs, realizing a "processing completion in a single setup" mode of operation.

Integrating lathe and milling functions, along with the ATC system, the machine is equipped with an 18-tool turret and a 16-tool disc-type magazine, shortening tool change time and significantly increasing production flexibility. Multi-process machining can be completed in a single clamping, substantially boosting production efficiency. The B-axis, CF-axis, and turret designs reduce weight and lubrication oil usage by 70%–80%, improving energy efficiency and lowering maintenance costs.

The patented coolant tank detection system provides real-time monitoring of coolant capacity, temperature, and pipeline flow anomalies, giving early warnings for abnormalities to ensure processing stability and extend equipment life. Through structural lightweighting and material optimization, the machine base uses a lightweight design, replacing the full cast iron base with iron components. While maintaining structural stability, this reduces material usage by approximately 30%, lowering production costs and reducing the material's carbon footprint. The energy monitoring system records equipment energy consumption in real-time, helping users optimize energy usage and lower long-term operating costs.

The machine adopts an ergonomic and octagonal design, breaking away from the traditional machine tool appearance, enhancing operational convenience and space efficiency. The minimalist line design showcases industrial aesthetics and high-tech features, appealing to customers who value efficiency and aesthetics. The market price is only one-sixth of imported foreign machines, offering an extremely high cost-performance ratio suitable for SMEs and the education market. Product development, quality control, and after-sales service are managed digitally, fulfilling digital management and ESG goals. The company actively implements the concepts of environmental protection and energy saving/carbon reduction, integrating sustainability into corporate operations and product design.

|

The award-winning products presented above are all developed by manufacturers to align with current trends. The current industrial development trajectory is largely driven by the government's "Climate Change Response Act" and the "2050 Net Zero Emissions" goal, formally affirming Taiwan's commitment to international sustainability. With the EU's Carbon Border Adjustment Mechanism (CBAM) and the US's Clean Competition Act (CCA) pending implementation, all machine tool manufacturers are moving toward ESG goals.

The next part of the article will continue to introduce the award-winning products in the Other CNC Machine Tools and Machining Unit Category and the Key Components for Numerical Control Machine Tools Category.