The Wave of Intelligent Transformation: AI Applications and Development Trends in Manufacturing

Preface

Artificial Intelligence (AI) refers to computer technologies that simulate human cognitive abilities. Since its proposal in the 1950s, AI has experienced two major downturns due to insufficient computing power and practical application challenges. Today, with the advent of deep learning and the gradual improvement of hardware supporting AI’s computational needs, AI has entered its third peak of development. Google CEO Sundar Pichai even stated that “the impact of AI may surpass that of fire and electricity.”

The launch of ChatGPT was a game-changer. Built on large language models (LLMs) with massive parameters, it significantly improved comprehension and creative content generation. Within just two months, ChatGPT’s monthly active users exceeded 100 million—a growth driven by widespread recognition of AI as an intelligent assistant. From defeating Go champions in specialized domains to becoming a practical everyday tool, AI’s evolution has been remarkable.

Why Manufacturing Needs AI

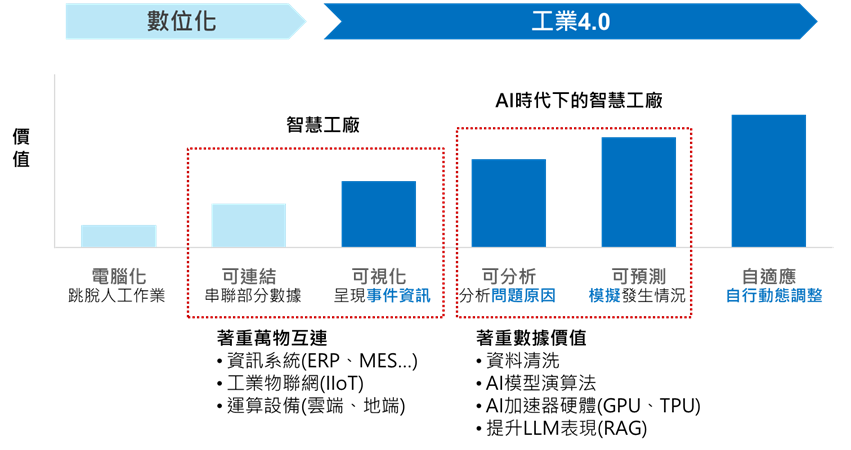

Global manufacturing continues to adopt new technologies and implement Industry 4.0 concepts, moving toward maturity. Traditionally, smart factories focused on digitalization, using Industrial IoT (IIoT) to monitor equipment, production lines, and plant operations for better process control and reduced time spent on repetitive status checks.

However, recent challenges—global inflation, rising production costs, and persistent labor shortages—have pressured manufacturers. Events like the pandemic, geopolitical tensions, and the Russia-Ukraine war disrupted production and supply chains. Major ICT brands now demand localized production, raising issues such as stable procurement, safety stock, and capacity-sharing among partners. As supply chains shift from long to short, manufacturers are relocating closer to customer markets, rebuilding local supplier networks, and investing in production facilities—all while facing challenges in replicating yield rates and managing cultural differences among employees.

These macroeconomic factors expose the limitations of traditional digitalized factories in three areas:

- Flexibility: Rule-based scheduling systems struggle to handle urgent or last-minute orders in volatile markets.

- Predictability: Digitalization reflects the “current” state, but manufacturers now need foresight to prevent future risks—something AI can deliver by uncovering hidden patterns in data.

- Complexity: Digital factories collect highly granular data (e.g., robotic arm parameters like status, timestamps, XYZ coordinates), but dashboards typically show only management-level KPIs. AI-driven smart factories transform unreadable raw data into meaningful insights.

In short, while digitalization unified management through transparency, AI-driven smart factories emphasize data-driven decision-making, enabling predictive and analytical capabilities.

|

Source: MIC (2024)

The Landscape of AI Applications in Manufacturing

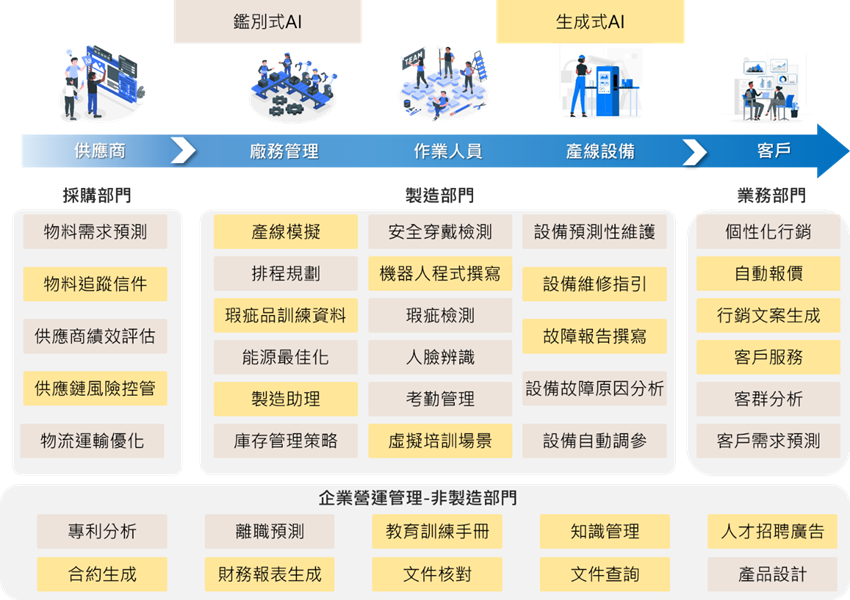

AI’s impact lies in optimizing operational efficiency, reducing costs, and even generating revenue. Manufacturing faces diverse challenges—classification (defect detection, spam filtering), clustering (market segmentation), sequence prediction (demand forecasting, inventory management, predictive maintenance), and generation (data synthesis, product design)—each matched to specific AI algorithms.

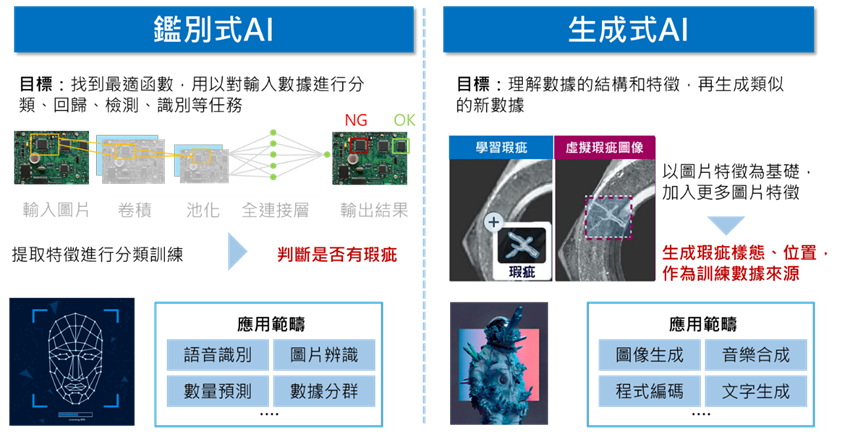

AI can be categorized into Discriminative AI (for classification and pattern recognition, e.g., speech and image recognition) and Generative AI (for creating data similar to training sets, e.g., text, images, video, code). These two approaches complement rather than replace each other, serving different scenarios.

Applications span all business processes—production, sales, HR, R&D, finance—across industries like electronics, metalworking, pharmaceuticals, textiles, and chemicals. Common use cases include:

- Supply Chain Management: AI predicts material demand based on orders, inventory, and lead times; Generative AI monitors news to assess supplier risks.

- Production Management: AI optimizes scheduling using workforce, machine status, and material data; Generative AI simulates production lines for optimal layouts.

- Customer Management: AI analyzes customer data for segmentation; Generative AI drafts quotes and emails based on order conditions.

- Operations: AI predicts employee turnover; Generative AI creates multilingual training manuals and compliance documents.

|

Source: MIC (2024)

|

Source: MIC (2024)

Case Study: AI for Product Defect Detection

Quality inspection is critical for yield control. Defects vary by product—e.g., soldering issues, deformation, corrosion, missing parts, dirt, scratches. Traditionally manual, inspections now use Automated Optical Inspection (AOI) and increasingly AI to reduce re-inspection labor. AI learns human judgment standards for OK/NG products via deep learning, offering consistent criteria and resilience to lighting variations compared to AOI.

Challenges include limited and imbalanced defect datasets, as real defects occur infrequently (e.g., 1% defect rate means 1 defect per 100 boards). Product lifecycle changes further complicate data collection.

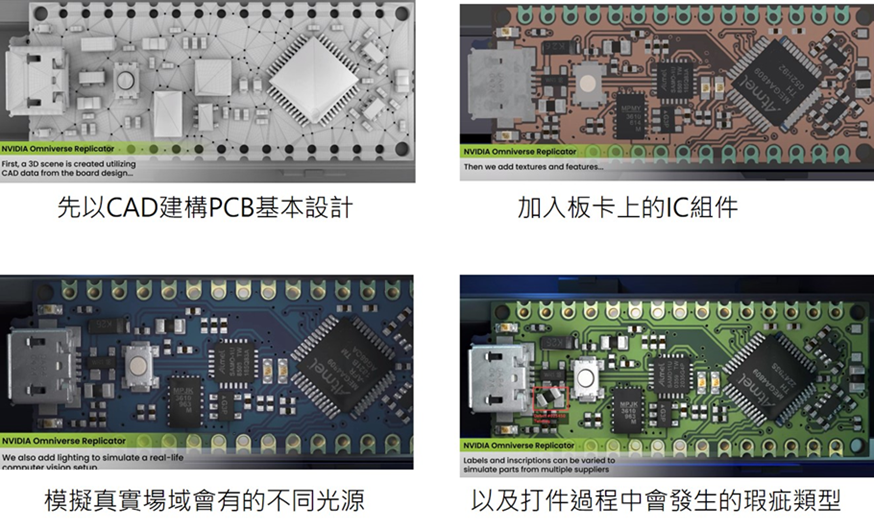

To address this, NVIDIA and Siemens use Generative AI to create synthetic defect images under realistic lighting and process conditions, simulating issues like tombstoning, twisting, missing components, and misalignment. This reduces reliance on real defective samples and accelerates dataset creation.

Taiwan’s MetAI demonstrated similar success: starting with 600 real samples yielded 62% accuracy; adding 1,400 synthetic samples raised accuracy to 88%, and 4,400 samples achieved 96%. Generative AI also automates defect labeling, cutting annotation time from 7 minutes per image to mere seconds. Overall, data collection and labeling time dropped from 10 months to half a month—a 95% reduction—speeding model deployment and reliability.

|

Source: NVIDIA,Siemens, complied by MIC (2024)

Guidelines for AI Adoption in Manufacturing

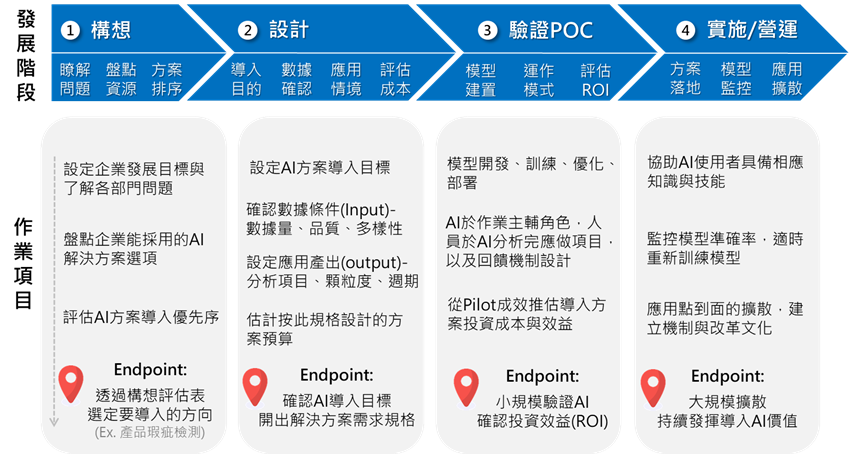

AI implementation involves four stages:

- Ideation: Define business goals, identify problems, assess AI’s benefits, and prioritize feasible solutions.

- Design: Specify problems, required data, analysis methods, timing, and ROI; set performance metrics.

- Validation: Test model effectiveness, interpret results, optimize, and confirm economic benefits before full deployment.

- Implementation: Integrate AI into workflows, manage organizational change, and continuously monitor and update models for sustained performance and scalability.

|

Source: MIC (2024)